Preparation technology of Zr-B-N nano-composite coating

A nano-composite coating and preparation process technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of short crack propagation path, reduced coating toughness, easy breakage, etc., and achieve a good combination Strength, improving coating toughness, good effect of impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

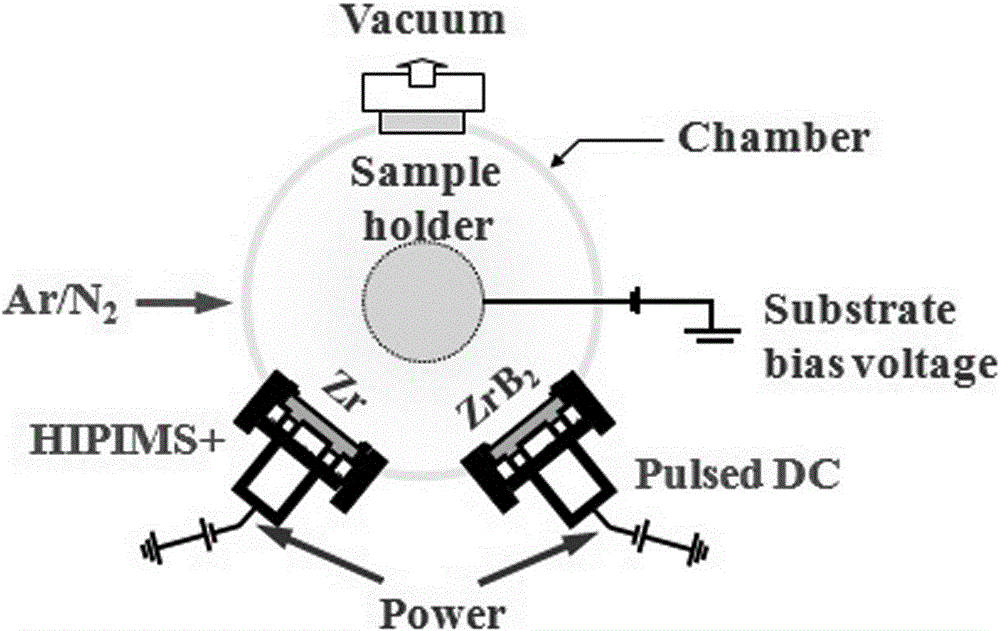

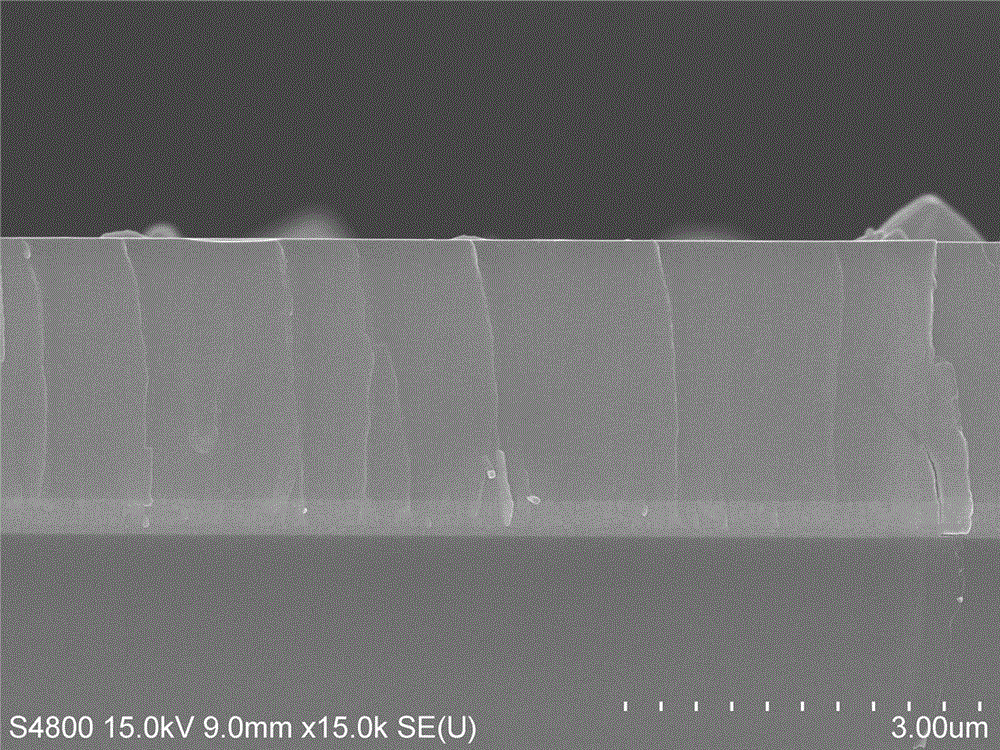

[0026] In this example, a Zr-B-N coating is deposited on a mirror-polished single-crystal Si wafer ((100) orientation), and the sample size is 40×30×0.7 mm. The substrate was ultrasonically cleaned in acetone and alcohol solutions for 20 minutes respectively, then dried with high-purity nitrogen, and then placed on the sample holder in the vacuum chamber facing the target. The coating process is carried out on a V-TECH AS610 high-power pulse and pulse DC composite magnetron sputtering coating machine, and the cathode target materials are metal Zr and compound ZrB respectively. 2 (purity is wt.99.9%), the working gas and reaction gas are respectively Ar and N 2 (both purity 99.999%), figure 1 The target layout diagram for high power pulsed and pulsed DC magnetron sputtering.

