Method for aluminum cladding of positive electrode material by wet method, positive electrode material, positive electrode and battery

A positive electrode material, wet coating technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of low electronic conductivity, material structure collapse, poor cycle performance, etc., to achieve high safety performance and wide application range , good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In terms of mass ratio, the aluminum-containing compound: nickel-cobalt-manganese ternary positive electrode material: dispersant: alkaline additive is 1:71:143:5.

[0044] Follow the steps below to coat the cathode material with aluminum:

[0045] Weigh 2.8g of aluminum nitrate and disperse it in 200mL of deionized water, stir evenly, and heat. When the temperature rises to 90°C, measure 15mL of ammonia solution (density 0.88g / mL), and divide it into 5 parts, each 3mL, Add ammonia water to the aluminum nitrate aqueous solution in 5 times, the time interval between each addition is 0.15h, and after the addition is completed, react at a constant temperature of 90°C for 2h to obtain an aluminum-containing intermediate solution for use;

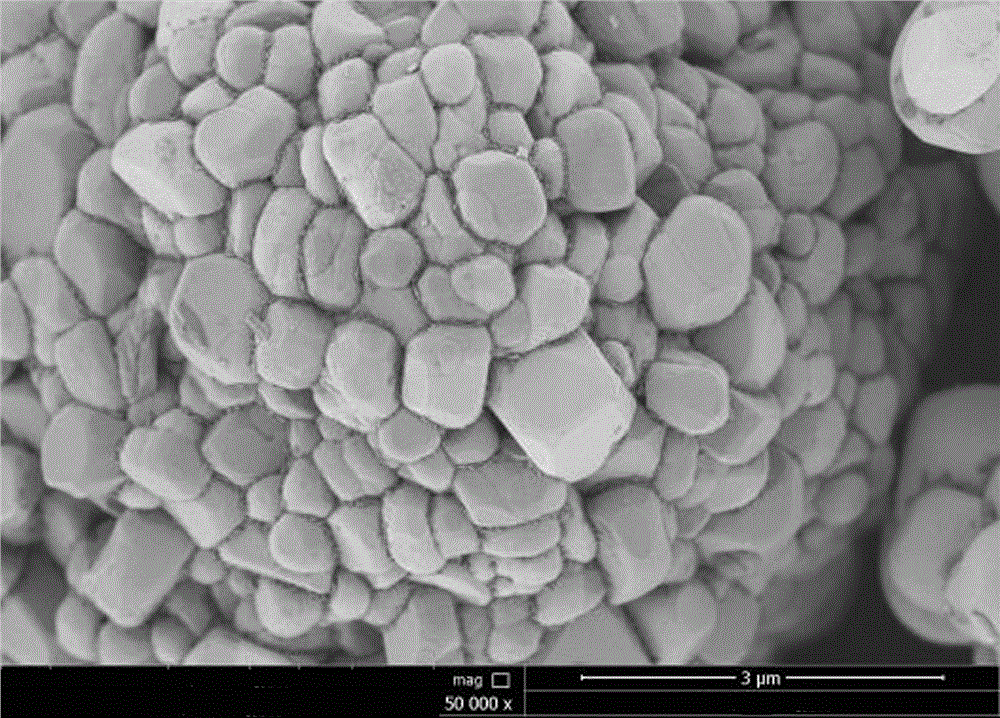

[0046] Then weigh 200g of structural formula as LiNi 0.5 co 0.2 mn 0.3 o 2 Disperse the positive electrode material (secondary particles) in 200mL deionized water, cool down to 60°C, gradually add the prepared aluminum-containing inte...

Embodiment 2

[0050]In terms of mass ratio, the aluminum-containing compound: nickel-cobalt-manganese ternary positive electrode material: dispersant: alkaline additive is 1:71:143:7.

[0051] Follow the steps below to coat the cathode material with aluminum:

[0052] Weigh 2.8g of aluminum nitrate and disperse it in 200mL of deionized water, stir evenly, and heat. When the temperature rises to 90°C, measure 20g of ammonium bicarbonate solution (concentration: 1mol / L), and divide it into 5 parts, each 4g , add the ammonium bicarbonate solution to the aluminum nitrate aqueous solution in 5 times, the time interval between each addition is 0.25h, after the addition is completed, react at a constant temperature at 90°C for 2h, and obtain an aluminum-containing intermediate solution for use;

