Silicon dioxide-based anti-adhesion agent used for polyolefin thin film and preparation method thereof

A technology of silica and anti-blocking agent, which is applied in the field of silica-based anti-blocking agent for polyolefin film and its preparation, can solve the problem of affecting the printability, heat-sealability and color of plastic film, and affecting the safety of plastic film food packaging materials. It can improve the anti-blocking effect, enhance the anti-blocking effect and improve the compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of silicon dioxide-based anti-blocking agent for polyolefin film, wherein, comprises the following steps:

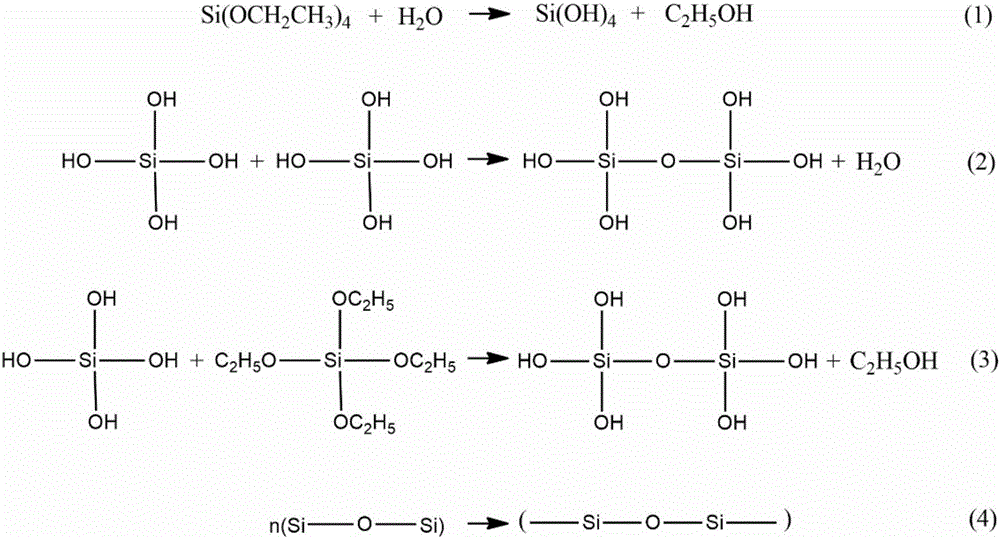

[0025] Step 1: Mix 18g (18wt%) distilled water and 28g (28wt%) absolute ethanol evenly, add 16g (16wt%) ammonia water therein, and stir at 25°C for 20min. A mixed solution of 10 g (10 wt %) of ethyl tetrasilicate and 28 g (28 wt %) of absolute ethanol was slowly added dropwise to the system under stirring. After the dropwise addition, react at 25°C for 4h. The obtained solution is separated by a centrifuge, and the milky white solution in the upper layer obtained is SiO 2 Sol. The upper layer solution was separated and dried to obtain SiO 2 particles. In this step, tetraethyl orthosilicate undergoes hydrolysis reaction, and the reaction process is as follows: figure 1 shown.

[0026] Step 2, the SiO obtained above with 10g 2 The solid particles were added to a mixture of 0.5g CTAB, 20g n-octanol and 70g water, and stirred by a s...

Embodiment 2

[0029] A kind of preparation method of silicon dioxide-based anti-blocking agent for polyolefin film, wherein, comprises the following steps:

[0030]Step 1: Mix 22g (22wt%) distilled water and 22.5g (22.5wt%) absolute ethanol evenly, add 20g (20wt%) ammonia water to it, and stir at 25°C for 20min. A mixed solution of 13 g (13 wt %) of tetraethyl orthosilicate and 22.5 g (22.5 wt %) of absolute ethanol was slowly added dropwise to the system under stirring. After the dropwise addition, react at 25°C for 6h. The obtained solution is separated by a centrifuge, and the milky white solution in the upper layer obtained is SiO 2 Sol. The upper layer solution was separated and dried to obtain SiO 2 particles. In this step, tetraethyl orthosilicate undergoes hydrolysis reaction, and the reaction process is as follows: figure 1 shown.

[0031] Step 2, the SiO obtained above with 10g 2 The solid particles were added to a mixture of 0.6 g of SDS, 35 g of dodecane and 55 g of water...

Embodiment 3

[0034] A kind of preparation method of silicon dioxide-based anti-blocking agent for polyolefin film, wherein, comprises the following steps:

[0035] Step 1: Mix 25g (25wt%) distilled water and 25g (25wt%) absolute ethanol evenly, add 10g (10wt%) ammonia water therein, and stir at 25°C for 20min. A mixed solution of 15 g (15 wt %) of ethyl tetrasilicate and 25 g (25 wt %) of absolute ethanol was slowly added dropwise to the system under stirring. After the dropwise addition, react at 25°C for 8h. The obtained solution is separated by a centrifuge, and the milky white solution in the upper layer obtained is SiO 2 Sol. The upper layer solution was separated and dried to obtain SiO 2 particles. In this step, tetraethyl orthosilicate undergoes hydrolysis reaction, and the reaction process is as follows: figure 1 shown.

[0036] Step 2, the SiO obtained above with 10g 2 The solid particles were added to a mixture of 0.8g SDBS, 50g hexadecane and 40g water, and stirred by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com