Synthetic method of chitosan biomass-derived high-yield nitrogen-doped fluorescent carbon nanodots

A technology of carbon nano-dots and synthesis methods, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of low synthesis yield, achieve high synthesis yield, reduce production cost, Effect without post-passivation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A kind of synthetic method of the high-yield nitrogen-doped fluorescent carbon nano-dot originating from chitosan biomass in the present embodiment is completed by following steps:

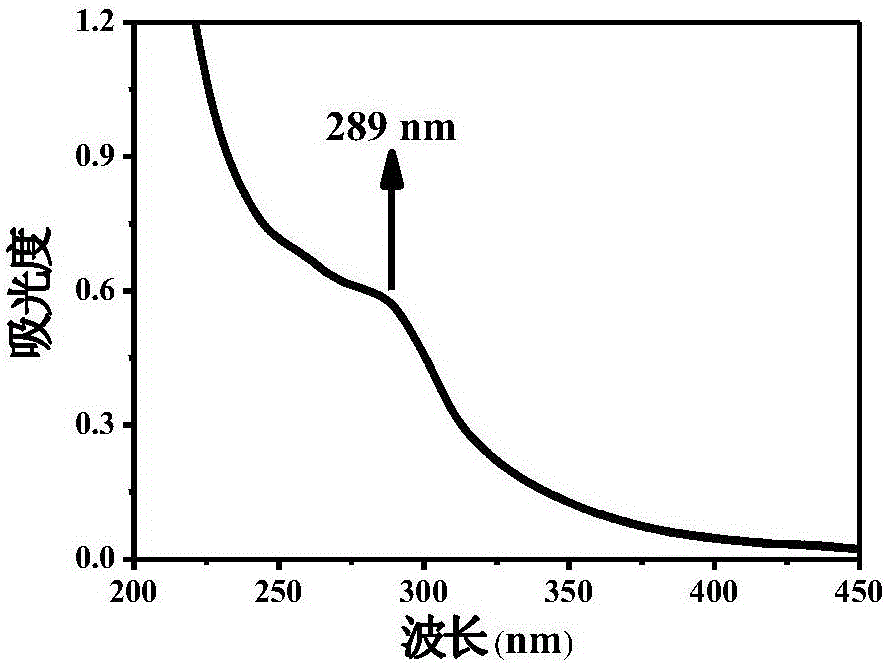

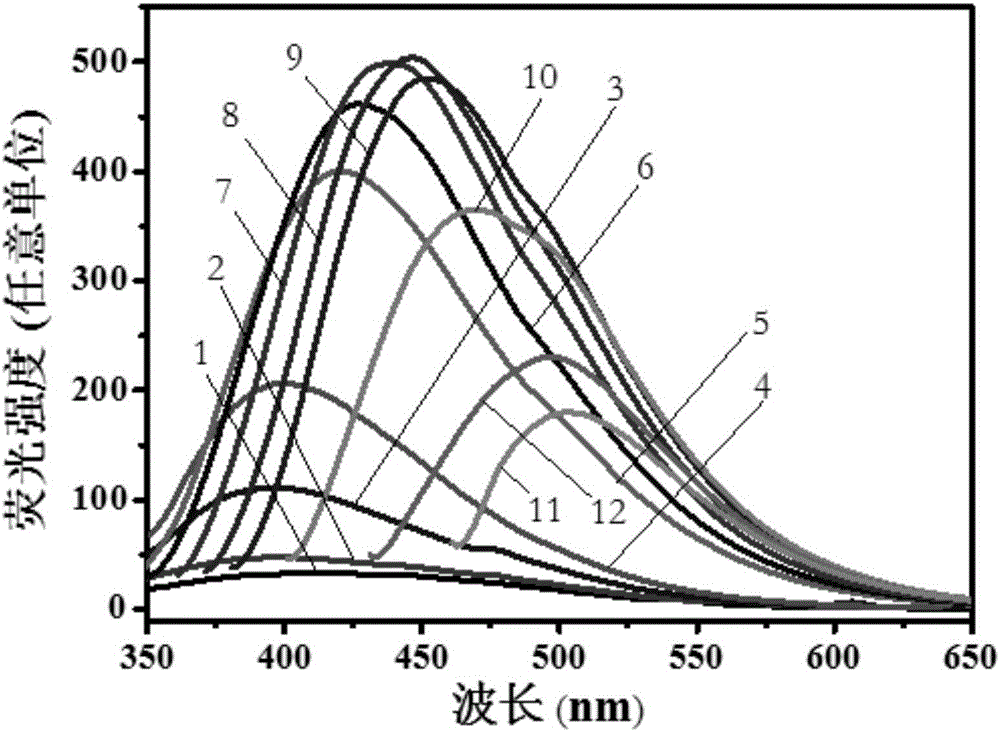

[0022] Dissolve 0.1g chitosan derivatives containing unsaturated double bonds in 20mL of ultrapure water, configure an aqueous solution with a concentration of 1mg / mL, place it in a reaction kettle, and then heat it at 180°C The carbonization reaction was taken out after 12 hours. Centrifuge the reaction solution at a speed of 15000r / min for 10min to remove the black precipitate particles in the reaction solution, and finally use a dialysis membrane with a molecular weight cut-off of 1kD to dialyze in deionized water for 48h to obtain a nitrogen-doped fluorescent carbon nanodot solution. Freeze-dry to obtain a nitrogen-doped fluorescent carbon nano-dot solid sample with a yield of 46%. The structure of the described unsaturated double-bond chitosan derivative is as follows: ...

Embodiment 2

[0026] Embodiment 2: A kind of synthetic method of the high-yield nitrogen-doped fluorescent carbon nano-dot originating from chitosan biomass in the present embodiment is completed by the following steps:

[0027] Dissolve 0.5g chitosan derivatives containing unsaturated double bonds in 20mL of ultrapure water to form an aqueous solution with a concentration of 5mg / mL. The carbonization reaction was taken out after 12 hours. Centrifuge the reaction solution at a speed of 15000r / min for 10min to remove the black precipitate particles in the reaction solution, and finally use a dialysis membrane with a molecular weight cut-off of 1kD to dialyze in deionized water for 48h to obtain a nitrogen-doped fluorescent carbon nanodot solution. Freeze-dry to obtain a nitrogen-doped fluorescent carbon nano-dot solid sample with a yield of 42%. The structure of the chitosan derivative containing unsaturated double bonds in this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0028] Embodiment 3: A kind of synthetic method of the high-yield nitrogen-doped fluorescent carbon nano-dot originating from chitosan biomass in the present embodiment is completed by the following steps:

[0029] Dissolve 1g of chitosan derivatives containing unsaturated double bonds in 20mL of ultrapure water to form an aqueous solution with a concentration of 10mg / mL, place it in a reaction kettle, and then conduct hydrothermal carbonization at a temperature of 220°C Take it out after 24 hours of reaction. Centrifuge the reaction solution at a speed of 15000r / min for 10min to remove the black precipitate particles in the reaction solution, and finally use a dialysis membrane with a molecular weight cut-off of 1kD to dialyze in deionized water for 48h to obtain a nitrogen-doped fluorescent carbon nanodot solution. Freeze-dry to obtain a nitrogen-doped fluorescent carbon nano-dot solid sample with a yield of 40%. The structure of the chitosan derivative containing unsaturat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com