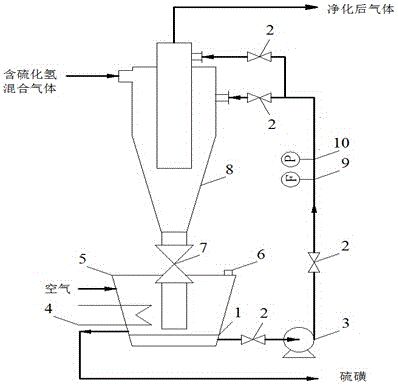

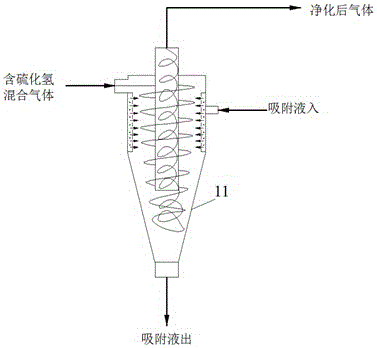

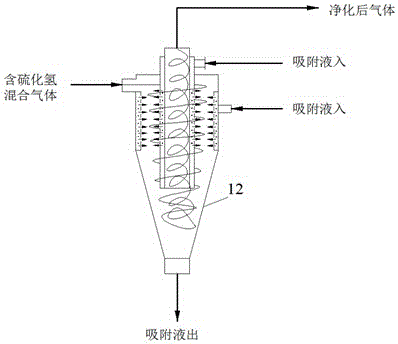

High-efficiency hydrogen sulfide gas absorption device

A gas absorption and hydrogen sulfide technology, applied in gas treatment, combined devices, chemical recovery, etc., can solve the problems of multiple components, high operating costs, and large equipment, and achieve the effects of easy integration, high desulfurization efficiency, and complete regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Removal of hydrogen sulfide from industrial gas: the gas volume to be treated in the process is 15000m 3 / h, hydrogen sulfide content is 1600mg / m 3 , to prepare 140 m of desulfurization adsorption solution 3 .

[0051] Turn on the device, and after the device stabilizes (about 5 minutes), turn on the circulation pump and adjust the liquid volume to 100m 3 / h, after the liquid phase runs stably, open the gas phase, and gradually reach 15000m through the regulating valve 3 / h. The gas and liquid are absorbed in the device under the conditions of high turbulence, strong mixing, and extremely fast interface renewal. After the entire system is stabilized, the hydrogen sulfide content can be detected at the gas inlet and outlet.

[0052] Technical effect: Due to the use of swirling jet adsorbers to recover hydrogen sulfide, the efficiency of each stage is above 99%, and the overall efficiency is above 95%, which greatly improves the hydrogen sulfide removal effect and pro...

Embodiment 2

[0054] Remove hydrogen sulfide in natural gas, the volume of natural gas is 15000m 3 / h, the hydrogen sulfide concentration is 2400mg / m 3 .

[0055] Technical effect:

[0056] The operation process is as in Example 1. After the system is stabilized, the removal rate of hydrogen sulfide can reach more than 97%, and the outlet concentration of hydrogen sulfide is lower than 50mg / m 3 , compared with the traditional wet process, the equipment volume is less than 1 / 10 of the tower equipment, and the liquid circulation volume is reduced by 60%.

Embodiment 3

[0058] Selective absorption of hydrogen sulfide in acidic systems in industrial syngas (CO 2 The volume content accounts for 96.6%, the volume content of hydrogen sulfide accounts for 0.78%, and the concentration is 10.6g / m 3 ), the gas volume to be treated in the process is 28000m 3 / h, hydrogen sulfide content is 10200mg / m 3 . First prepare the desulfurization adsorption liquid, the liquid volume is 300 m 3 / h. According to the short residence time of the cyclone adsorber, the absorption of hydrogen sulfide by the desulfurization adsorption liquid is completed in an instant, thereby improving the selectivity of absorption, reducing side reactions, and reducing alkali consumption; after the system is stable, hydrogen sulfide is removed The rate can reach more than 94%, CO 2 Concentration import and export changes less than 0.3%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com