Method for achieving aerosol cultivation and suspension tuber formation of Chinese yams

A technology of aerosol cultivation and tuber formation, which is applied in the field of yam aerosol cultivation and suspended tuber formation, which can solve the problems of difficulty in ensuring product appearance or quality, insufficient yield, high labor intensity, etc., and reduce the use of pesticides and labor intensity. The effect of low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

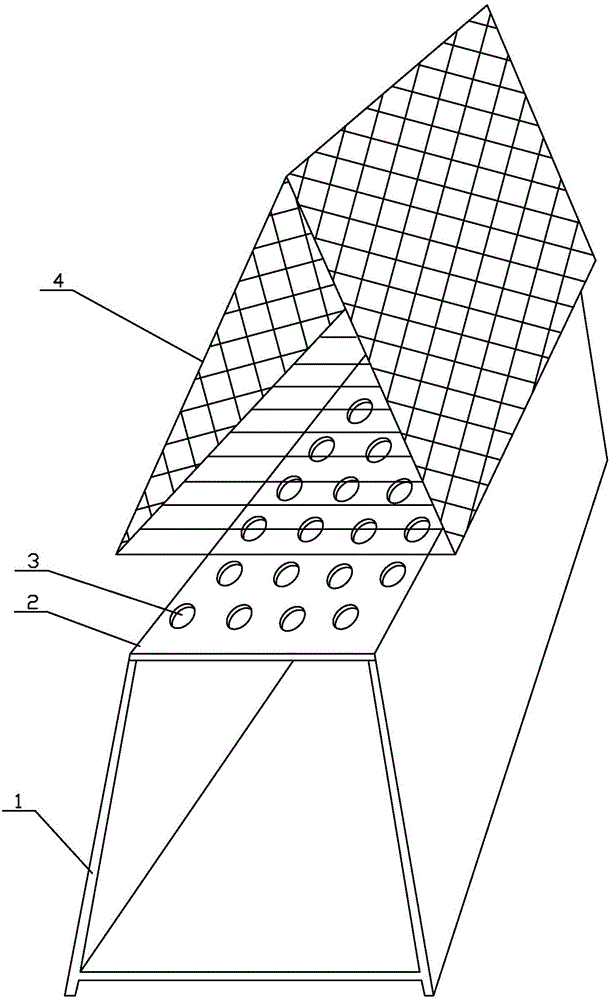

[0037] Embodiment 1: The cultivation device used in the suspended tuber forming method of Chinese yam aerosol cultivation of the present invention

[0038] figure 1 The cultivation device used for the suspended tuber forming method of Chinese yam aerosol cultivation of the present invention includes a three-dimensional planting bed 1 whose longitudinal section is trapezoidal (also can be square or columnar), and the internal space of the three-dimensional planting bed 1 is for Chinese yam tuber ( That is, for Chinese yam to grow rhizomes), in the inner space, there are several nozzles that supply the ACM microbial nutrient solution to the Chinese yam rhizomes in aerosol form, and these nozzles communicate with the outlet of the high-pressure pump through pipelines, and the inlet of the high-pressure pump The pipeline communicates with the container for storing the ACM microbial nutrient solution; the upper end surface of the three-dimensional planting bed 1 is laid with a plan...

Embodiment 2

[0040] Embodiment 2: the preparation of ACM microbial nutrient solution

[0041] 1) Weigh an appropriate amount of potassium sulfate, ammonium dihydrogen phosphate, magnesium sulfate heptahydrate, sodium ferric edetate, boric acid, anhydrous manganese chloride, zinc sulfate heptahydrate, copper sulfate pentahydrate, sodium molybdate, sugar The substance and water are mixed into a solution, and the concentration of each component in the obtained solution is controlled as follows: Potassium sulfate 405g / L, ammonium dihydrogen phosphate 58g / L, magnesium sulfate heptahydrate 123g / L, sodium ferric edetate 17g / L L, boric acid 12g / L, anhydrous manganese chloride 0.72g / L, zinc sulfate heptahydrate 0.09g / L, copper sulfate pentahydrate 0.03g / L, sodium molybdate 0.013g / L, carbohydrates 2000g / L ( Wherein sucrose 1000g / L, glucose 500g / L, honey 500g / L), obtain nutrient base;

[0042] 2) Add 650g rhizobia, 550g nitrogen-fixing bacteria, 480g carbon bacteria, 600g photosynthetic bacteria, 55...

Embodiment 3

[0043] Embodiment 3: the preparation of ACM microbial nutrient solution

[0044] 1) Weigh an appropriate amount of potassium sulfate, ammonium dihydrogen phosphate, magnesium sulfate heptahydrate, sodium ferric edetate, boric acid, anhydrous manganese chloride, zinc sulfate heptahydrate, copper sulfate pentahydrate, sodium molybdate, sugar Substances and water are prepared into a solution, and the concentration of each component in the obtained solution is controlled as follows: Potassium sulfate 410g / L, ammonium dihydrogen phosphate 50g / L, magnesium sulfate heptahydrate 120g / L, sodium ferric edetate 20g / L L, boric acid 10g / L, anhydrous manganese chloride 0.7g / L, zinc sulfate heptahydrate 0.08g / L, copper sulfate pentahydrate 0.04g / L, sodium molybdate 0.02g / L, carbohydrates 2100g / L ( Wherein sucrose 1000g / L, glucose 500g / L, honey 600g / L), obtain nutrient base;

[0045] 2) Add 600g rhizobia, 600g nitrogen-fixing bacteria, 400g carbon bacteria, 550g photosynthetic bacteria, 600g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com