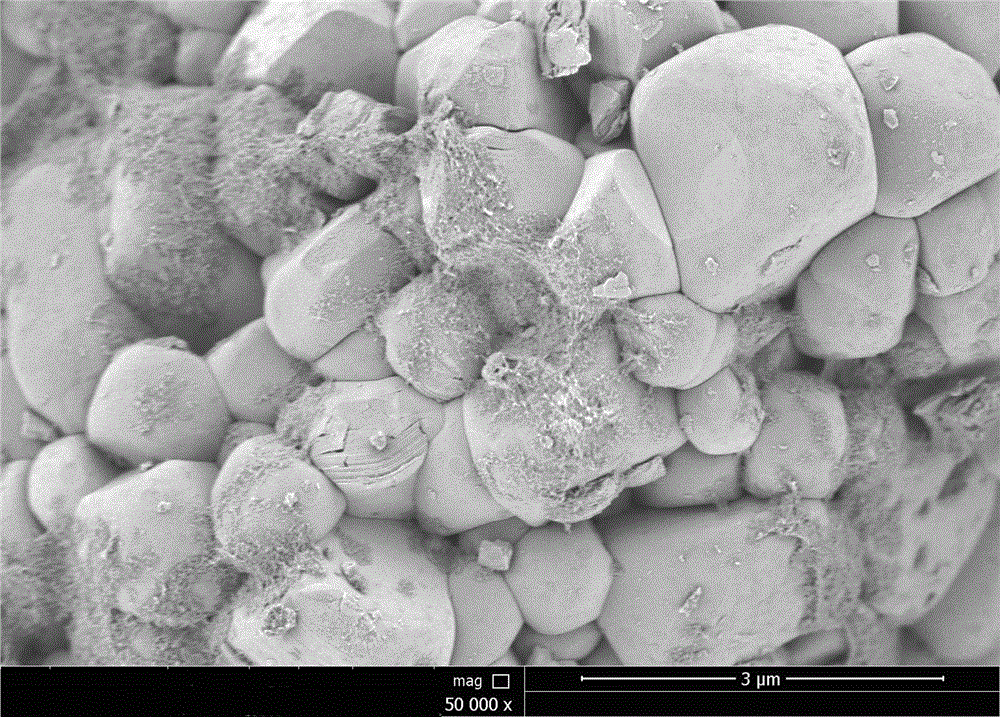

[0053] Then weigh 200g of structural formula as LiNi 0.5 co 0.2 mn 0.3 o 2 Disperse the positive electrode material (secondary particles) in 200mL deionized water, cool down to 60°C, gradually add the...

Embodiment 3

[0070] In terms of mass ratio, the aluminum-containing compound: nickel-cobalt-manganese ternary positive electrode material: dispersant: alkaline additive is 1:50:100:5.

[0071] Follow the steps below to coat the cathode material with aluminum:

[0072] Weigh 4g of aluminum sulfate and disperse it in 200mL of deionized water, stir evenly, and heat. When the temperature rises to 75°C, measure 24mL of ammonia solution (density 0.88g / mL), and divide it into 8 parts, each 3mL, divide Add ammonia water to the aluminum sulfate aqueous solution 8 times, the time interval between each addition is 0.3h, after the addition is completed, react at a constant temperature of 75°C for 3h, and obtain an aluminum-containing intermediate solution for use;

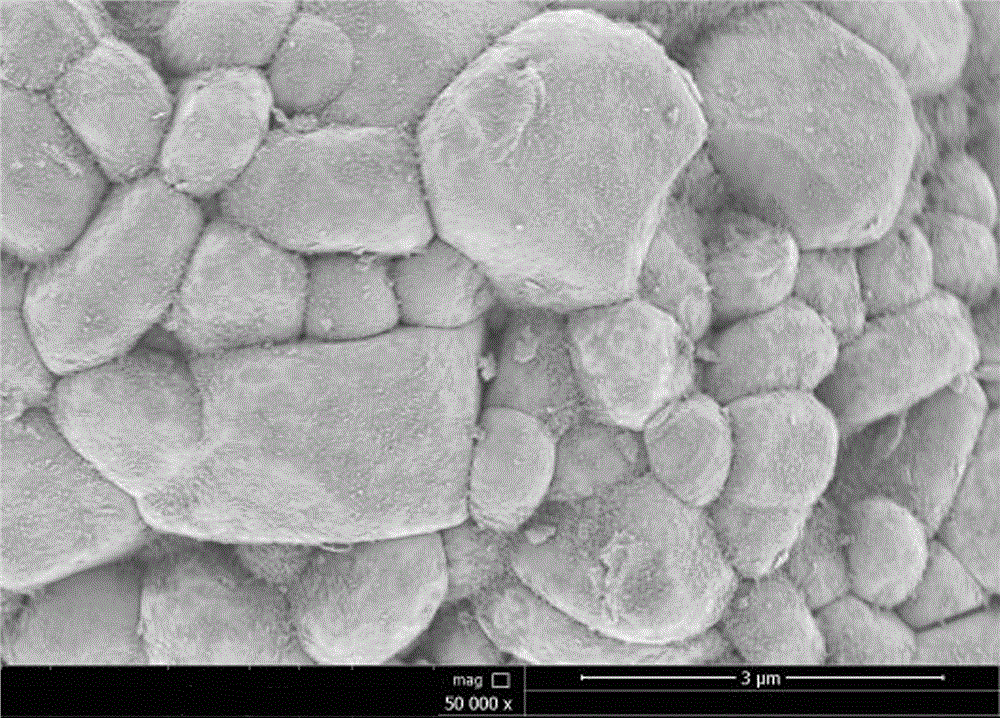

[0073] Then weigh 200g of structural formula as LiNi 0.5 co 0.25 mn 0.25 o 2 Disperse the positive electrode material (like single crystal) in 200mL deionized water, cool down to 50°C, gradually add the prepared aluminum-containing int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com