A cementing working fluid system prepared from waste drilling fluid and drill cuttings

A technology for discarding drilling fluids and working fluids, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem that the re-injection fluid has limited functions to improve the pressure bearing capacity of the formation, has no curable properties, and cannot be cemented. Working fluid and other problems, to achieve the effect of good recycling value, convenient on-site application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

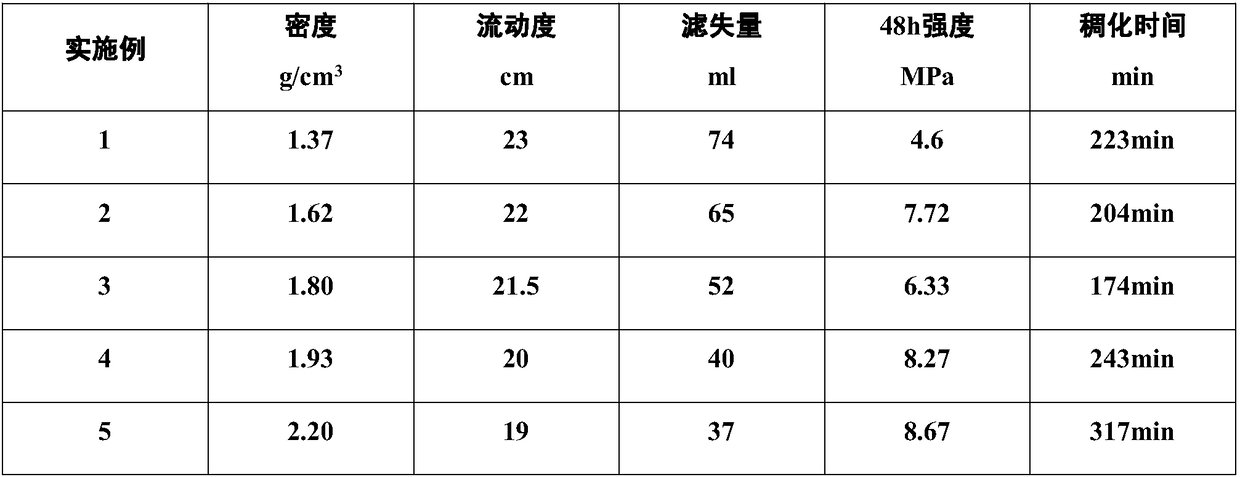

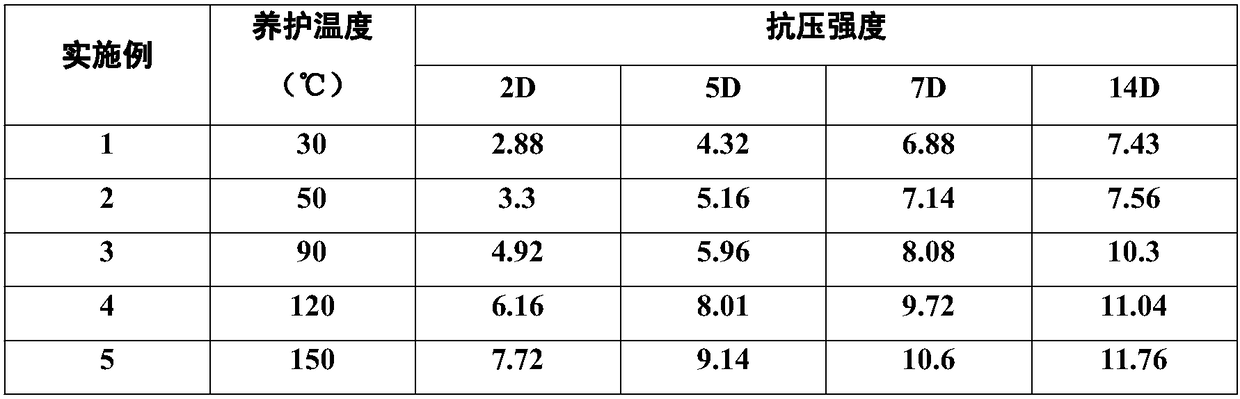

Embodiment 1

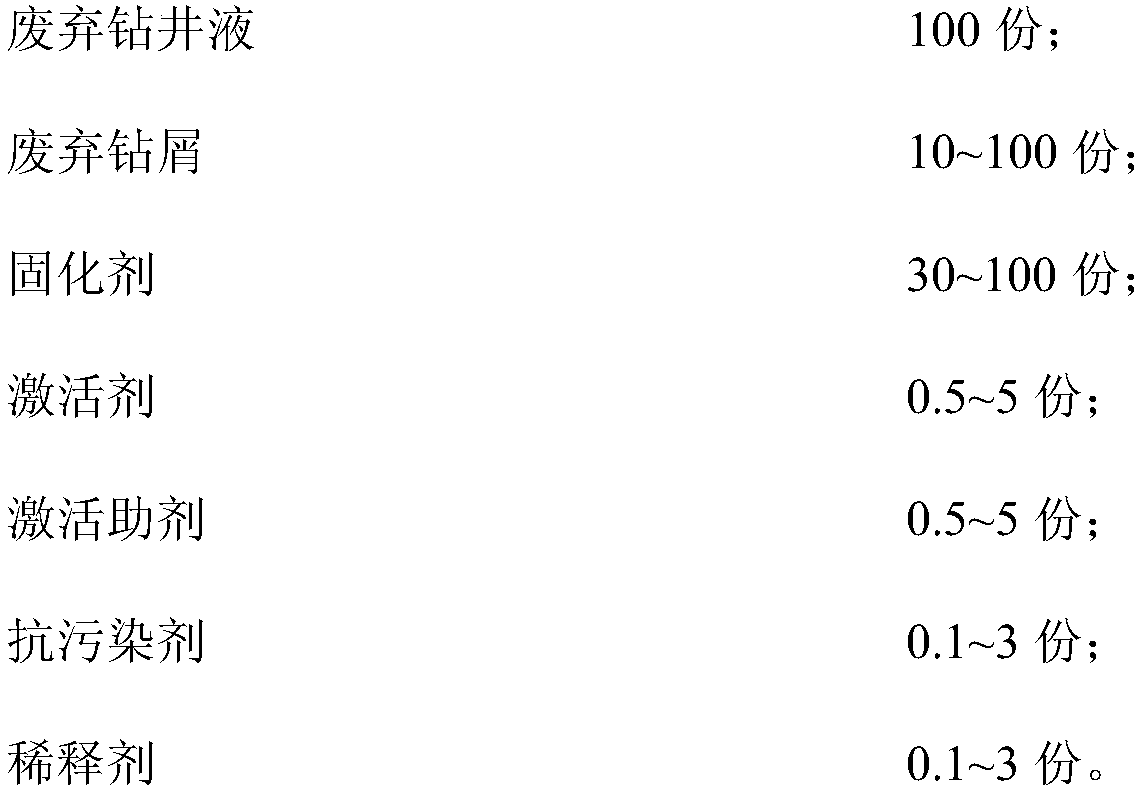

[0027] Recipe: waste drilling fluid (1.10g / cm 3 ) 100 parts, finely ground waste drill cuttings 10 parts, curing agent 30 parts, sodium hydroxide 0.5 part, sodium silicate nonahydrate 0.5 part, sodium pentaborate 0.1 part, hydroxyethyl cellulose 0.1 part.

Embodiment 2

[0029] Recipe: waste drilling fluid (1.20g / cm 3 ) 100 parts, finely ground waste drill cuttings 20 parts, curing agent 40 parts, potassium hydroxide 0.5 part, calcium carbonate 1 part, sodium salicylate 0.3 part, calcium lignosulfonate 0.5 part.

Embodiment 3

[0031] Recipe: waste drilling fluid (1.55g / cm 3 ) 100 parts, 40 parts of finely ground waste drill cuttings, 60 parts of curing agent, 2 parts of sodium hydroxide, 2 parts of sodium carbonate, 0.7 parts of potassium citrate, and 1 part of sodium lignosulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com