Device and method for electrochemically treating sewage with microorganisms and microbial film culture method

A microbial electrochemical and microbial membrane technology, applied in the field of microbial membrane cultivation, can solve the problems of affecting nitrification reaction speed, increasing power consumption and operating costs, and long hydraulic retention time, so as to reduce sewage treatment costs and reduce sludge production , The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

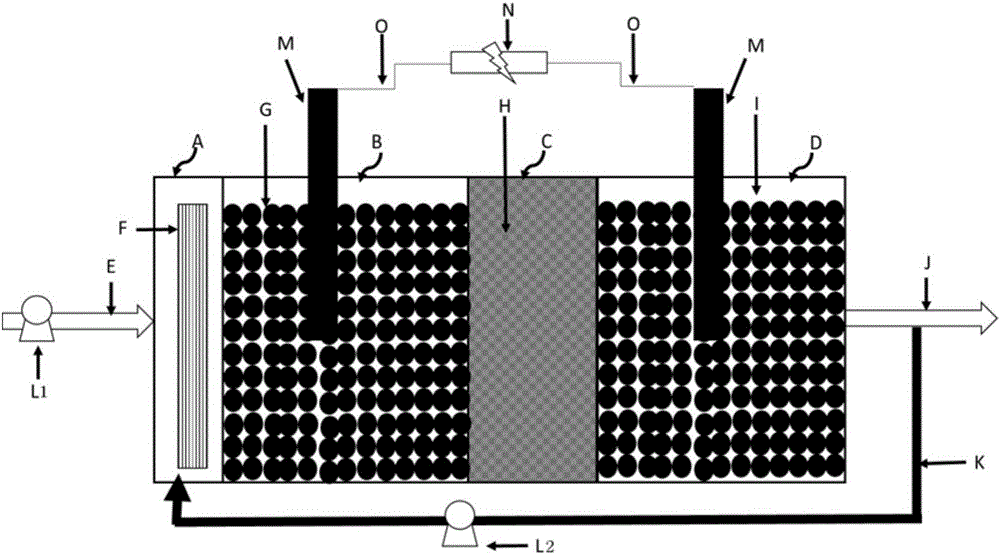

[0044] like figure 1 As shown, the device provided by the present invention utilizing microbial electrochemical treatment of sewage comprises: grid and grit chamber A, aerobic electrode chamber B, isolation pond C, anoxic / anaerobic electrode chamber D, aerobic electrode chamber B and The bottom of the isolation tank C is connected to each other, the water inlet of the anoxic / anaerobic electrode chamber D is provided with a baffle (not shown in the figure), the water outlet of the anoxic / anaerobic electrode chamber D is connected to the drain pipe J, and the anoxic / anaerobic electrode chamber D is connected to the drain pipe J. The water outlet of the anaerobic electrode chamber D is also connected to the grid and the grit chamber A through the pressure water pump (reflux pump) L2 and the return pipe K. The aerobic electrode chamber is an open-top reactor filled with inert porous conductive materials, which can be filled with graphite particles, activated carbon, graphite sheet...

Embodiment 2

[0047] Before the sewage treatment, the enrichment culture of the microbial film is carried out by using the device for electrochemically treating sewage provided by the invention.

[0048] The first is the load of activated sludge in the aerobic electrode chamber and the anoxic / anaerobic electrode chamber: add an inert porous conductive material G in the aerobic electrode chamber (the top is not closed), and add an inert porous conductive material G in the anoxic / anaerobic electrode chamber D ( Inert porous conductive material I is added in the top closed). The seeded activated sludge is injected into the aerobic electrode chamber through the top of the aerobic electrode chamber, so that the activated sludge is in full contact with the inert porous conductive material. The remaining activated sludge flows into the anoxic / anaerobic electrode chamber through the isolation tank C, and the activated sludge fully contacts with the inert porous conductive material. Afterwards, the...

Embodiment 3

[0056] to deal with NH 4 + -The sewage with N concentration of 1800mg / L is an embodiment, and the operation process of the process of the present invention is described:

[0057] (1) Sewage enters the grid and grit chamber to remove suspended large particles.

[0058] (2) The sewage that removes suspended large particles enters the aerobic electrode chamber. The dissolved oxygen content in the aerobic electrode chamber is greater than 1 mg / L, preferably 2 to 5 mg / L, and the present embodiment is controlled at 2 to 3 mg / L to monitor the DO (dissolved oxygen) of sewage in the aerobic electrode chamber. When DO is lower than 2 mg / L When L, increase the operating voltage of the aerobic electrode chamber to increase the rate of oxygen generation. The pH value is controlled at 6.0-9.0, preferably 6.5-8.5, and in this embodiment is controlled at 7.2-8.5. Monitor the pH value of the sewage in the aerobic electrode chamber. Due to the nitrification reaction of the electrolytic reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com