Preparation method of dialkylphenol polyamine emulsifier, preparation of emulsified asphalt and application thereof

A technology of dialkylphenol polyamines and emulsifiers, which is applied in the field of preparation of emulsified asphalt and dialkylphenol polyamine emulsifiers. and other problems, to achieve the effect of large-scale popularization and application, good emulsification performance and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

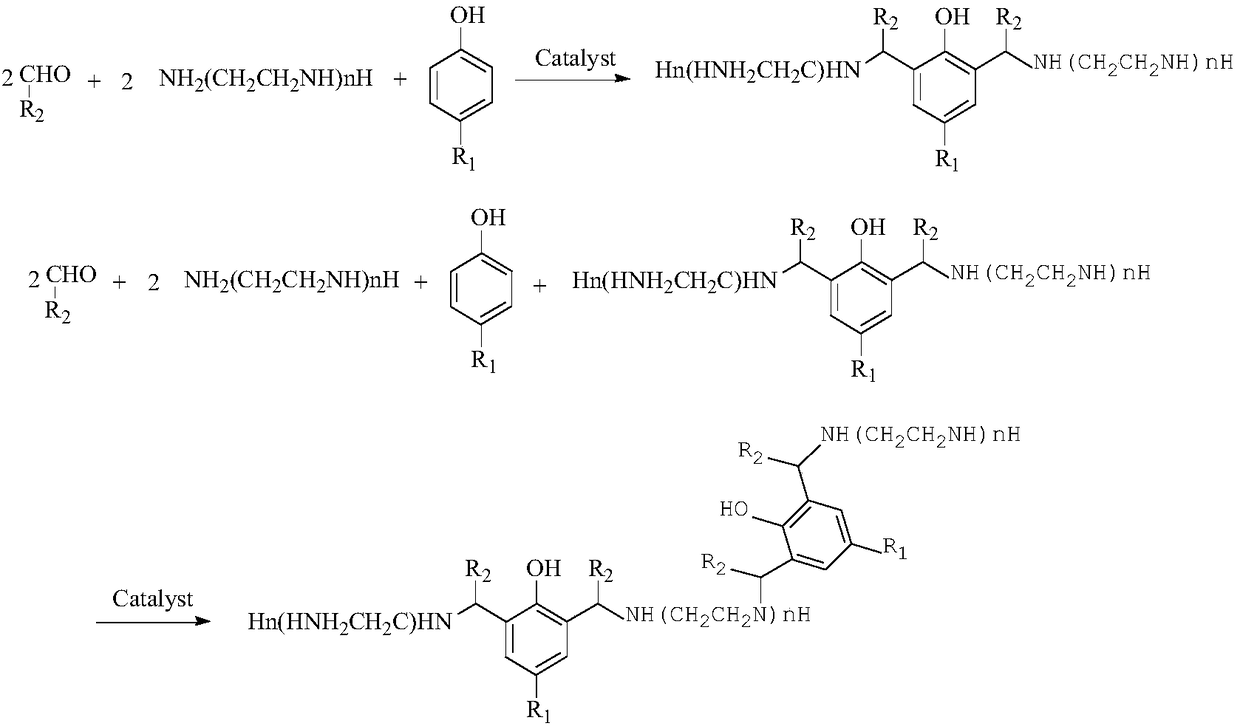

[0047] Preparation of double alkylphenol polyamine emulsifier of the present invention:

[0048](1) Add 20.6g (0.1mol) of octylphenol, 20.26g (0.2mol) of diethylenetriamine, 50ml of absolute ethanol, and 0.21g of 2-ethylimidazole into the reactor, raise the temperature to 80°C, and drop 37%~40% 16.6g (0.2mol) formaldehyde solution, add dropwise completely within 30-40 minutes, react for 4.5h after dropwise to obtain the intermediate.

[0049] (2) Cool the intermediate to 25°C, add 20.6g (0.1mol) of octylphenol and 10.13g (0.1mol) of diethylenetriamine, raise the temperature to 85°C, and then dropwise add a concentration of 37% to the reaction flask ~40% formaldehyde solution 16.6g (0.2mol), drop in 30-40 minutes, react 6h after dropping completely, ethanol is distilled off under reduced pressure, obtains yellow viscous liquid, detects through liquid chromatography and calculates yield to be 83.7%, reserved for experimentation.

[0050] The molecular weight of the final produ...

Embodiment 2

[0058] Preparation of double alkylphenol polyamine emulsifier of the present invention:

[0059] (1) Add 26.2g (0.1mol) of dodecanol, 32.19g (0.22mol) of triethylenetetramine, 50ml of water, and 0.69g of 1-phenylethylimidazole into the reactor, raise the temperature to 95°C, and drop the concentration Add 18.26g (0.22mol) of 37%-40% formaldehyde solution dropwise within 30-40 minutes, and react for 4.5h after the dropwise addition to obtain the intermediate.

[0060] (2) Cool the intermediate to 25°C, add 26.2g (0.1mol) of dodecylphenol and 17.55g (0.15mol) of triethylenetetramine, raise the temperature to 100°C, and then dropwise add 37% to 40 % 18.26g (0.22mol) formaldehyde solution, dripped within 30-40 minutes, reacted for 4h after the dropwise addition was complete, and distilled water under reduced pressure to obtain a yellow viscous liquid. The calculated yield was 79.6% through liquid chromatography. for experiments.

[0061] The molecular weight of the final product...

Embodiment 3

[0069] Preparation of double alkylphenol polyamine emulsifier of the present invention:

[0070] (1) Add 22g (0.1mol) of nonylphenol, 32.08g (0.22mol) of triethylenetetramine, 50ml of n-hexane, and 1.1g of sulfomethylimidazole into the reactor, raise the temperature to 80°C, and dropwise add a concentration of 37 17.85 g (0.215 mol) of formaldehyde solution of %-40% was added dropwise within 30-40 minutes, and the intermediate was obtained by reacting for 8 hours after the drop was completed.

[0071] (2) Cool the intermediate to 25°C, add 23.4g (0.1mol) of decylphenol and 14.63g (0.15mol) of tetraethylenepentamine, raise the temperature to 95°C, then add dropwise 17.02g (0.205 mol) 37%~40% (0.215mol) formaldehyde solution, drop in 30-40 minutes, react 5h after dropping completely, distill off n-hexane, obtain yellow viscous liquid, detect and calculate yield through liquid chromatography is 92.6%, reserved for experimentation.

[0072] The molecular weight of the final prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com