Composite electrode for medium and low temperature proton conductor solid oxide cell and preparation

A solid oxide, proton conductor technology, used in battery electrodes, circuits, electrical components, etc., can solve the problems of large catalyst surface, poor activity, reduced activity, etc., to achieve high catalytic activity, low operating temperature, high heat and chemical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

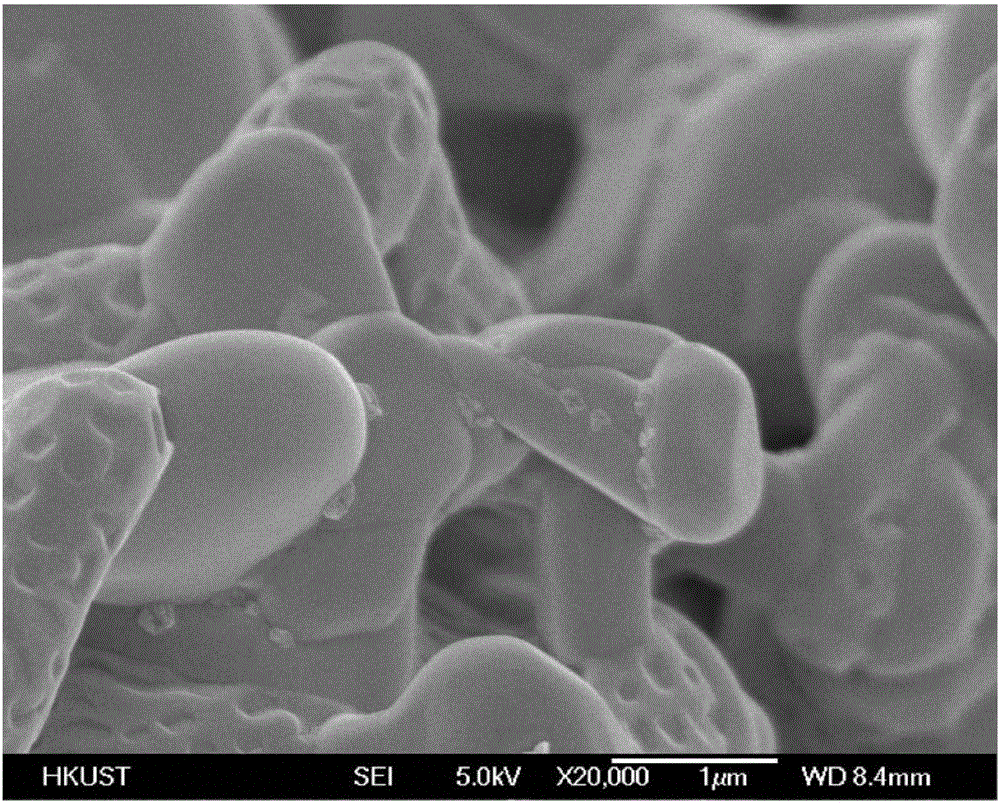

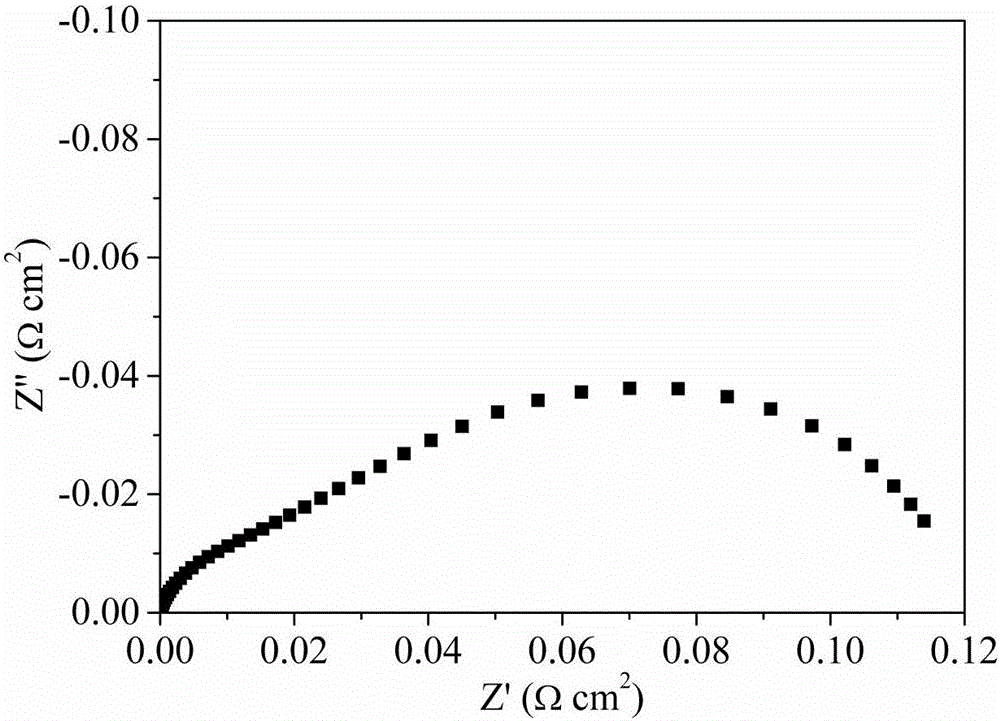

[0027] Using high-purity BaCO 3 , CeO 2 、Ni 2 o 3 and Y 2 o 3 Powder (analytically pure), according to the chemical formula Ba 0.9 Ni 0.1 (Ce 0.8 Y 0.2 ) 0.9 o 3-δ The stoichiometric ratio was weighed and the ingredients were weighed; then it was wet-milled for 5 hours in a ball mill tank with absolute ethanol as a medium, dried, and roasted for 10 hours in an air atmosphere at 1200°C; the prepared powder was placed in a ball mill tank Using absolute ethanol as the medium, wet grinding for 2 hours, mixing evenly, drying, adding 15% carbon (mass