Antibacterial anti-static polyacrylonitrile fibers and manufacture method thereof

A technology of polyacrylonitrile fiber and polyacrylonitrile, which is applied in the manufacture of conductive/antistatic filaments, fiber chemical characteristics, wet spinning, etc., and can solve problems such as fabric damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

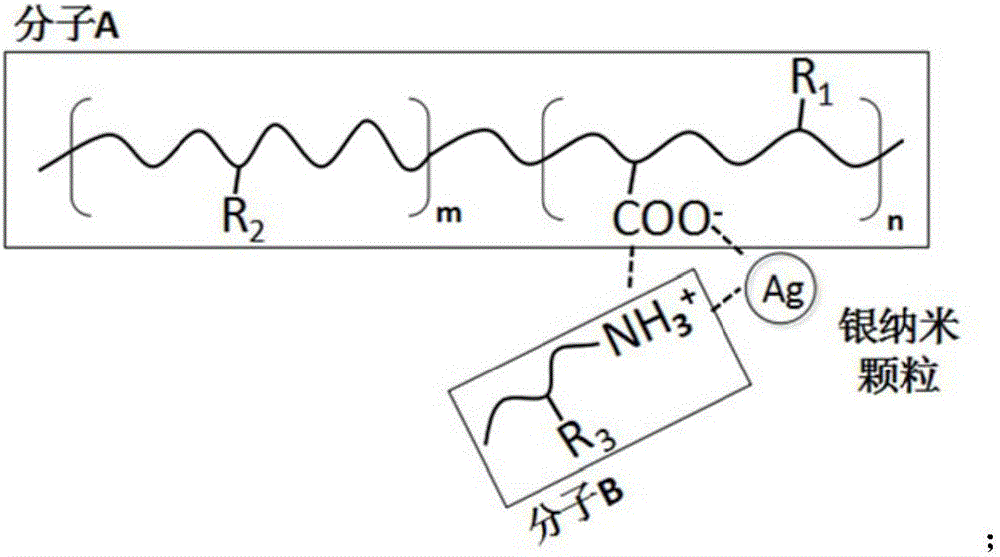

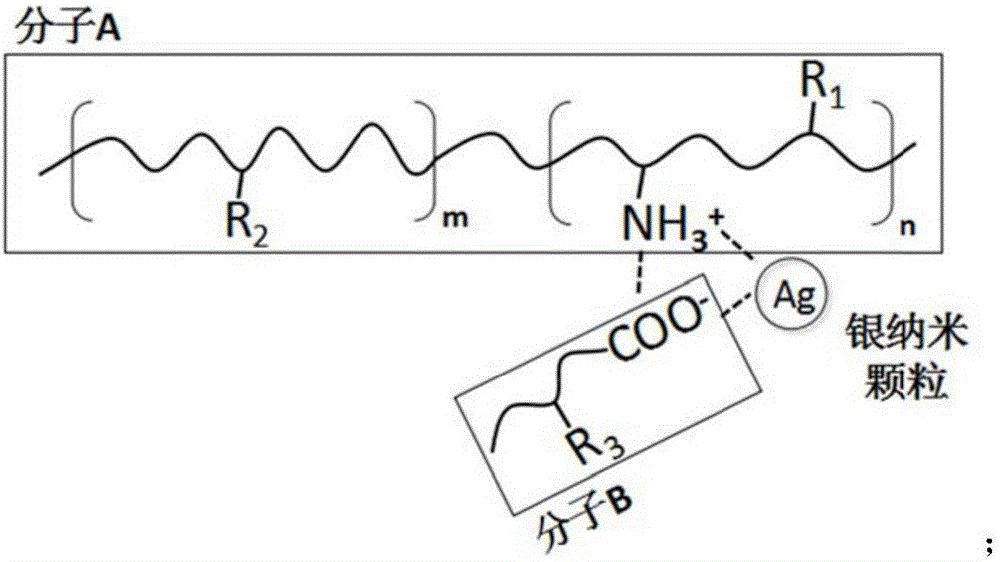

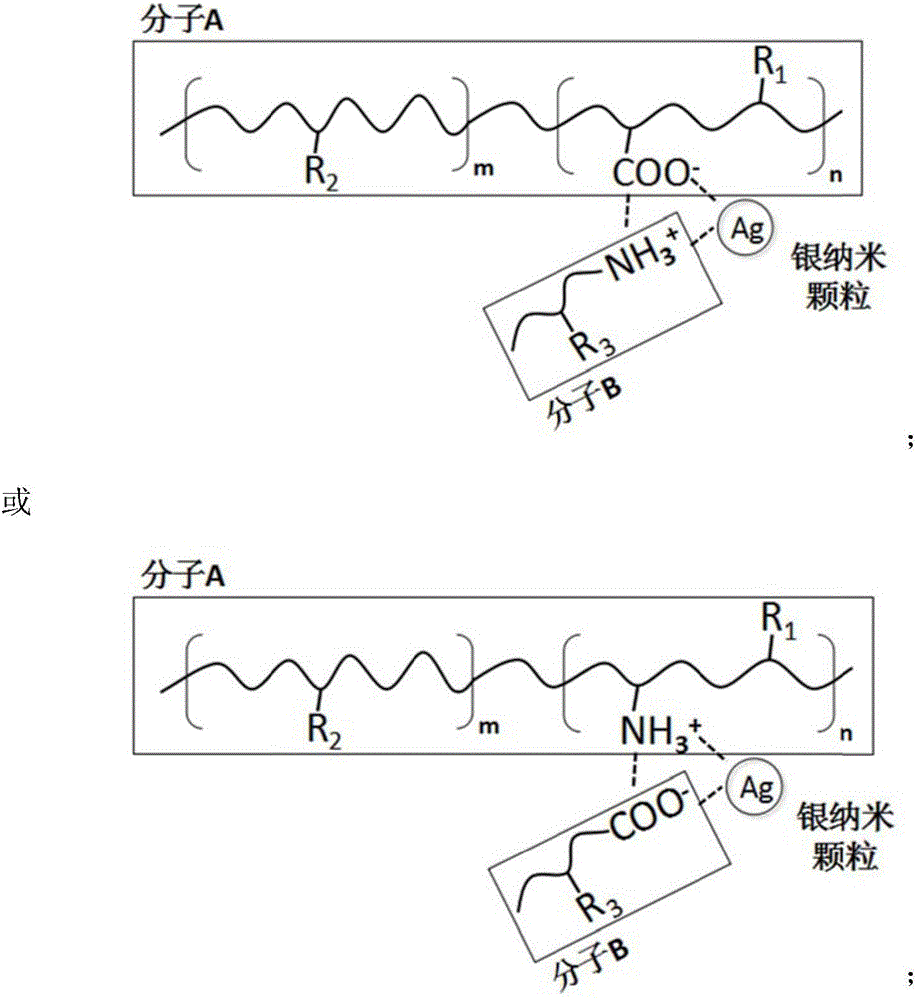

Method used

Image

Examples

Embodiment 1

[0058] A kind of preparation method of antibacterial antistatic polyacrylonitrile fiber, under the condition of 20 ℃, the chitosan aqueous solution containing the amino group with the mass percent concentration of 0.5% and the n-butyric acid aqueous solution containing the carboxyl group with the mass percent concentration of 3% are pressed Mixing, wherein, the relative molecular weight of chitosan is 240000, the molecular weight of n-butyric acid is 88.1, the molar ratio of chitosan and n-butyric acid is 1:0.3, accompanied by stirring; adopt 0.1mol / L HCl solution to adjust the reaction system pH value to 4, and then dropwise added AgNO with a concentration of 0.005g / mL to the mixture 3 solution, where AgNO 3 The molar ratio to chitosan was 0.1:1, and the stirring was continued for 0.5h after the dropwise addition was completed; 3 The molar ratio with sodium borohydride is 1:0.5, continue stirring for 1h after the dropwise addition, to obtain an aqueous solution of nano-silve...

Embodiment 2

