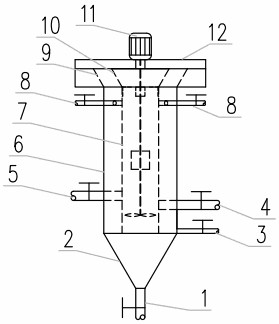

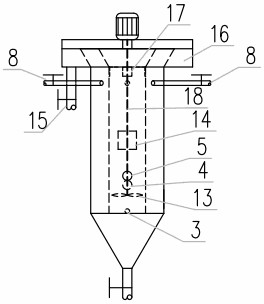

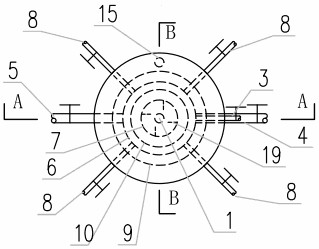

A phosphorus recovery reactor

A reactor and phosphorus recovery technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as increased operating costs, increased operating costs, and blockages. Achieve the effects of reducing the probability of crystal loss, ensuring no loss, and high phosphorus recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1 The recovery of phosphorus in phosphorus-containing wastewater

[0081] 10L of phosphorus-containing wastewater was collected; the phosphorus-containing wastewater came from untreated aquaculture wastewater from a farm in Chongqing, and the phosphorus content in the wastewater was measured to be 40mg / L.

[0082] Take phosphorus-containing wastewater (calculated by the mass of phosphorus) and the excess interplanar spacing is 1.3nm, which has peaks at 0.304nm and 0.280nm, and the infrared characteristic peak is: δ(Si-O-Si) 455cm -1 , V δ (Si-O-Si) 652 cm -1 , V(Si-O)Q 1 816cm -1 , V(Si-O)Q 2 970cm -1 After mixing 10g of calcium silicate hydrate crystals with a calcium-silicon molar ratio of 1:1~1.5:1, it is mixed with excess carbonate (carbonate includes sodium carbonate, sodium bicarbonate or calcium bicarbonate. As long as it can Provide CO 3 2- , all phosphates known to those skilled in the art are within the protection scope of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com