Production method of lithium ion battery separator paper

A technology of lithium-ion batteries and production methods, which is applied in pulp beating methods, battery components, paper, etc., can solve problems such as poor electrolyte affinity, battery fire, and poor dimensional stability, and achieve improved mechanical properties and durability. Effects of thermal performance, increased safety, thermal stability and improved wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

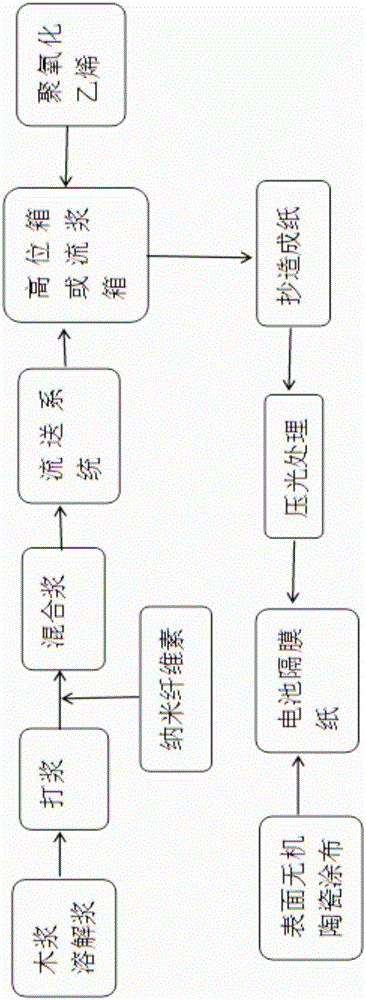

[0014] refer to figure 1 , which includes the following steps:

[0015] 1. Raw material preparation: the wood pulp is bleached coniferous wood pulp, and the wood pulp fiber with a length of about 3-5mm is processed by a beating process with a disc refiner. The preferred beating degree is about 50-60°SR. The addition of wood pulp is beneficial Paper machine performance needs. The dissolving pulp containing more than 90% of α-cellulose is treated with a disc refiner and beater, and the beating degree is preferably 50-60°SR. Its addition is convenient for paper drawing and can improve the oxidation resistance of the separator. The fineness of nanocellulose is about 0.1dtex to 0.3dtex.

[0016] 2. Mix wood pulp, dissolving pulp, and nanocellulose according to the mass ratio of 1:1:3, and send the uniformly mixed pulp into the flow delivery system, before the headbox or headbox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com