[0062] A kind of preparation method of antibacterial antistatic polyacrylonitrile fiber, under the condition of 60 ℃, the carboxymethyl chitosan aqueous solution containing amino group with the concentration of 3% by mass percentage and the n-amyl chitosan containing carboxyl group with the concentration of 10% by mass are mixed Acid aqueous solution mixing, wherein, the relative molecular weight of carboxymethyl chitosan is 10000, the molecular weight of n-valeric acid is 102.13, the molar ratio of carboxymethyl chitosan and n-valeric acid is 1:1, accompanied by stirring; adopt 0.15 mol / L of H 2 SO 4 The solution adjusts the pH value of the reaction system to 6, and then drips a silver acetate solution with a concentration of 2g / mL in the mixed solution, wherein the molar ratio of silver acetate to carboxymethyl chitosan is 10:1, and after the addition is completed, continue Stir for 1h; add dropwise a concentration of 0.1g / mL potassium borohydride aqueous solution, wherein ...

Embodiment 3

[0066] A preparation method of antibacterial and antistatic polyacrylonitrile fiber, under the condition of 30 DEG C, mixing an aqueous solution of polyacrylamide containing amino groups with a mass percent concentration of 1% and a carboxyl-containing n-hexanoic acid aqueous solution with a mass percent concentration of 4%, Among them, the relative molecular weight of polyacrylamide is 1,000,000, the molecular weight of n-caproic acid is 115.15, the molar ratio of polyacrylamide and n-caproic acid is 1:0.4, accompanied by stirring; 0.3mol / L HNO 3 The solution adjusted the pH value of the reaction system to 5, and then added dropwise a silver sulfate solution with a concentration of 0.008g / mL to the mixed solution, wherein the molar ratio of silver sulfate to polyacrylamide was 0.5:1, and continued to stir for 0.6 h; dropwise adding concentration is 0.02g / mL ascorbic acid aqueous solution, wherein the mol ratio of silver sulfate and ascorbic acid is 1:0.8, continue to stir 1.1h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com