Pipeline system capable of resisting leakage, heat and corrosion and construction method of pipeline system

A technology for composite pipes and pipe joints, which is applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of low anti-corrosion performance of welding parts, leakage of pipe joints, and decline in pipe strength, so as to prevent the formation of mineral scale and gas Good tightness and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

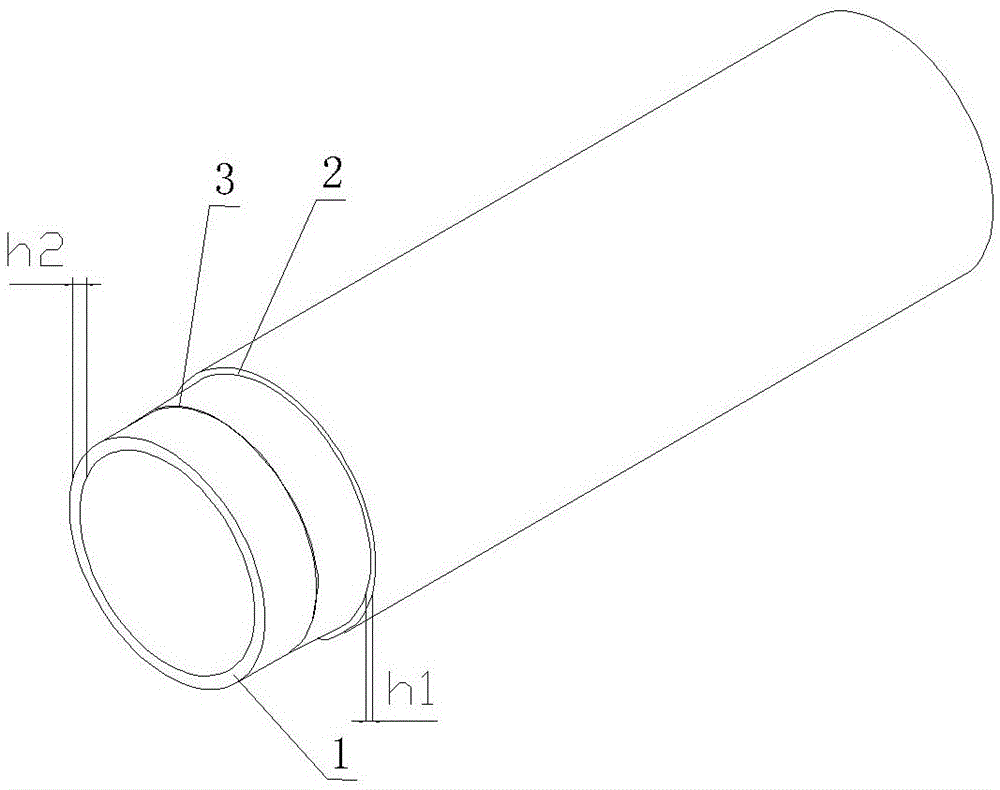

[0036] A composite pipe made of thin-walled stainless steel and reinforced PE plastic, the structure includes a stainless steel outer layer 2, a PE plastic inner layer 1 and an adhesive layer 3 in the middle, wherein:

[0037] A. The stainless steel tube is made of a plate with a thickness of h1=0.2mm, which is formed by laser synchronous roll welding;

[0038] B. Reinforced PE is made of high-density polyethylene pipe treated with cobalt 60 irradiation, the irradiation intensity is not less than 120KGy, and the wall thickness h2=2mm;

[0039] C. The inner diameter of the composite pipe is 22mm.

[0040] The material used for the adhesive layer 3 is steel-plastic composite resin glue.

