Stain-resistant and mildew-resistant diatom mud coating and preparation method thereof

A diatom mud coating, stain-resistant technology, applied in fire-resistant coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

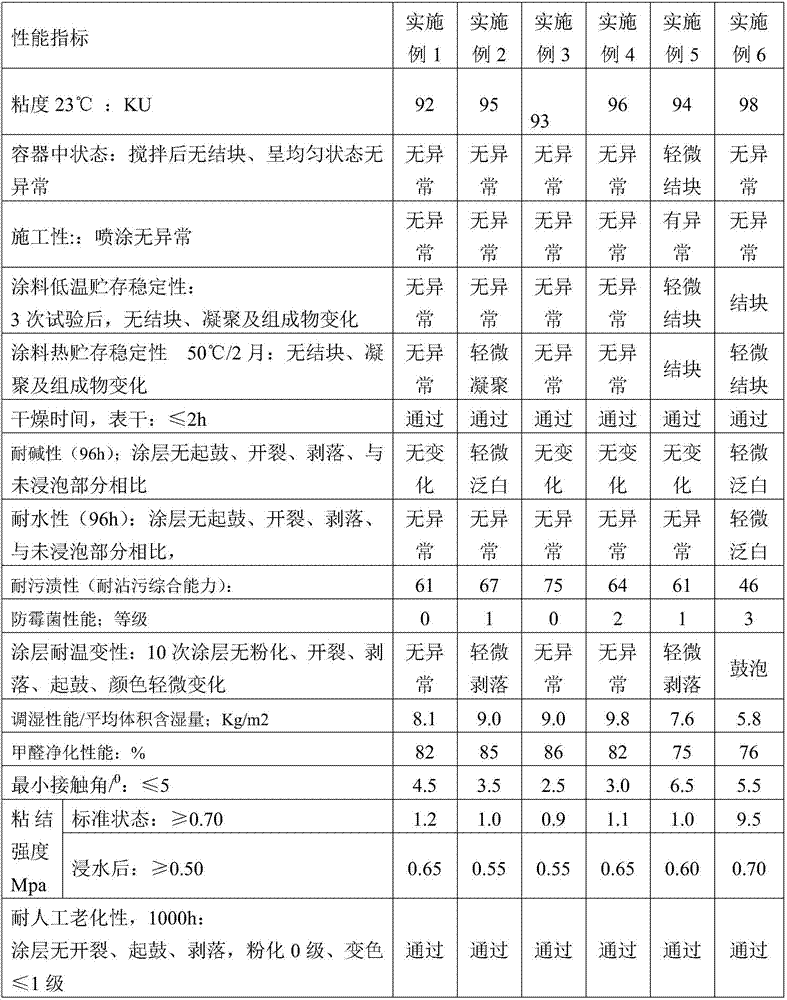

Examples

Embodiment 1

[0020] In a stainless steel dispersing pot equipped with a high-speed disperser, add 25 parts of deionized water, 0.6 parts of anionic polycarboxylate ammonium salt, and 0.1 parts of C12-14 fatty alcohol polyoxyethylene ether in sequence at a stirring speed of 350 rpm. 2 parts, 2 parts of propylene glycol, 0.5 parts of AMP-95 multifunctional agent, 0.3 parts of defoamer, 0.3 parts of BIT isothiazolinone, 0.1 part of methyl-1H-benzimidazol-2-yl-carbamate, 3 - 0.2 parts of iodine-2-propynyl-butyl carbamate, 6.5 parts of titanium dioxide, 7.5 parts of kaolin, 15 parts of diatomaceous earth, 11.2 parts of zeolite powder, 1 part of diatomite composite nano-zinc oxide, stir well Afterwards, disperse at a speed of 1200 rpm until the fineness is less than 60 microns, add 28 parts of silicone-modified styrene-acrylic emulsion, 2,2,4-trimethyl-1,3-pentanediol mono Stir 0.7 parts of isobutyrate evenly, and finally add 0.2 parts of AMP-95 multifunctional agent and 0.8 parts of thickening ...

Embodiment 2

[0022] In a stainless steel dispersing pot equipped with a high-speed disperser, add 27 parts of deionized water, 0.6 parts of anionic polycarboxylate ammonium salt, and 0.1 parts of C12-14 fatty alcohol polyoxyethylene ether in sequence at a stirring speed of 400 rpm. 2 parts, 2 parts of propylene glycol, 0.5 parts of AMP-95 multifunctional agent, 0.3 parts of defoamer, 0.3 parts of BIT isothiazolinone, 0.1 part of methyl-1H-benzimidazol-2-yl-carbamate, 3 - 0.2 parts of iodine-2-propynyl-butyl carbamate, 5.8 parts of titanium dioxide, 9.5 parts of kaolin, 12 parts of diatomaceous earth, 11.2 parts of zeolite powder, 1 part of diatomite composite nano zinc oxide, stir well Afterwards, disperse at a speed of 1200 rpm until the fineness is less than 60 microns, add 28 parts of styrene-acrylic emulsion and 0.7 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate in sequence 0.2 parts of AMP-95 multifunctional agent and 0.5 parts of thickening and leveling agent were added at ...

Embodiment 3

[0024] In a stainless steel dispersing pot equipped with a high-speed disperser, add 26 parts of deionized water, 0.6 parts of anionic polycarboxylate ammonium salt, and 0.1 parts of C12-14 fatty alcohol polyoxyethylene ether in sequence at a stirring speed of 450 rpm. 2 parts, 2 parts of propylene glycol, 0.5 parts of AMP-95 multifunctional agent, 0.3 parts of defoamer, 0.3 parts of BIT isothiazolinone, 0.1 part of methyl-1H-benzimidazol-2-yl-carbamate, 3 - 0.2 parts of iodine-2-propynyl-butyl carbamate, 6.5 parts of titanium dioxide, 7.5 parts of kaolin, 21 parts of diatomaceous earth, 6.2 parts of zeolite powder, 1.1 parts of diatomite composite nano-zinc oxide, stir well Afterwards, disperse at a speed of 1200 rpm until the fineness is less than 60 microns, add 26 parts of silicone-modified styrene-acrylic emulsion, 2,2,4-trimethyl-1,3-pentanediol mono Stir 0.7 parts of isobutyrate evenly, and finally add 0.2 parts of AMP-95 multifunctional agent and 0.7 parts of thickenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com