Preparation method and application of oxidized graphene and magnetic chitosan compound

A technology of chitosan and graphene, which is applied in the field of biological adsorption materials and water treatment, can solve the problem of the reduction of magnetic chitosan adsorption capacity, etc., and achieve the effect of simple and easy operation, large-scale industrial production and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

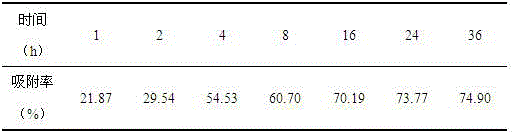

Examples

Embodiment 1

[0026] A preparation method of graphene oxide and magnetic chitosan composite, comprising the following steps:

[0027] Step 1, at room temperature, 1.2536g of FeCl 2 4H 2 O and 3.4624g FeCl 3 ·6H 2 Dissolve O in 50ml of ultrapure water, then add it dropwise to 200ml of ultrapure water containing 8ml of ammonia water (the concentration of ammonia water is 25%), keep stirring at 90°C for 180min, let the solution cool to room temperature, and magnetically separate The precipitate was obtained, and then washed with ultrapure water until neutral, and finally the precipitate was vacuum-dried at a temperature of 60°C to obtain magnetic particles;

[0028] Step 2. At room temperature, dissolve 0.9g of chitosan in 90ml of acetic acid (the concentration of acetic acid is 3%) solution, then ultrasonically disperse 0.3g of the magnetic particles in step 1 in the above solution, and then add 1ml of glutaraldehyde (glutaraldehyde concentration is 25%) solution, and continuously stirred...

Embodiment 2

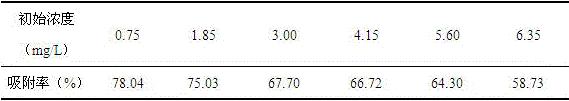

[0031] The graphene oxide and magnetic chitosan compound prepared in embodiment 1 are applied to the removal of triclosan wastewater, comprising the following steps: first configure the initial concentration of 0.75, 1.85, 3.00, 4.15, 5.60 and 6.35mg / L 6 groups of triclosan solutions, 25ml of each group of samples, adjusting the pH of the solution to 6.5, adding the compound prepared in Example 1, the dosage of the compound is 0.28g / L, and carrying out the adsorption reaction in a rotary incubator, The rotational speed was 7 rpm, and after 36 hours, the compound was separated from the wastewater by applying an external magnetic field. The content of unadsorbed triclosan in wastewater was detected by high-performance liquid chromatography ultraviolet detector (HPLC). The model was Watets2695, and the chromatographic column model (4.6×150 mm Bridge-C18). The detection method: the mobile phase was water-acetonitrile (25:75; v:v), flow rate 1.0 mL / min, column temperature 30°C, inj...

Embodiment 3

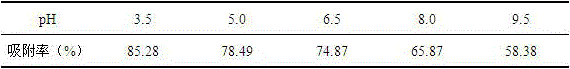

[0036] The graphene oxide and magnetic chitosan compound prepared in embodiment 1 are applied to the removal of triclosan wastewater, comprising the following steps: first configure 5 groups of 25ml, the concentration is the triclosan solution of 1.85mg / L, adjust the solution The pH is 3.5, 5.0, 6.5, 8.0, 9.5, adding the complex prepared in Example 1, the dosage of the complex is 0.28g / L, and the adsorption reaction is carried out in a rotary incubator with a rotating speed of 7rpm. After 36h The complexes are separated from the wastewater by means of an external magnetic field. The content of unadsorbed triclosan in wastewater was detected by high performance liquid chromatography with ultraviolet detector (HPLC).

[0037] The adsorption efficiency of the complex to triclosan was measured at different pH values, as shown in Table 2 below. It can be seen from the table that when the pH of the solution is 3.5, the degradation rate is 85.28%, and when the pH of the solution is 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com