Method for efficiently producing cellulose based on preparation of mixture through glucose glucoside conversion reaction

A technology of cellulase and glucose, which is applied in the field of high-efficiency production of cellulase based on the preparation of mixtures based on glucose transglycoside reaction, can solve the problems of low enzyme activity, high cost, and low production intensity of cellulase, so as to reduce production costs and save The effect of process energy consumption and shortening fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1, β-glucosidase catalyzed glucose transglycoside reaction to prepare MGD

[0031] Prepare 600g / L glucose solution, add 20IU β-glucosidase produced by Xiasheng Industrial Group Co., Ltd. per gram of glucose, incubate at pH 4.8 and 65°C for 72 hours, then boil the glucose solution for 5 minutes to inactivate β-glucosidase Then the soluble inducer MGD can be prepared. It has been determined that MGD contains 410.3g / L of glucose and 13.7g / L of sophorose.

Embodiment 2

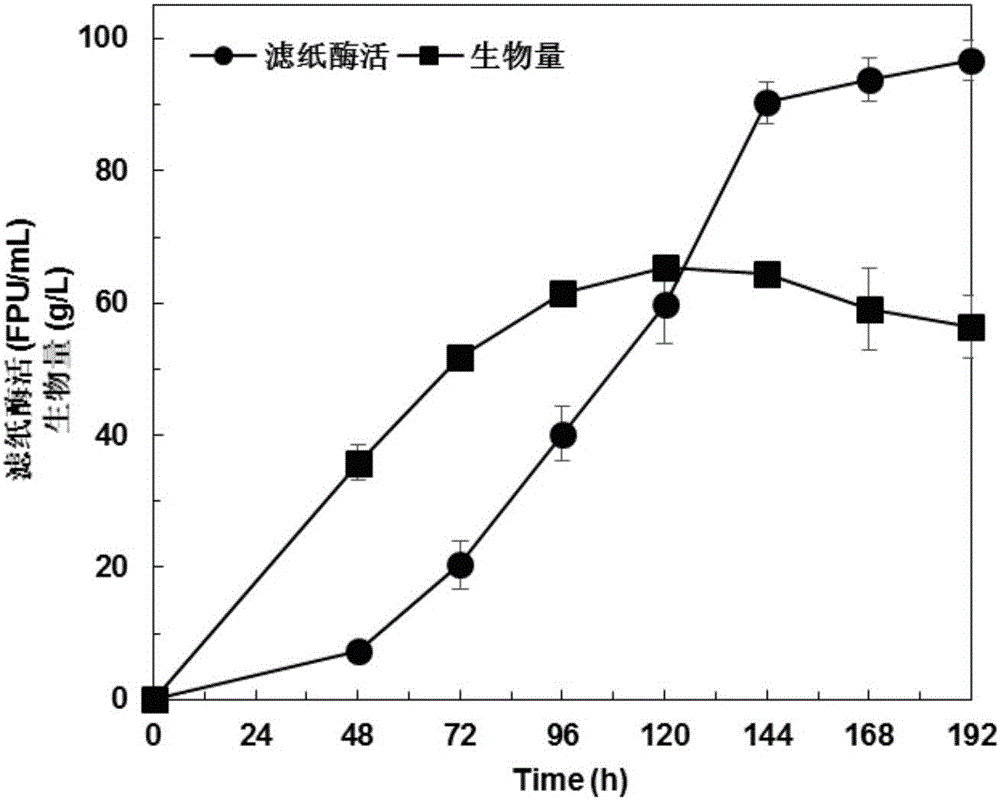

[0032] Example 2, batch feeding MGD culture T.reesei RUT C30 to efficiently produce cellulase

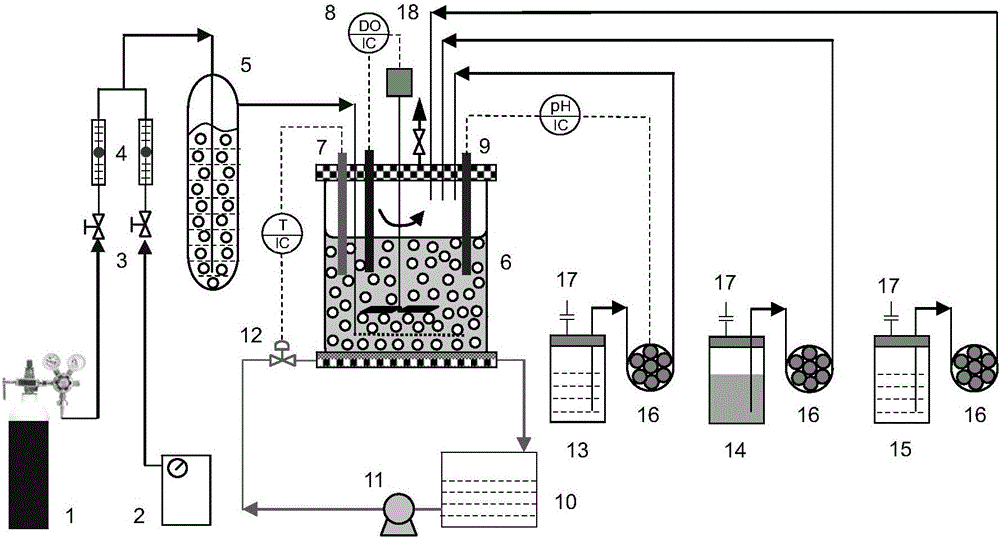

[0033] Batch fed-batch culture T. reesei RUT C30 production cellulase process as follows figure 1 shown. The oxygen from 1 in the oxygen cylinder and the air in the air compressor 2 are regulated by the regulating valve 3 and metered by the flow meter 4 to mix in an appropriate ratio and then enter the gas humidifier 5 for humidification, then pass into the fermenter 6, and The dissolved oxygen (DO) detection system 8 is linked to control the DO in the fermentation broth to not be less than 20%, so as to meet the requirements of mycelium growth and cellulase biosynthesis. The temperature detection system 7, the circulating water regulating valve 12, the circulating water tank 10 and the circulating water pump 11 form a temperature regulating control system. The pH detection system 9, the ammonia water storage tank 13 and the peristaltic pump 16 constitute a pH adjustment control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com