Production technology of pentaerythrityl tetrastearate

A technology for pentaerythritol and production technology, applied in the production technology field of pentaerythritol tetra-stearate, can solve problems such as high reaction temperature, difficult layered operation, polluted environment, etc., achieves lower reaction temperature, stable and reliable process, and lower production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

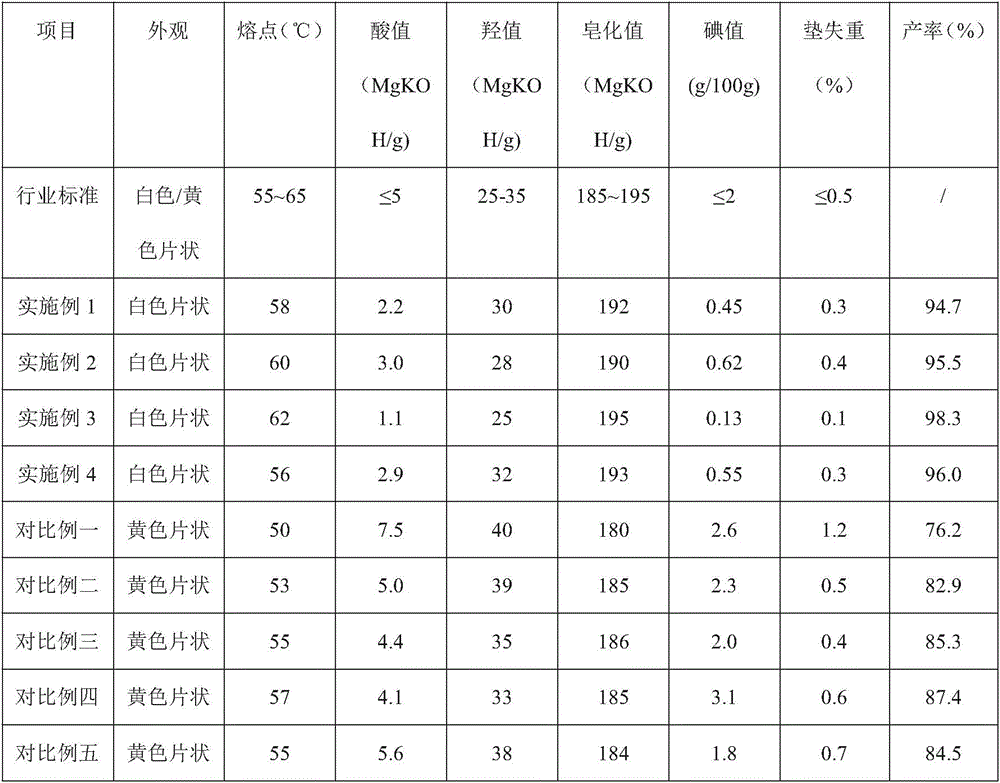

Examples

Embodiment 1

[0019] Embodiment 1, the production technique of pentaerythritol stearate tetraester of the present invention

[0020] S1, put in 1945.8kg of stearic acid, heat while stirring, until the stearic acid is completely melted and becomes a transparent liquid, continue to slowly put in 245.1kg of pentaerythritol and a catalyst with 0.2% weight of stearic acid, and then seal the feeding manhole well, and the reaction kettle Control to normal pressure, then slightly open N 2 , until there is a small amount of N at the exhaust port 2 foam overflow;

[0021] S2. Raise the temperature of the material to 115°C, keep it warm for 30 minutes, turn off N2, turn on the water ring vacuum pump, control the negative pressure at 0.03mpa, then raise the temperature of the material to 137°C, then increase the negative pressure to 0.06mpa, and react for 100 minutes;

[0022] S3. After the foam of the reactant completely disappears, increase the vacuum degree to 0.09mpa, and raise the temperature of...

Embodiment 2

[0025] Embodiment 2, the production technology of pentaerythritol stearate tetraester of the present invention

[0026] S1, put in 2048.3kg of stearic acid, heat while stirring, until the stearic acid is completely melted and becomes a transparent liquid, continue to slowly add 245.1kg of pentaerythritol and a catalyst of 1% by weight of stearic acid, and then seal the feeding manhole well, and the reaction kettle Control to normal pressure, then slightly open N 2 , until there is a small amount of N at the exhaust port 2 foam overflow;

[0027] S2. Raise the temperature of the material to 125°C, keep it warm for 30 minutes, turn off N2, turn on the water ring vacuum pump, control the negative pressure at 0.01mpa, then raise the temperature of the material to 143°C, then increase the negative pressure to 0.05mpa, and react for 80 minutes;

[0028] S3. After the foam of the reactant completely disappears, increase the vacuum degree to 0.07mpa, and raise the temperature of the...

Embodiment 3

[0031] Embodiment 3, the production technology of pentaerythritol stearate tetraester of the present invention

[0032] S1, put in 1997.0kg of stearic acid, heat while stirring, until the stearic acid is completely melted and becomes a transparent liquid, continue to slowly put in 245.1kg of pentaerythritol and a catalyst with 0.5% weight of stearic acid, and then seal the feeding manhole well, and the reaction kettle Control to normal pressure, then slightly open N 2 , until there is a small amount of N at the exhaust port2 foam overflow;

[0033] S2. Raise the temperature of the material to 120°C, keep it warm for 30 minutes, and turn off the N 2 , turn on the water ring vacuum pump, control the negative pressure at 0.02mpa, then raise the temperature of the material to 140°C, then increase the negative pressure to 0.05mpa, and react for 90 minutes;

[0034] S3. After the foam of the reactant completely disappears, increase the vacuum degree to 0.08mpa, and raise the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com