Argentum (Ag)/cobaltous sulfide (CoS) supercapacitor electrode material and preparation method thereof

A technology for supercapacitors, electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

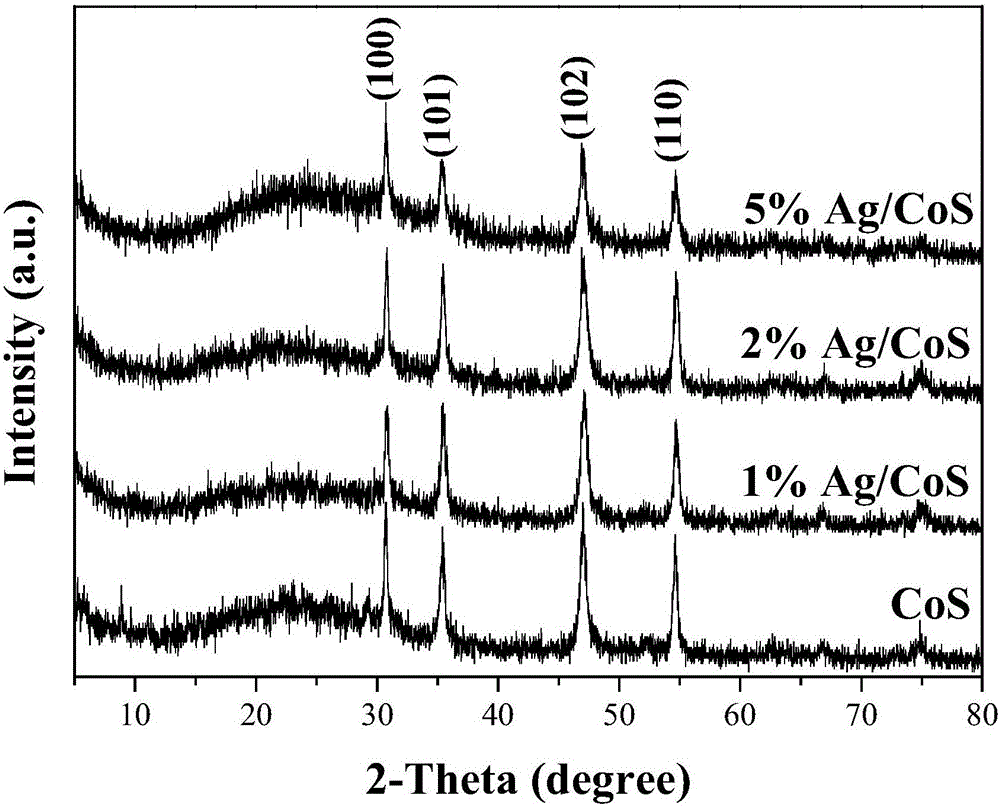

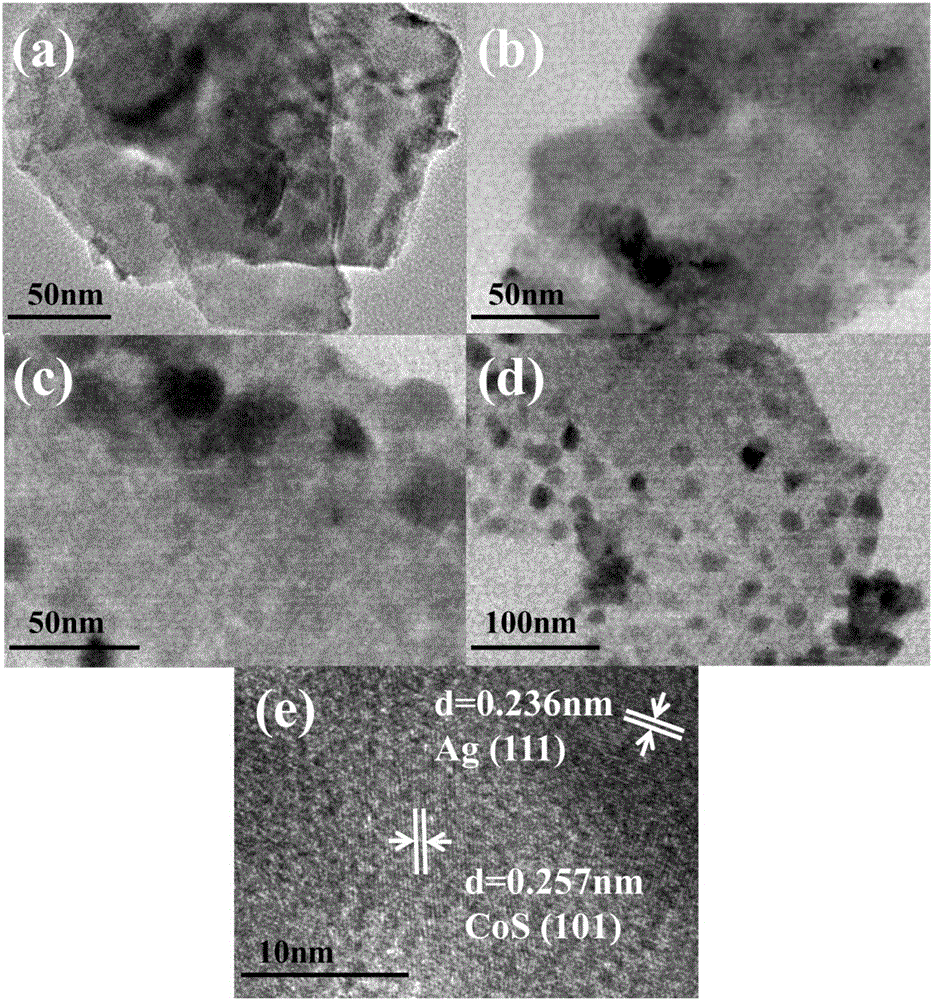

[0025] Embodiment 1: Preparation of CoS nanosheets:

[0026] The synthesis of CoS nanosheets adopts the method of solvothermal reaction: weigh 0.8mmol of CoCl 2 ·H 2 0 and 1.6mmol of thiourea in a 100mL beaker, add 37mL of absolute ethanol, and magnetically stir for 30min to completely dissolve it, then add 3.75mL of ethylenediamine, stir for another 10min, then add the resulting solution to a 50mL liner for poly Put it into a reaction kettle of tetrafluoroethylene, put it into an oven, and conduct a solvothermal reaction at 180°C for 12 hours. After the reaction is completed and cool to room temperature, centrifuge out the precipitate and wash it with water and alcohol three times, put it in an oven, dry it, and grind it to obtain CoS nanosheets .

Embodiment 2

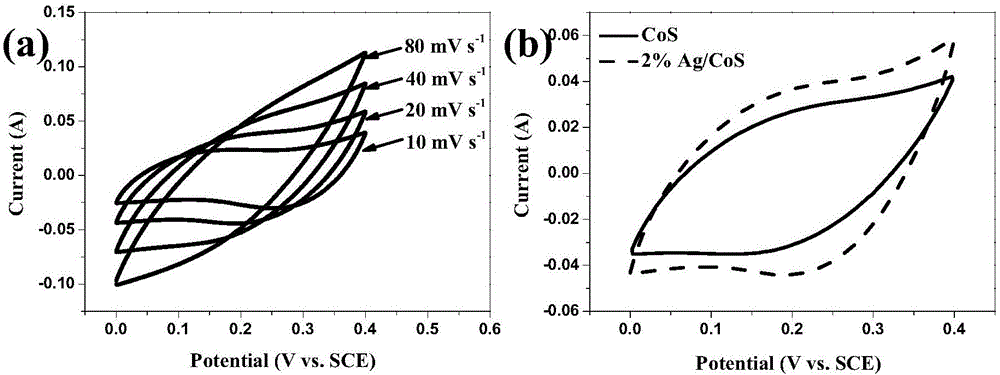

[0027] Embodiment 2: Preparation of 2%Ag / CoS composite nanomaterial:

