Homogeneous-phase anion-exchange membrane and preparation method thereof

An anion-exchange membrane and membrane liquid technology, applied in the field of homogeneous anion-exchange membrane and its preparation, can solve problems such as complex steps, environmental pollution, ion exchange capacity loss, etc., and achieve improved comprehensive performance, high mechanical strength, and enhanced dimensional stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

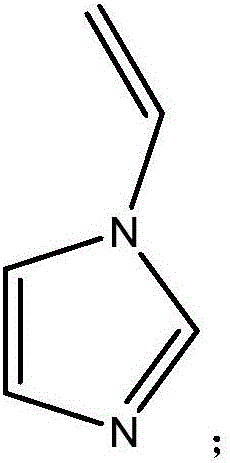

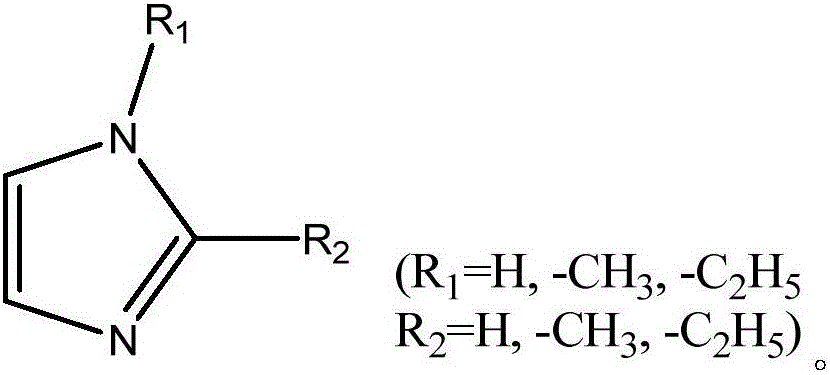

[0025] Dissolve 1 g of bromomethylated poly(1,4-dimethyl 2,6-phenylene oxide) (BPPO) in a mixed solution consisting of 0.25 mL of p-chloromethyl styrene and 1.8 mL of styrene at room temperature. Stir to obtain a uniform solution; add 0.35mL vinylimidazole dropwise to the uniform solution, stir until the solution is uniform, then add 0.075mL methimidazole dropwise, after stirring evenly, apply the film solution evenly on the coating plate, at 100 After drying at ℃ for 12 hours, a film was formed to obtain a homogeneous anion exchange membrane.

[0026] The homogeneous anion exchange membrane that present embodiment obtains is carried out infrared test, and the result is: 1653cm -1 and 1604cm -1 The characteristic peak corresponding to the double bond in the structure, 2923cm -1 and 2960cm -1 Respectively correspond to -CH 2 -and-CH 3 The vibration peak of , 3060cm -1 It is the characteristic peak of -N=C-H on the imidazole group, which proves the occurrence of quaterniza...

Embodiment 2

[0029] This example adopts the same operation process as Example 1, the only difference is that the amount of p-chloromethylstyrene is increased to 0.5mL, and then the amount of vinylimidazole and methylimidazole is adjusted to 0.45mL and 0.15mL respectively, to obtain Structurally similar homogeneous anion exchange membranes.

[0030] After testing, the water content and ion exchange capacity of the anion exchange membrane prepared in this example are 64.1% and 2.14mmol / g-dry film respectively, the ion transfer number is 0.93, and the membrane resistance is 1.12Ω·cm 2 . Experimental data show that the membrane has good conductivity and high anion selectivity, and can be used in the field of electrodialysis.

Embodiment 3

[0032] This example adopts the same operation process as Example 1, the only difference is that the dosage of p-chloromethylstyrene is increased to 0.75mL, and then the dosage of vinylimidazole and methylimidazole is adjusted to 0.53mL and 0.23mL respectively, to obtain Structurally similar homogeneous anion exchange membranes.

[0033] After testing, the water content and ion exchange capacity of the anion exchange membrane prepared in this example are 77.5% and 2.3mmol / g-dry film respectively, the ion migration number is 0.95, and the membrane resistance is 1.12Ω·cm 2 . Experimental data show that the membrane has good conductivity and high anion selectivity, and can be used in the field of electrodialysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transference number | aaaaa | aaaaa |

| transference number | aaaaa | aaaaa |

| transference number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com