Molybdenum selenide sulfide/carbon nanotube composite material, preparation and application thereof

A technology of carbon nanotubes and composite materials, which is applied in the direction of hybrid capacitor electrodes, electrical components, battery electrodes, etc., can solve the problems of poor semiconductor conductivity and limited applications, and achieve easy operation, inhibit agglomeration and stacking, and reduce Gibbs freedom Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

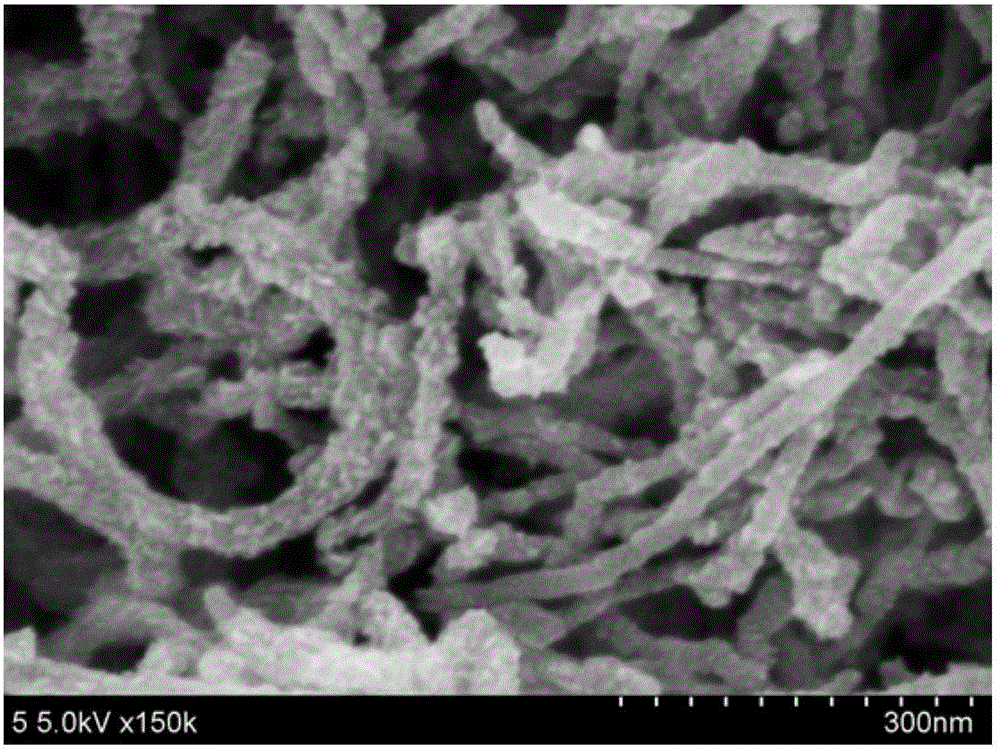

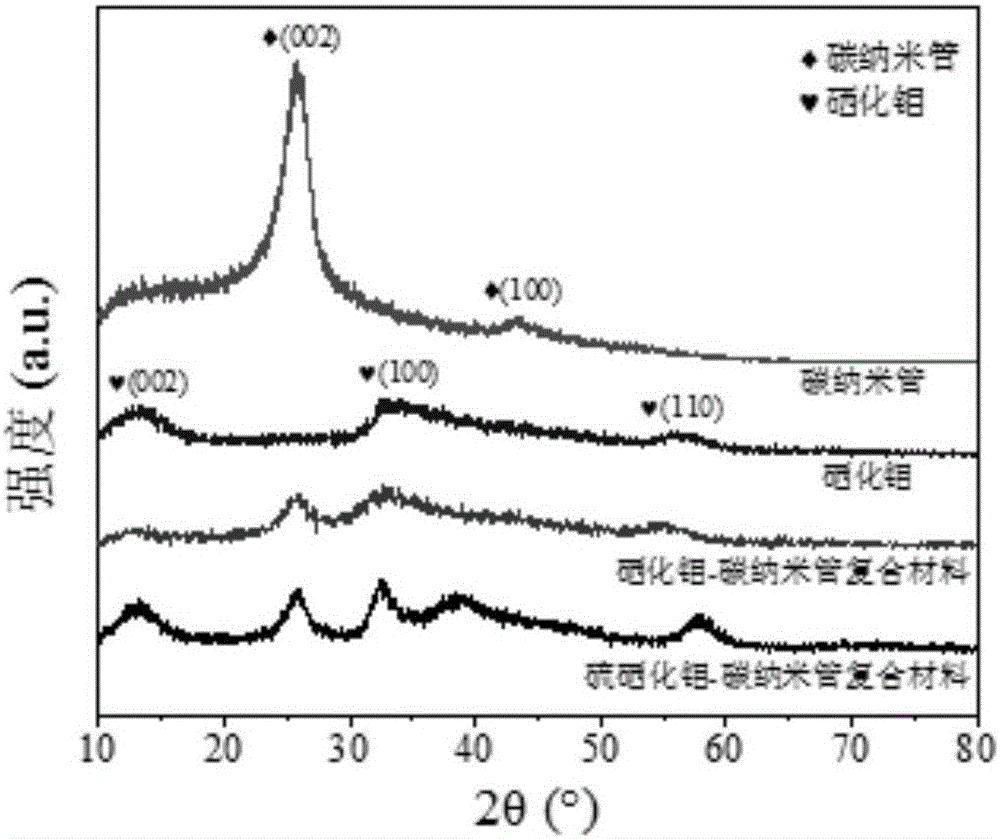

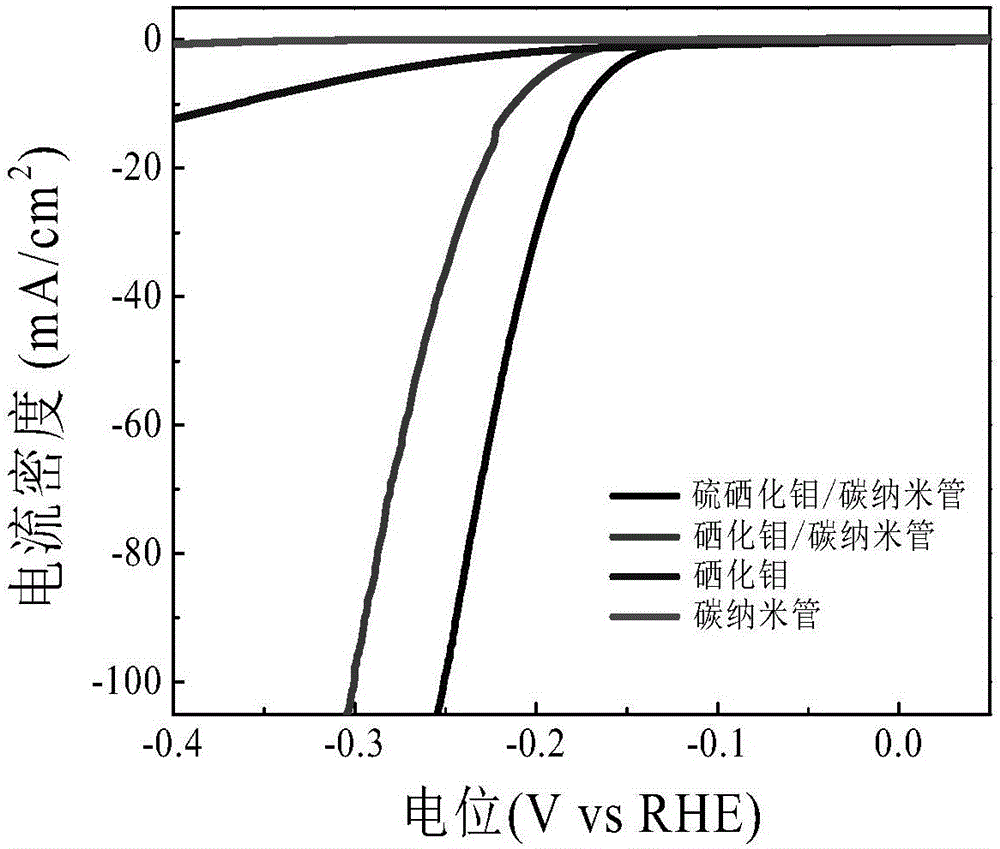

Embodiment 1

[0046] (1) Disperse 3 g of carbon nanotubes in 100 mL of concentrated sulfuric acid-concentrated nitric acid (volume ratio of 2:1) mixed solution, stir and react at 80°C for 8 hours to obtain an acid-treated carbon nanotube mixed acid solution;

[0047] (2) After the carbon nanotube mixed acid solution is cooled to room temperature, it is centrifuged, washed twice with deionized water and ethanol each, and dried in a vacuum oven at 50°C to obtain acid-treated carbon nanotube powder;

[0048] (3) Disperse 50 mg of acid-treated carbon nanotube powder in 25 mL of N,N-dimethylformamide and sonicate for a period of time to obtain an organic dispersion of carbon nanotubes;

