Preparation method of double-interface catalyst for one-process hydrogen production-hydrogenation coupling reaction and application of catalyst

A coupling reaction and catalyst technology, which is applied in the preparation method of double-interface catalysts and the application field of catalysts, can solve the problems such as the method and method of hydrogen production-hydrogenation series catalysts that have not been publicly reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

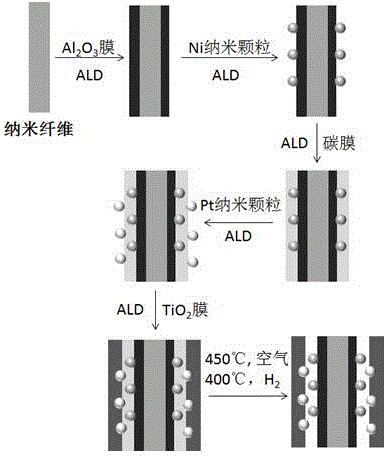

[0044] 1) Mix and disperse self-made carbon nanocoils (CNCs) with ethanol to form a uniform suspension, the concentration of the sample is 0.01g / ml, coat the surface of the glass sheet, evaporate to dryness and place it in the atomic layer deposition chamber, the chamber The pressure is 70Pa, and the flow rate of the carrier gas is fixed during the deposition process.

[0045] 2) Aluminum oxide film is deposited on the surface of carbon helix by atomic layer deposition technology. The deposition parameters are set as follows: the reaction temperature is 150° C., the temperature of the reaction source trimethylaluminum and water is 25° C., and the flow rate of nitrogen gas is 50 sccm. First pulse trimethylaluminum vapor into the deposition chamber with a pulse time of 0.02 s, a hold time of 5 s, and a purge time of 15 s; then pulse water vapor into the deposition chamber with a pulse time of 0.1 s and a hold time of 15 s. The sweeping time is 20s, and a deposition cycle is com...

Embodiment 2

[0053] The test was carried out with the same method as in Example 1, and the difference from Example 1 was that the number of cycles of the polyimide organic thin film of the sacrificial layer was 80 cycles. At this time Al 2 o 3 / Ni-Pt / TiO 2 The yield of aniline on the catalyst reaches 50% within 0.5 hours, and reaches more than 98% within 3 hours. This indicates that the intrinsic activity of the catalyst can be changed by changing the thickness of the sacrificial layer.

Embodiment 3

[0055] 1) TiO 2 The nanowires are mixed with ethanol to form a uniform suspension, the concentration of the sample is 0.05g / ml, coated on the surface of the glass sheet, evaporated to dryness and placed in the atomic layer deposition chamber, the chamber pressure is 50Pa, the carrier gas during the deposition process The traffic is fixed.

[0056] 2) on TiO 2 Platinum nanoparticles are deposited on the surface of the nanowires. The set deposition parameters are: The set deposition parameters are: the reaction temperature is 220°C, the temperature of the reaction source trimethylcyclopentadiene platinum is 60°C, the ozone or oxygen temperature is 2°C, and the nitrogen flow rate is 50sccm . First pulse trimethylmethylcyclopentadiene platinum vapor into the deposition chamber, the pulse time is 1s, the hold time is 10s, and the purge time is 25s; then pulse oxygen into the deposition chamber, the pulse time is 0.1s, the hold time is 25s. is 12s, and the purging time is 30s, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com