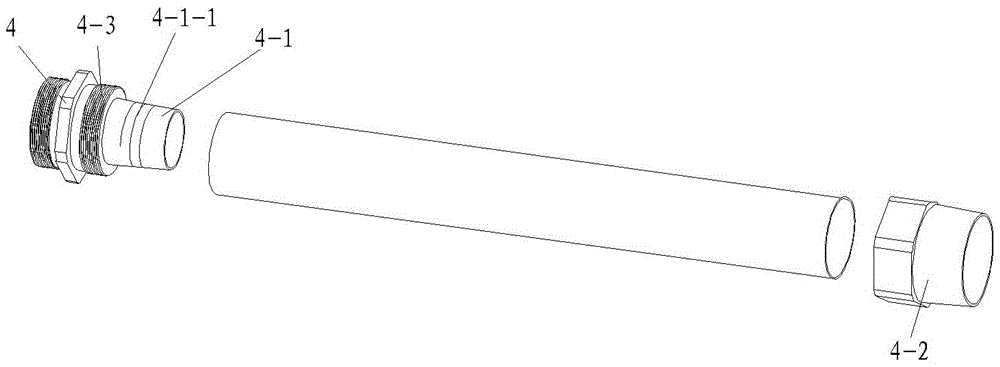

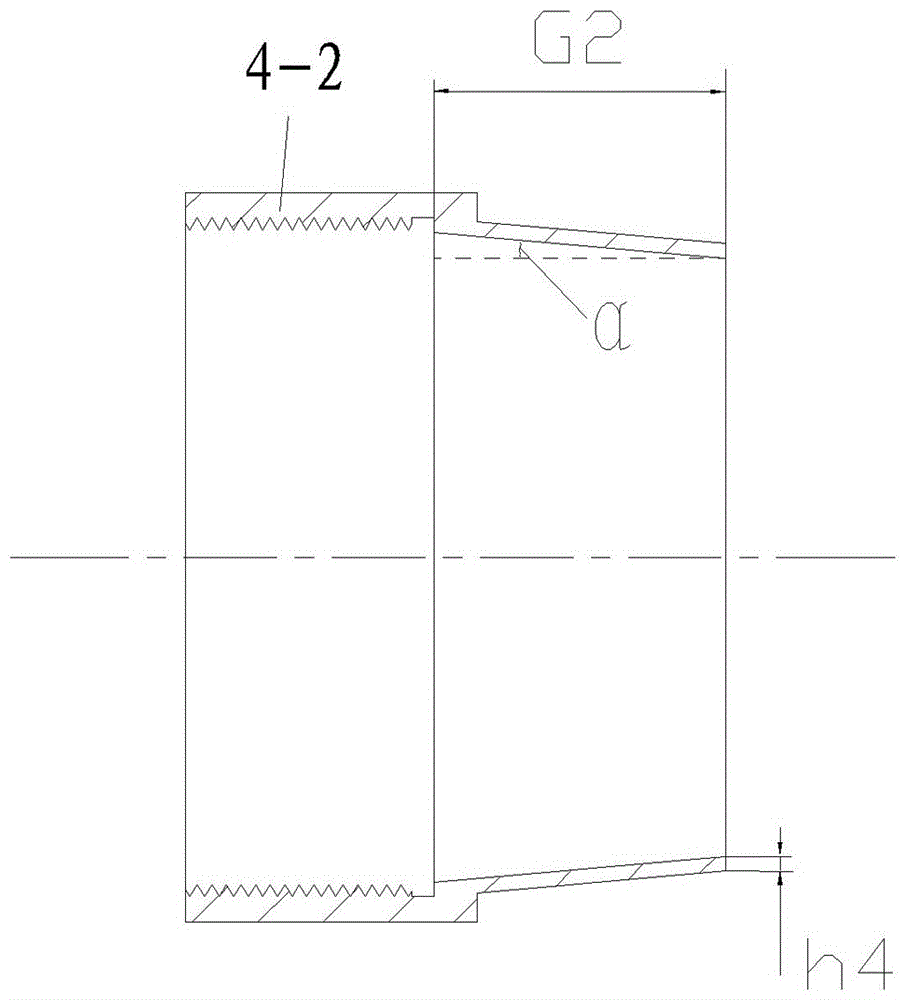

[0041] The connecting device of the composite pipe is provided with at least one pipe joint that is docked with the composite pipe, and the structure of the pipe joint includes an inner cylindrical outer circular frustum-shaped sleeve pipe head 4-1 positioned on the main body 4 of the pipe joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com