Positive electrode material for metal-air battery and preparation method for positive electrode

A metal-air battery and cathode material technology, applied in the field of electrochemical energy, can solve the problems of long-term battery storage difficulties, complex manufacturing process, low current density, etc., achieve wide applicability, prolong battery life, and reduce battery overpotential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: (coating method)

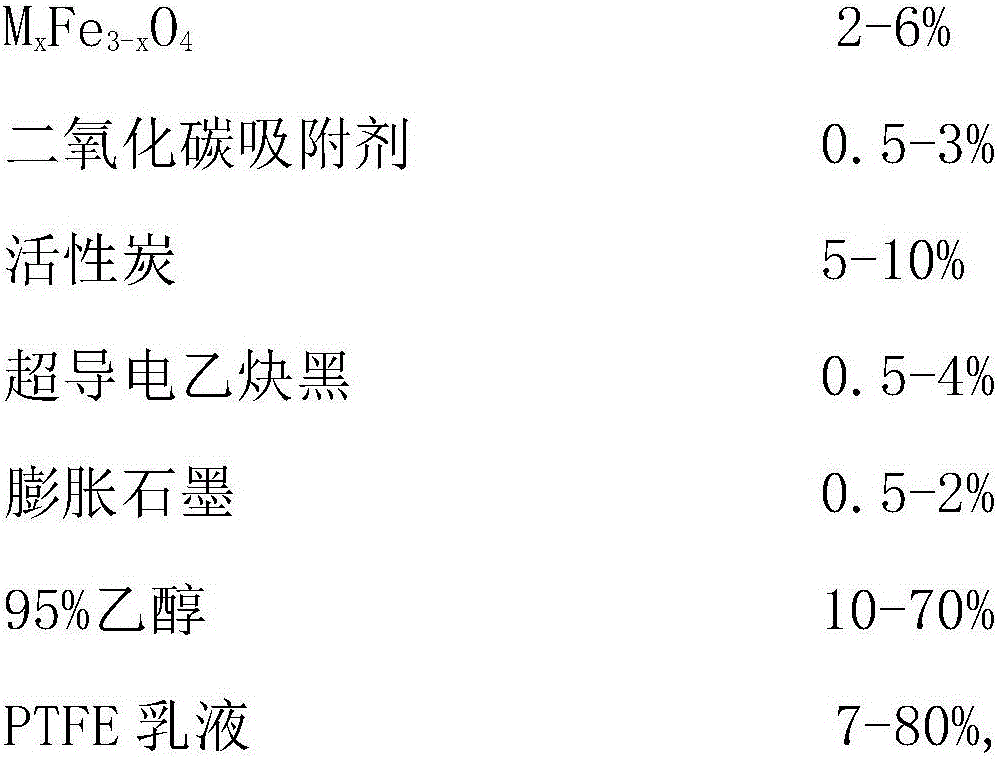

[0035] Positive electrode material formula:

[0036]

[0037] Prepare the positive electrode of embodiment 1 by coating method:

[0038] Add other components other than PTFE floating liquid into 95% ethanol, after the solids are fully wetted, stir evenly, ultrasonically disperse for 45-60min to disperse evenly; then slowly add PTFE emulsion dropwise under stirring state, stir evenly at 1000rpm to form Viscous colloid, press filtration to remove excess liquid, and obtain a mixture with a viscosity suitable for coating; spread the mixture on a nickel mesh with a thickness of 2.5mm, and then place it on a waterproof and breathable membrane with a waterproof grade of IP 68, at 120°C Dry for 9 hours, cool to room temperature, add hydrophilic non-woven fabric and microfiltration membrane, at room temperature at 50Kg / cm 2 Use a flat plate to press for 3-5 minutes under a certain pressure, so that the thickness of the positive electrode is ...

Embodiment 2

[0039] Embodiment 2: (dipping method)