[0028] The synthesis of 2% Ag / CoS composite nanomaterials adopts the photoreduction method: Weigh 0.1g of CoS powder into a 250mL beaker, add 100mL of distilled water, place it in an ultrasonic machine with a power of 100W for 30min, and then add 0.0032g of AgNO 3 And stir for 30min, wait for AgNO 3 After completely dissolving, place the beaker next to the 500W tungsten lamp light source, continuously stir and turn on the tungsten lamp light source, centrifuge the precipitate after 4 hours of light, wash with water and alcohol for 3 times each, put it in an oven, dry it, and grind it to get 2 %Ag / CoS composite.

Embodiment 3

[0029] Embodiment 3: Preparation of 1%Ag / CoS composite nanomaterial:

[0030] The synthesis of 1% Ag / CoS composite nanomaterials adopts the light reduction method: weigh 0.1g CoS powder in a 250mL beaker, add 100mL of distilled water, place it in an ultrasonic machine with a power of 100W for 30min, and then add 0.0016g AgNO 3 And stir for 30min, wait for AgNO 3 After completely dissolving, place the beaker next to the 500W tungsten lamp light source, continuously stir and turn on the tungsten lamp light source, centrifuge out the precipitate after 4 hours of light, wash with water and alcohol for 3 times, put it in an oven, dry it, and grind it to get 1 %Ag / CoS composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com