Compound cyanide-free gold plating solution and preparation method thereof

A cyanide-free gold plating and gold salt technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of nickel layer corrosion, unstable, poor plating effect, etc. The effect of low efficiency and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

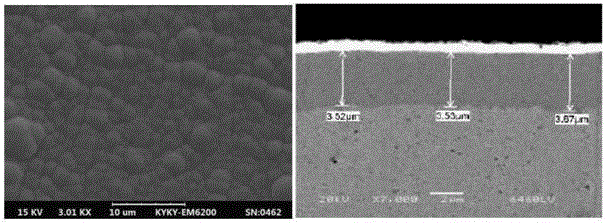

Embodiment 1

[0043]A kind of composite cyanide-free gold plating solution of the present embodiment is made of sodium gold sulfite, ethylene thiourea, sodium sulfamate, ammonium citrate, anhydrous sodium sulfite, hydroxyethylidene diphosphonic acid, sodium ascorbate, phosphoric acid Sodium dihydrogen, disodium hydrogen phosphate and water.

[0044] Wherein, in the compound cyanide-free gold plating solution, the content of sodium gold sulfite is 2.5g / L, the content of ethylenethiourea is 20g / L, the content of sodium sulfamate is 10g / L, ammonium citrate 5g / L, the content of anhydrous sodium sulfite is 2g / L, the content of hydroxyethylidene diphosphonic acid is 8g / L, the content of sodium ascorbate is 10g / L, the content of sodium dihydrogen phosphate is 12g / L, dihydrogen phosphate The content of sodium is 5g / L.

[0045] Wherein, the pH buffering agent sodium dihydrogen phosphate and disodium hydrogen phosphate make the pH value of the compound cyanide-free gold plating solution be controlle...

Embodiment 2

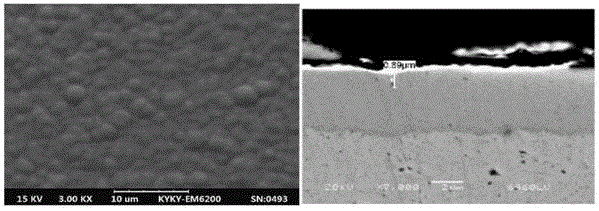

[0051] A kind of composite cyanide-free gold plating solution of the present embodiment is made of sodium gold sulfite, 2-amino-5-mercapto-1,3,4 thiazole, tetraethylene pentamine, melamine, sodium hypophosphite, amino trisulfite Methylphosphonic acid, diethyltriaminepentaacetic acid, carmine, sodium dihydrogen phosphate, disodium hydrogen phosphate and water.

[0052] Wherein, in the compound cyanide-free gold plating solution, the content of sodium gold sulfite is 2.5g / L, the content of 2-amino-5-mercapto-1,3,4thiazole is 10g / L, tetraethylene penta The content of amine is 8g / L, the content of melamine is 3g / L, the content of sodium hypophosphite is 1.5g / L, the content of aminotrimethylene phosphonic acid is 2g / L, and the content of diethyltriaminepentaacetic acid is 3g / L, the content of carmine is 1g / L, the content of sodium dihydrogen phosphate is 15g / L, and the content of disodium hydrogen phosphate is 5g / L.

[0053] Wherein, the pH buffer agent sodium dihydrogen phosphate...

Embodiment 3

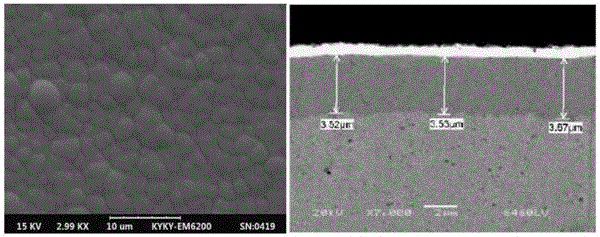

[0059] A kind of composite cyanide-free gold plating solution of the present embodiment is made of sodium gold sulfite, 6-mercaptopurine, thiosemicarbazide, potassium sulfamate, potassium pyrophosphate, sodium hypophosphite, hydroxyethylidene diphosphonic acid, D - Composed of sorbitol, disodium dihydrogen pyrophosphate and water.

[0060] Wherein, in this composite cyanide-free gold plating solution, the content of sodium gold sulfite is 2.5g / L, the content of 6-mercaptopurine is 15g / L, the content of thiosemicarbazide is 10g / L, the content of potassium sulfamate The content is 5g / L, the content of potassium pyrophosphate is 5g / L, the content of sodium hypophosphite is 1.5g / L, the content of hydroxyethylidene diphosphonic acid is 20g / L, and the content of D-sorbitol is 8g / L L, the content of disodium dihydrogen pyrophosphate is 10g / L.

[0061] Wherein, the pH buffer agent disodium dihydrogen pyrophosphate makes the pH value of the compound cyanide-free gold plating solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com