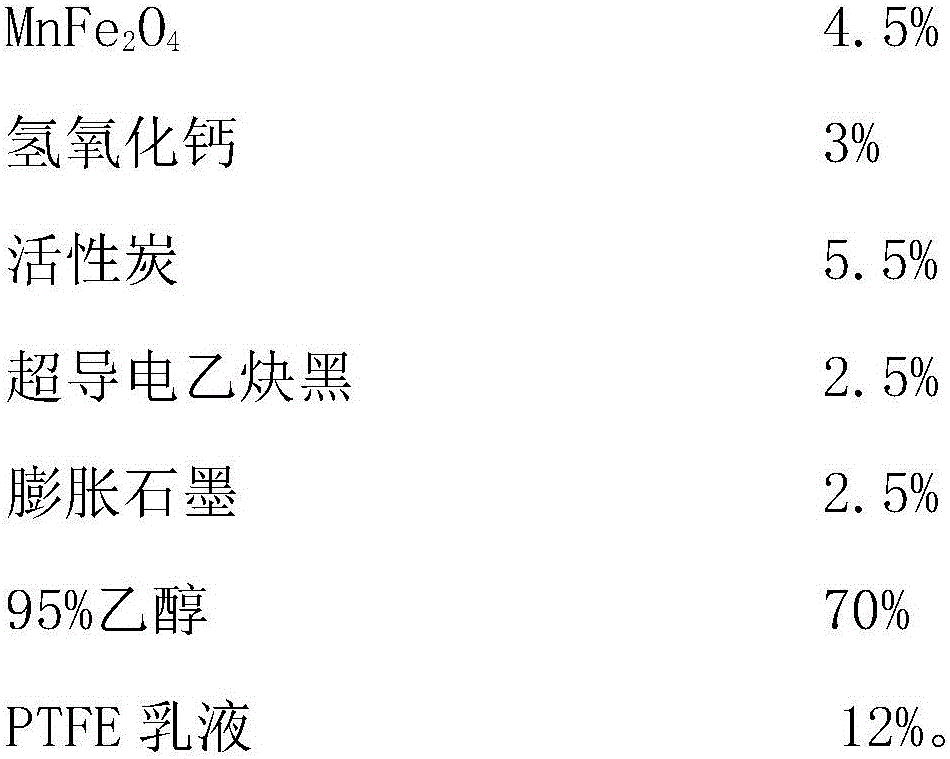

[0040] Positive electrode material formula:

[0041]

[0042] The positive electrode of embodiment 2 is prepared by dip-coating method:

[0043] Add 95% ethanol to other components other than PTFE floating liquid, and stir evenly after the solids are fully wet; then slowly add PTFE emulsion dropwise under stirring, and stir evenly at a speed of 1000rpm to form a viscous slurry to adjust the viscosity to a viscosity suitable for dip coating; dip a nickel mesh with a thickness of 2.5mm into the above slurry, take it out after 10s, and then place it on a waterproof and breathable membrane with a waterproof grade of IP 68, dry it in vacuum at 140°C for 7 hours, add pro- Water non-woven fabric and microfiltration membrane, at room temperature at 80Kg / cm 2 Under a certain pressure, use a flat plate to press for 3-5 minutes until the thickness of the positive electrode sheet is 1.0-1.5mm, and the positive electrode of the battery is obtain...

Embodiment 3

[0044] Embodiment 3: (rolling method)

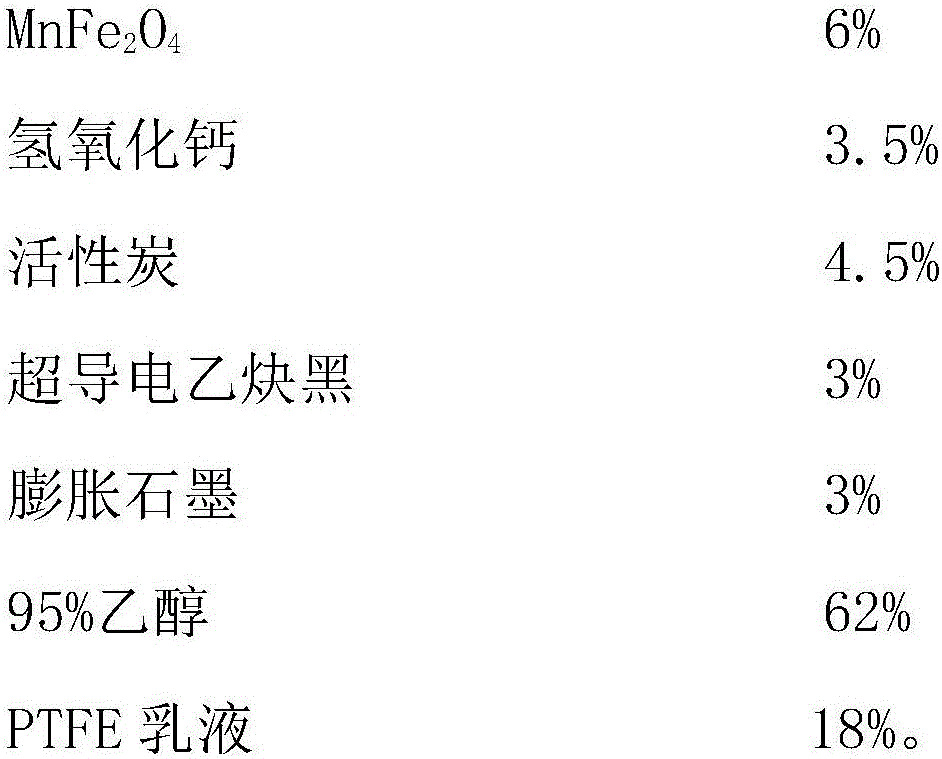

[0045] Positive electrode material formula:

[0046]

[0047]

[0048] The positive pole of embodiment 3 is prepared by rolling method:

[0049]Add 95% ethanol to other components other than the PTFE floating liquid. After the solids are fully wetted, stir evenly and then add the PTFE emulsion. After stirring at 400rpm to form a ball, roll it into a sheet with a thickness of 0.5-2mm to obtain A battery catalyst layer sheet with a uniform thickness; spread the sheet on a nickel mesh with a thickness of 2.5mm, roll it into 0.8-1.0mm, add a waterproof breathable membrane with a waterproof grade of IP 68, a hydrophilic non-woven fabric and a microfiltration membrane, Roll it to a thickness of 1-1.5 mm, dry at 150°C for 4 hours, and cool to room temperature to obtain the positive electrode of the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com