[0027] First, the background vacuum of the vacuum chamber is evacuated to 2.0×10 -3 Pa, and then argon gas was introduced into the vacuum chamber to perform glow discharge cleaning on the surface of t...

Embodiment 2

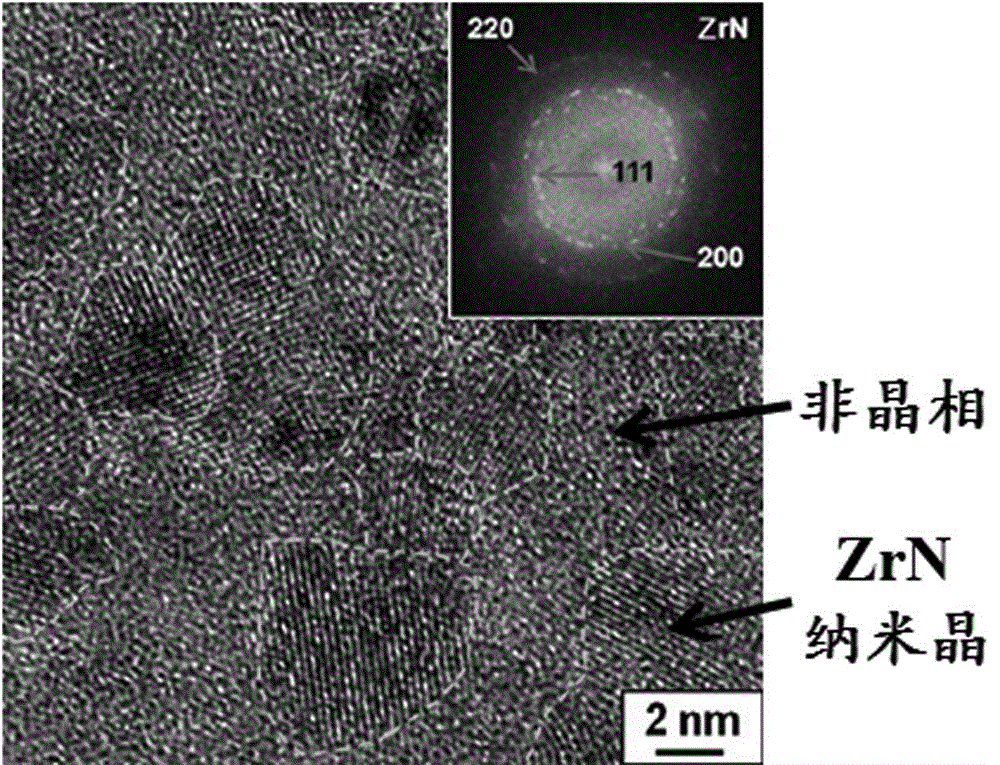

[0030] In this example, a Zr-B-N coating is deposited on a mirror-polished AISI 304 stainless steel substrate (Cr-18.5, Ni-9.4, Mn-0.8, Si-0.4, P-0.1, Fe balance, all by weight percentage) , the sample size is 30×25×1 mm. The substrate was first ground and polished by metallographic sandpaper, then ultrasonically cleaned with acetone and alcohol solutions respectively, dried and placed on the sample holder facing the target in the vacuum chamber. The deposition parameters are the same as in Example 1. Same as Example 1, there are ZrN phase and amorphous BN phase preferentially growing along the (001) crystal plane in the coating.

[0031] Using nano-indentation technology, the hardness of Zr-B-N coating deposited on the stainless steel substrate was tested by continuous stiffness method. The measurement results were in the range of 45.4-50.2 GPa, and the average value of ten measurements was 48.2 GPa. The coating has a high hardness. The bonding strength between the coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com