Tri-functionality urethane acrylate based on trimethylolethane/trimethylolpropane and preparation method and application of tri-functionality urethane acrylate

A technology of urethane acrylate and trimethylol ethane is applied in the field of materials, which can solve the problems of difficult control of the production process, many steps in the reaction process, gelation and the like, and achieves the effects of easy control, reduction of reaction steps and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

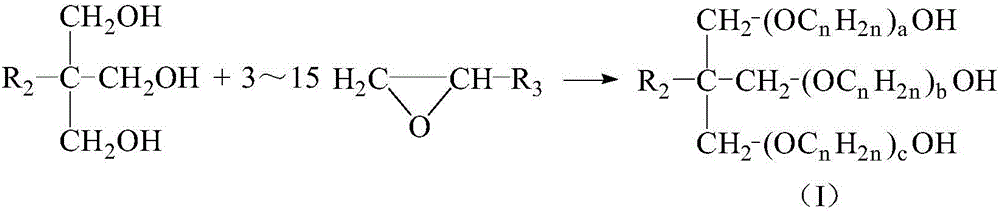

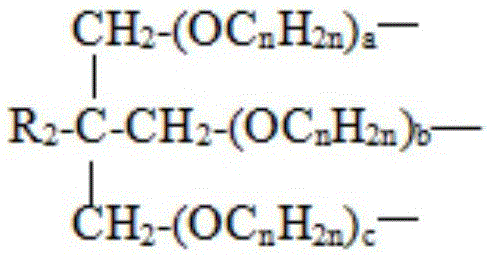

[0036] 1200 grams of trimethylolethane (CAS No. 77-85-0, molecular formula C) was dropped into a 6L autoclave 5 h 12 o 3 , molecular weight 120.147), 38 grams of sodium formate, warming up to 155 ° C, began to drop ethylene oxide (C 2 h 4 O, molecular weight 44) 2200 grams of reaction, temperature control 155 ° C ~ 165 ° C, pressure 0.2 ~ 0.6 MPa, dropwise for 3 ~ 4 hours, after the drop is completed, 155 ° C ~ 165 ° C for 2 ~ 3 hours, and then cooled to 80 ° C Below, the crude product is obtained in discharging; after adding 40 grams of activated clay to the crude product and stirring for 30 minutes, the clear and transparent trihydroxypolyether (C 15 h 32 o 8 , molecular weight 340) 3455.4 grams, structure as shown in formula (I), wherein: n=2, a+b+c=5.

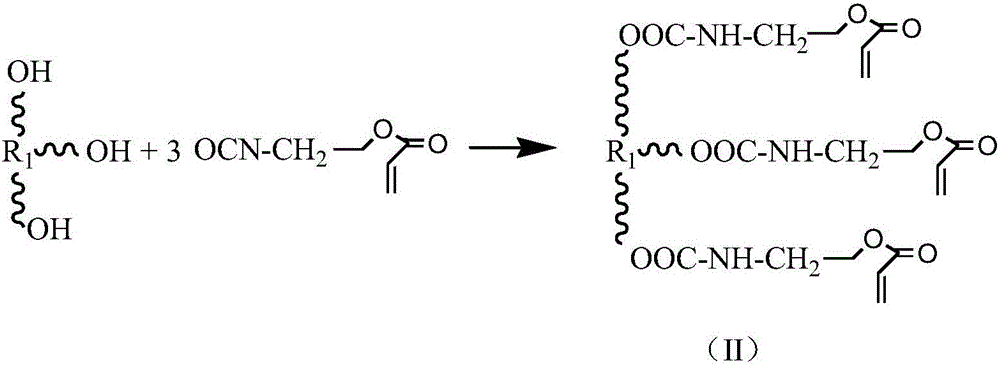

[0037] In the 1000mL four-necked flask, drop into the prepared trihydroxy polyether (C 15 h 32 o 8 , molecular weight 340) 170 grams, isocyanate ethyl acrylate 211.5 grams (1.5mol), catalyst dibutyltin dilaurate 0....

Embodiment 2

[0042] 1340 grams of trimethylolpropane (CAS No. 77-99-6, molecular formula C) was dropped into a 6L autoclave 6 h 14 o 3 , molecular weight 134.1736), 60 grams of potassium formate, warming up to 155 ° C, began to drop propylene oxide (C 3 h 6 O, molecular weight 58) 3480 grams of reaction, temperature control 155 ° C ~ 165 ° C, pressure 0.2-0.6 MPa, dropwise for 3 ~ 4 hours, after the drop is completed, 155 ° C ~ 165 ° C for 2 ~ 3 hours, and then cooled to 80 ° C Below, the crude product is obtained in discharging; after adding 60 grams of activated clay to the crude product and stirring for 30 minutes, the clear and transparent trihydroxypolyether (C 24 h 50 o 9 , molecular weight 482) 4722.4 grams, structure as shown in formula (I), wherein: n=3, a+b+c=6.

[0043] In the 1000mL four-necked flask, drop into the prepared trihydroxy polyether (C 24 h 50 o 9 , molecular weight 482) 241 grams, isocyanate ethyl acrylate 210 grams (1.488mol), catalyst dibutyltin dilaurat...

Embodiment 3

[0048] The preparation method of Example 1-2 provided in Chinese patent ZL201310146346.8 was used to prepare 3-functionality urethane acrylate, and as Comparative Example 1-2, examine Example 1-2 of the present invention and Comparative Example 1-2 to obtain The viscosity of 3-functionality urethane acrylates.

[0049] Test method: NDJ-1 rotary viscometer, No. 4 rotor, 60 rpm. Refer to "NDJ-1 Rotational Viscometer Instruction Manual" for specific operation steps.

[0050] Table 1 Viscosity of 3-functionality polyurethane acrylate

[0051]

Comparative example 1

Example 1

Comparative example 2

Example 2

viscosity

7200mPa.s@60℃

3600mPa.s@60℃

7700mPa.s@60℃

3900mPa.s@60℃

[0052] Compared with the product of Comparative Example 1, the viscosity of the product of Example 1 decreased by 3600mPa.s@60°C, and the rate of decrease was 50.00%.

[0053] Compared with the product of Comparative Example 2, the viscosity of the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com