[0049] (4) Dissolve 50 mg of selenium powder in 25 mL of hydrazine hydrate and stir for a period of time to make it evenly dispersed;

[0050] (5) Dissolve 76.61 mg of sodium molybdate in 0.2 mL of water, dissolve it fully by ultrasound and make it evenly dispersed;

[0051] (6) Pour the mixed solution containing carbon n...

Embodiment 2

[0055] (1) Disperse 3 g of carbon nanotubes in 100 mL of concentrated sulfuric acid-concentrated nitric acid (volume ratio of 2:1) mixed solution, stir and react at 80°C for 8 hours to obtain an acid-treated carbon nanotube mixed acid solution;

[0056] (2) After the carbon nanotube mixed acid solution is cooled to room temperature, it is centrifuged, washed twice with deionized water and ethanol each, and dried in a vacuum oven at 50°C to obtain acid-treated carbon nanotube powder;

[0057] (3) Disperse 50 mg of acid-treated carbon nanotube powder in 25 mL of N,N-dimethylformamide and sonicate for a period of time to obtain an organic dispersion of carbon nanotubes;

[0058] (4) Dissolve 50 mg of selenium powder in 25 mL of hydrazine hydrate and stir for a period of time to make it evenly dispersed;

[0059] (5) Dissolve 76.61 mg of sodium molybdate in 0.2 mL of water, dissolve it fully by ultrasound and make it evenly dispersed;

[0060] (6) Pour the mixed solution containing carbon n...

Embodiment 3

[0064] (1) Disperse 3 g of carbon nanotubes in 100 mL of concentrated sulfuric acid-concentrated nitric acid (volume ratio of 2:1) mixed solution, stir and react at 80°C for 8 hours to obtain an acid-treated carbon nanotube mixed acid solution;

[0065] (2) After the carbon nanotube mixed acid solution is cooled to room temperature, it is centrifuged, washed twice with deionized water and ethanol each, and dried in a vacuum oven at 50°C to obtain acid-treated carbon nanotube powder;

[0066] (3) Disperse 50 mg of acid-treated carbon nanotube powder in 25 mL of N,N-dimethylformamide and sonicate for a period of time to obtain an organic dispersion of carbon nanotubes;

[0067] (4) Dissolve 50 mg of selenium powder in 25 mL of hydrazine hydrate and stir for a period of time to make it evenly dispersed;

[0068] (5) Dissolve 76.61 mg of sodium molybdate in 0.2 mL of water, dissolve it fully by ultrasound and make it evenly dispersed;

[0069] (6) Pour the mixed solution containing carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com