Nickel-cobalt double hydroxide/nitrogenous carbon nanohorn composite material used for supercapacitor and preparation method for composite material

A double hydroxide and supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of low product purity, difficult to control nitrogen content, and low nitrogen content in products, and achieve nitrogen The effect of rich content, good conductivity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

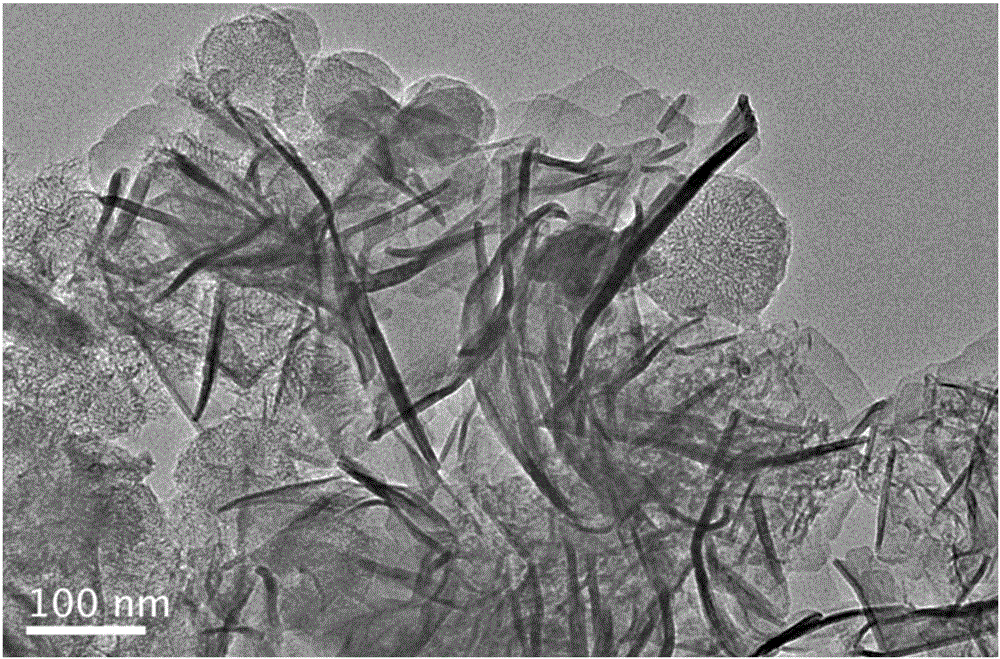

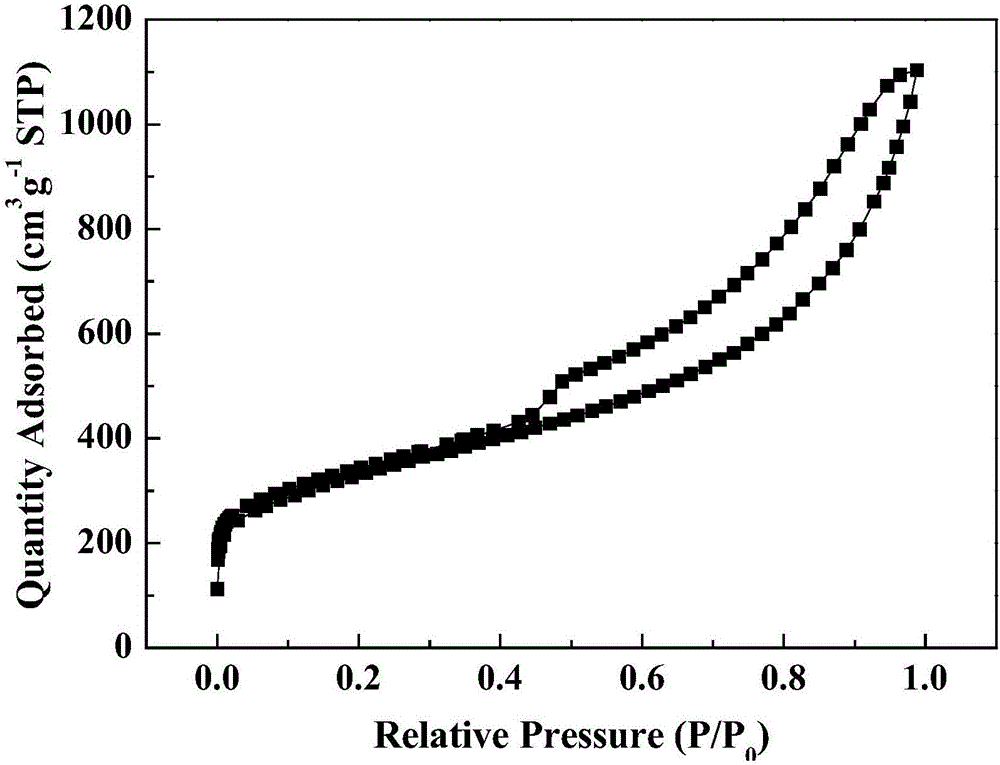

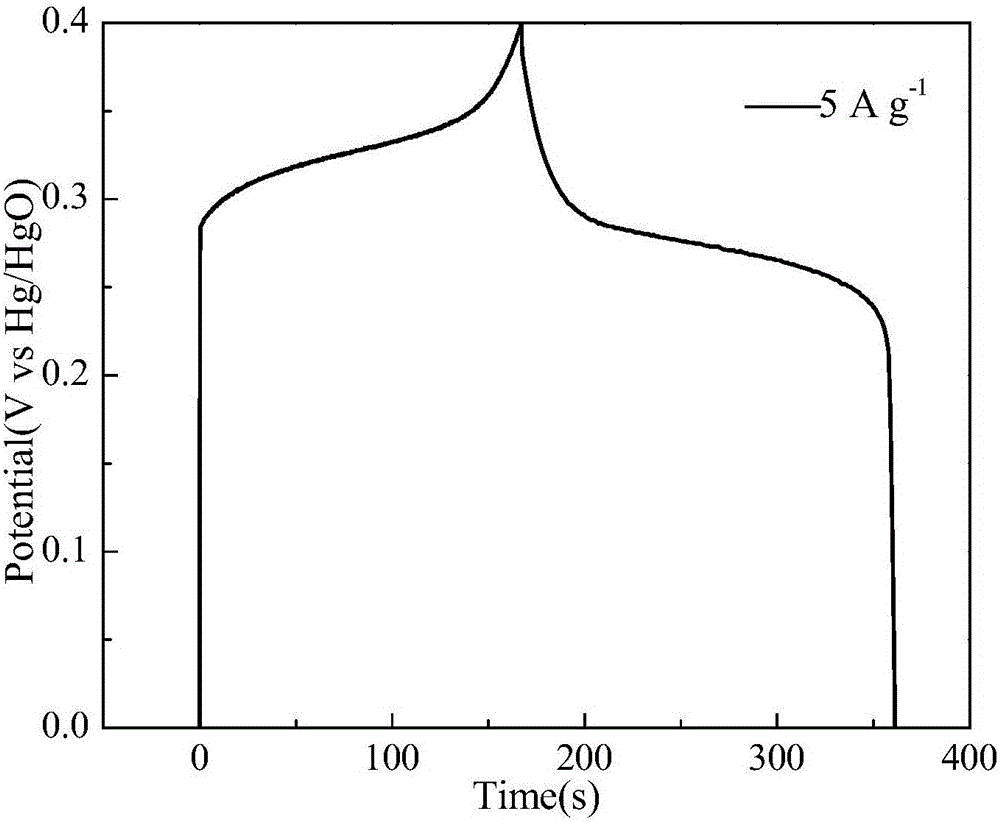

[0028] First, disperse 10g of high-purity graphite powder evenly into excess dicyandiamide aqueous solution, stir for 3 hours, then rotate the solvent at 60°C, then heat-treat at 1273K for 2 hours under an argon atmosphere, then wash with distilled water and filter And vacuum drying under 60 ℃, obtain nitrogen-containing graphite powder; Add sodium dodecylbenzenesulfonate and stir in this nitrogen-containing graphite powder again, and the mixing amount is 25% of nitrogen-containing graphite powder weight, will obtain The doped nitrogen-containing graphite powder was used as the cathode and the anode respectively, and was prepared by hydrogen arc method (current 500A, gas pressure 0.08MPa, volume ratio of helium and hydrogen 2:1) under the mixed atmosphere of helium and hydrogen. Solid product, then add 50mL of water and undergo ultrasonic oscillation, filtration, pickling, water washing and drying operations to obtain pure nitrogen-containing carbon nanohorns with a nitrogen co...

Embodiment 2

[0037] First, 10g of high-purity graphite powder was uniformly dispersed in dicyandiamide aqueous solution, stirred for 3h, then the solvent was evaporated at 60°C, and then heat-treated at 673K for 0.5h under an argon atmosphere, followed by distilled water washing, filtration and Vacuum drying at 60°C to obtain nitrogen-containing graphite powder. Then use the nitrogen-containing graphite powder as the cathode and anode respectively, under the mixed atmosphere of helium and hydrogen, adopt the hydrogen arc method (current 500A, gas pressure 0.08MPa, volume ratio of helium and hydrogen is 2:1) to prepare a solid product , and then add 50mL of water and undergo ultrasonic oscillation, filtration, pickling, water washing and drying operations to obtain pure nitrogen-containing carbon nanohorns with a nitrogen content of 1%; 0.1mol nickel nitrate and 0.4mol cobalt nitrate are dissolved in water -In the mixed solvent of ethanol (volume ratio 5:1), add 5 mol of the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com