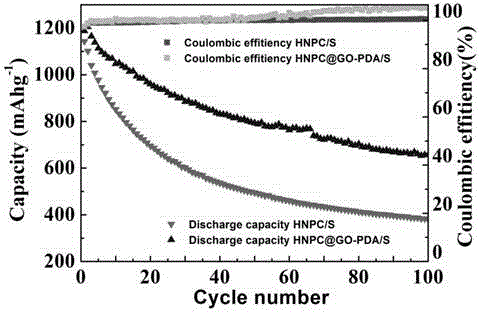

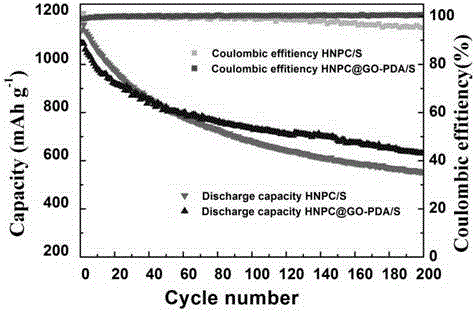

Research of surface-modified nitrogen-doped porous carbon-sulfur composite material in positive electrode of lithium-sulfur battery

A technology of nitrogen-doped porous carbon and composite materials, applied in battery electrodes, lithium batteries, nanotechnology for materials and surface science, etc., can solve problems such as loss of active materials, short life of electrodes, and theoretical capacity limitations. Achieve the effects of alleviating the volume expansion problem, stabilizing the material structure, and improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

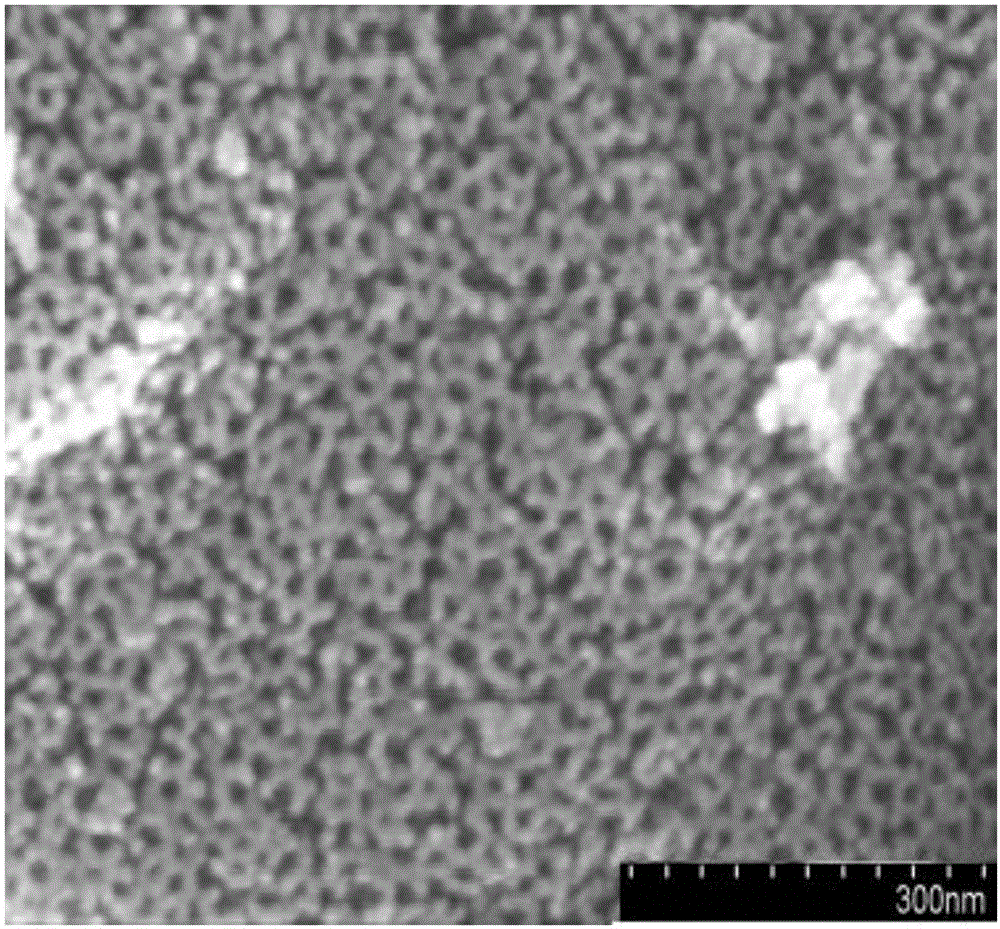

[0026] (1) Dissolve 4g of o-phenylenediamine in 2mol / L hydrochloric acid solution, ultrasonically disperse it evenly, then add 10g of nano-silica ball hard template in turn, and add 20mL of 1mol / L ammonium persulfate aqueous solution under stirring , and using an ice-water bath to maintain the temperature at 0°C for 24 hours of polymerization, then centrifuged and dried to obtain a solid product.

[0027] (2) Under the protection of nitrogen, the solid product was heated up to 900°C at 10°C / min and calcined for 1 hour, and then cooled down to room temperature naturally.

[0028] (3) Add the above solid to 4 mol / L ammonium bifluoride aqueous solution to etch the silica nanospheres, stir at room temperature for 24 hours, wash with deionized water, and dry at 80°C for 12 hours to obtain a nitrogen-doped porous carbon material solid product.

[0029] (4) After mixing and grinding the nitrogen-doped porous carbon material and elemental sulfur, heat treatment at 160-200° C. under t...

Embodiment 2

[0032] (1) Dissolve 4g of o-phenylenediamine in 2mol / L hydrochloric acid solution, ultrasonically disperse it evenly, then add 10g of nano-silica ball hard template in turn, and add 20mL of 1mol / L ammonium persulfate aqueous solution under stirring , and using an ice-water bath to maintain the temperature at 0°C for 24 hours of polymerization, then centrifuged and dried to obtain a solid product.

[0033] (2) Under the protection of nitrogen, the solid product was heated up to 900°C at 10°C / min and calcined for 1 hour, and then cooled down to room temperature naturally.

[0034] (3) The above solid was added to 4 mol / L ammonium bifluoride aqueous solution to etch the silica nanospheres, stirred at room temperature for 24 h, washed with deionized water, and dried at 80° C. for 12 h.

[0035] (4) The obtained solid was calcined at 5° C. / min to 900° C. for 60 minutes under the condition of ammonia gas, and then naturally lowered to room temperature to obtain an activated nitrogen...

Embodiment 3

[0039] (1) Dissolve 4g of o-phenylenediamine in 2mol / L hydrochloric acid solution, ultrasonically disperse it evenly, then add 10g of silica ball hard template in turn, add 20mL of 1mol / L ammonium persulfate aqueous solution under stirring, And use an ice-water bath to keep the temperature at 0°C for 24 hours of polymerization, then centrifuge and dry to obtain a solid product.

[0040] (2) The solid product was calcined at a rate of 10° C. / min to 900° C. for 1 h under the protection of nitrogen, and then naturally cooled to room temperature.

[0041] (3) The above solid was added to 4 mol / L ammonium bifluoride aqueous solution to etch the silica nanospheres, stirred at room temperature for 24 h, washed with deionized water, and dried at 80° C. for 12 h.

[0042] (4) The obtained solid was calcined at 5° C. / min to 900° C. for 60 minutes under the condition of ammonia gas, and then naturally lowered to room temperature to obtain an activated nitrogen-doped connected porous carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com