ratio), and then pressing to obtain a green body; finally, the green body was sintered at 1250 ° C for 10 hours to obtain a porous Ba 0.9 Ni 0.1 (Ce 0.8 Y 0.2 ) 0.9 o 3-δ materials (such as figure 1 shown). Porous Ba 0.9 Ni 0.1 (Ce 0.8 Y 0.2 ) 0.9 o 3-δ material at 800°C and 5% H 2 / Ar under high-temperature reduction to obtain Ni nanoparticles and BaCe 0.8 Y 0.2 o 3-δ Composite electrodes composed of proton c...

Embodiment 2

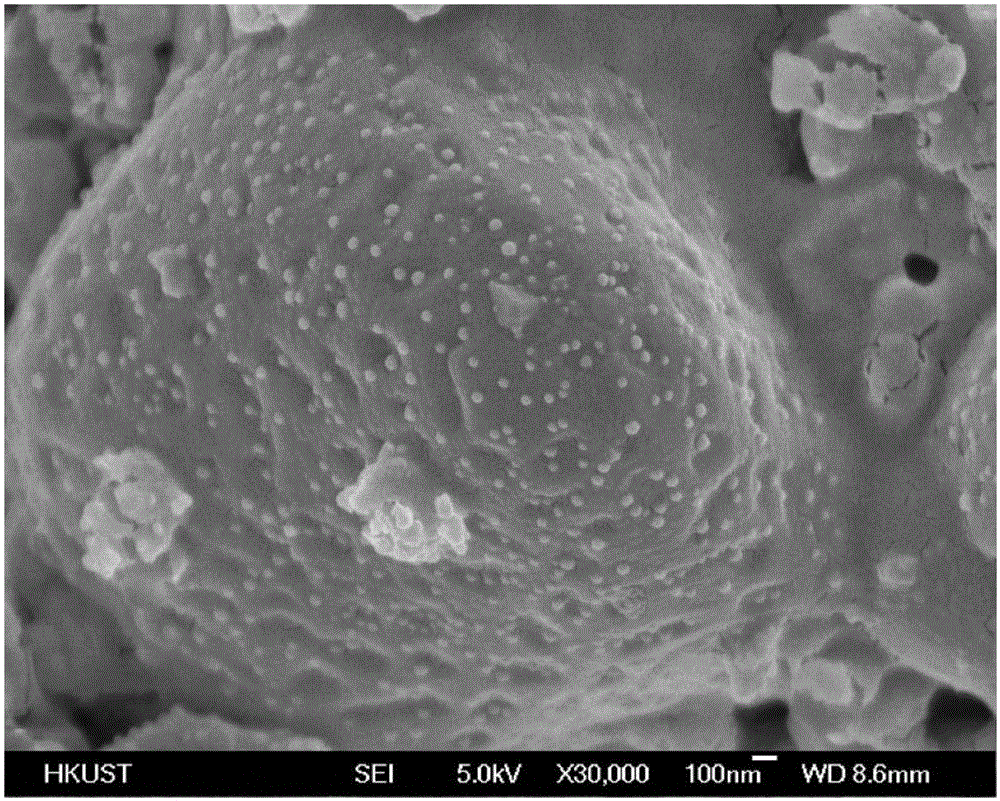

[0029] Porous Ba 0.9 Ni 0.1 (Ce 0.8 Y 0.2 ) 0.9 o 3-δ material at 900°C and 5% H 2 / Ar under high-temperature reduction to obtain Ni nanoparticles and BaCe 0.8 Y 0.2 o 3-δ Composite electrodes composed of proton conductors (such as figure 2 shown). All the other steps are the same as in Example 1.

Embodiment 3

[0031] Porous Ba 0.9 Ni 0.1 (Ce 0.8 Y 0.2 ) 0.9 o 3-δMaterial at 1000°C and 5%H 2 / Ar under high-temperature reduction, and finally obtained Ni nanoparticles and BaCe 0.8 Y 0.2 o 3-δ Composite electrodes composed of proton conductors. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com