Environment-friendly high-strength nail-free glue not containing organic tin and preparation method thereof

A nail-free glue and viscosity technology, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of limiting the practical application of nail-free glue, less than 2.0MPa, and poor initial adhesion, and achieve shortening Construction period, improved initial tack, good tear strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

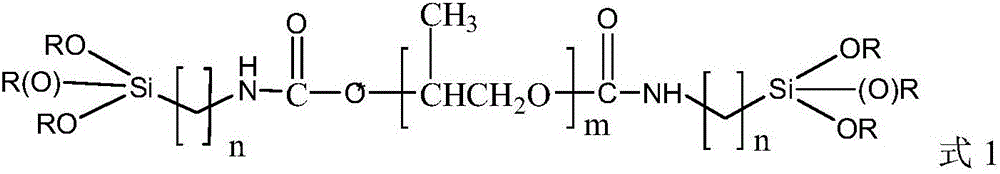

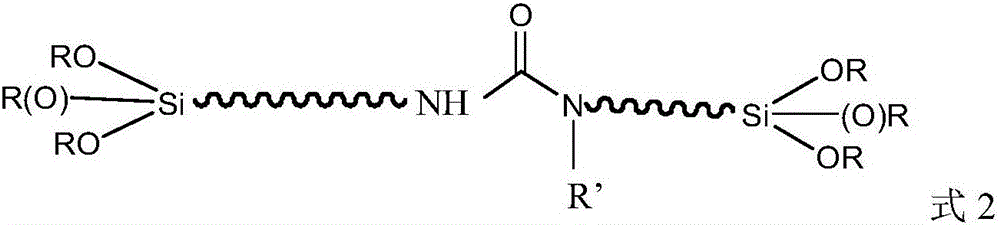

Method used

Image

Examples

Embodiment 1

[0065] Raw material composition and mass parts in the embodiment 1 of table 1

[0066]

[0067] The preparation method of nail-free glue is as follows:

[0068] S1. Add 15 parts of plasticizer and 38 parts of light calcium carbonate into the vacuum kettle, heat up to 110°C while stirring, decompress and vacuumize, heat and stir to dehydrate until the water content is less than 1000ppm;

[0069] S2. Stop the machine and cool down to 30°C, fill with nitrogen to release the vacuum to normal pressure, and then prepare the dehydrated glue;

[0070] S3. Open the kettle, add 20 parts of silane-terminated polymer and 20 parts of reinforcing resin to the dehydration mortar, close the kettle, decompress and vacuumize to remove the air and moisture in the kettle, stir at a medium speed for 10 minutes to mix the raw materials evenly;

[0071] S4. Shut down and open the kettle, add 4 parts of hydrophobic fumed silica, stir at high speed for 20 minutes to disperse evenly;

[0072] S5. ...

Embodiment 2

[0076] Raw material composition and mass parts in the embodiment 2 of table 2

[0077]

[0078]

[0079] The preparation method of the nail-free glue is as in Example 1.

Embodiment 3

[0081] Raw material composition and mass parts in the embodiment 3 of table 3

[0082]

[0083] The preparation method of the nail-free glue is as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com