Integral DOC catalyst for marine diesel engine tail gas purification and preparation process thereof

A marine diesel engine and exhaust gas purification technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high sulfate content, achieve high catalytic activity, Strong aging resistance and uniform coating distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

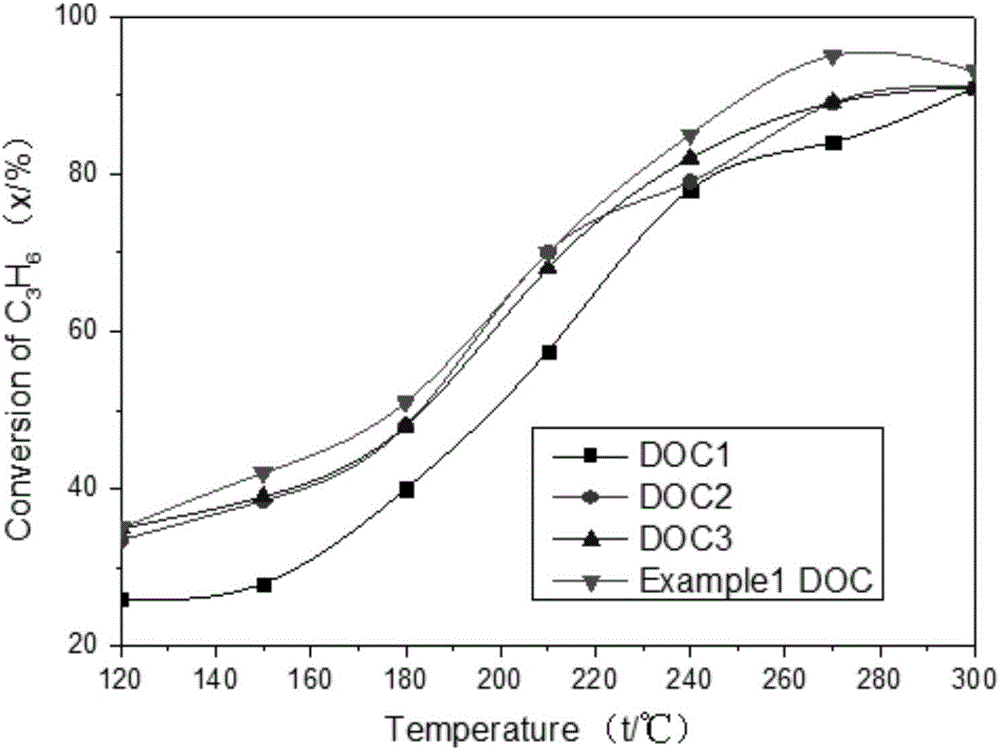

[0039] Embodiment 1 Preparation containing cerium-palladium DOC catalyst

[0040] A preparation process for an integral DOC catalyst for marine diesel engine tail gas purification, the specific steps of the process are as follows:

[0041] 1) Pretreatment: Soak the cordierite honeycomb ceramic carrier in 20%wt oxalic acid solution at 60°C for 3 hours.

[0042] 2) Preparation of active component slurry:

[0043] The formulation of the active ingredient paste is:

[0044] Pseudoboehmite (calculated by alumina mass) accounting for 9%wt of the slurry, cerium oxide powder accounting for 2.7%wt of the slurry, urea accounting for 2.25%wt of the slurry, palladium (Pd) accounting for 1.5%wt of the slurry );

[0045] Nitric acid, the addition of nitric acid is to make the amount of hydrogen ion material reach 8% of pseudo-boehmite, even if n(H+) / n(Al)=0.08 in the slurry;

[0046] Account for the citric acid of slurry 3%wt;

[0047] The remaining components are deionized water;

[...

Embodiment 2

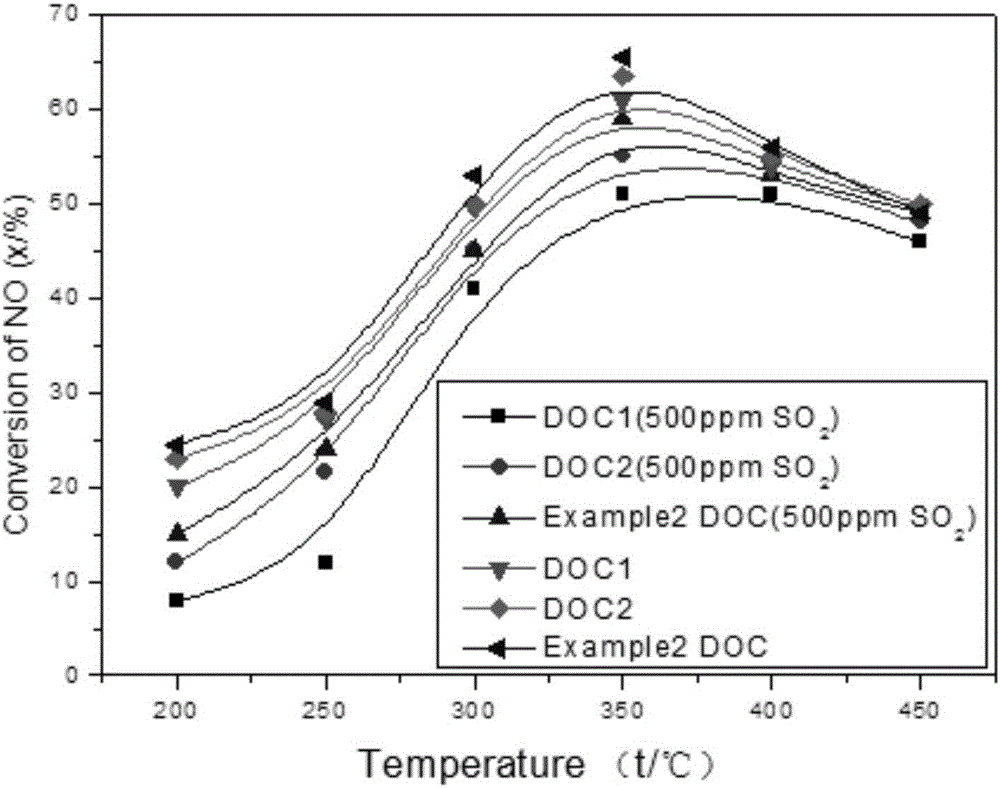

[0063] Example 2 Preparation of DOC catalyst containing cerium-zirconium-palladium:

[0064] A preparation process for an integral DOC catalyst for marine diesel engine tail gas purification, the specific steps of the process are as follows:

[0065] 1) Pretreatment: Soak the cordierite honeycomb ceramic carrier in 20%wt oxalic acid solution at 60°C for 3 hours.

[0066] 2) Preparation of active component slurry:

[0067] The formulation of the active ingredient paste is:

[0068] Pseudoboehmite (calculated by alumina mass) accounting for 9%wt of slurry, cerium oxide and 0.81%wt of zirconia powder accounting for 2.7%wt of the total mass of slurry, urea accounting for 2.25%wt of slurry, accounting for Palladium (Pd) of slurry 1.5%wt;

[0069] Nitric acid, the addition of nitric acid is to make the amount of hydrogen ion material reach 8% of pseudo-boehmite, even if n(H+) / n(Al)=0.08 in the slurry;

[0070] Attapulgite accounting for 1%wt of slurry;

[0071] The remaining co...

Embodiment 3

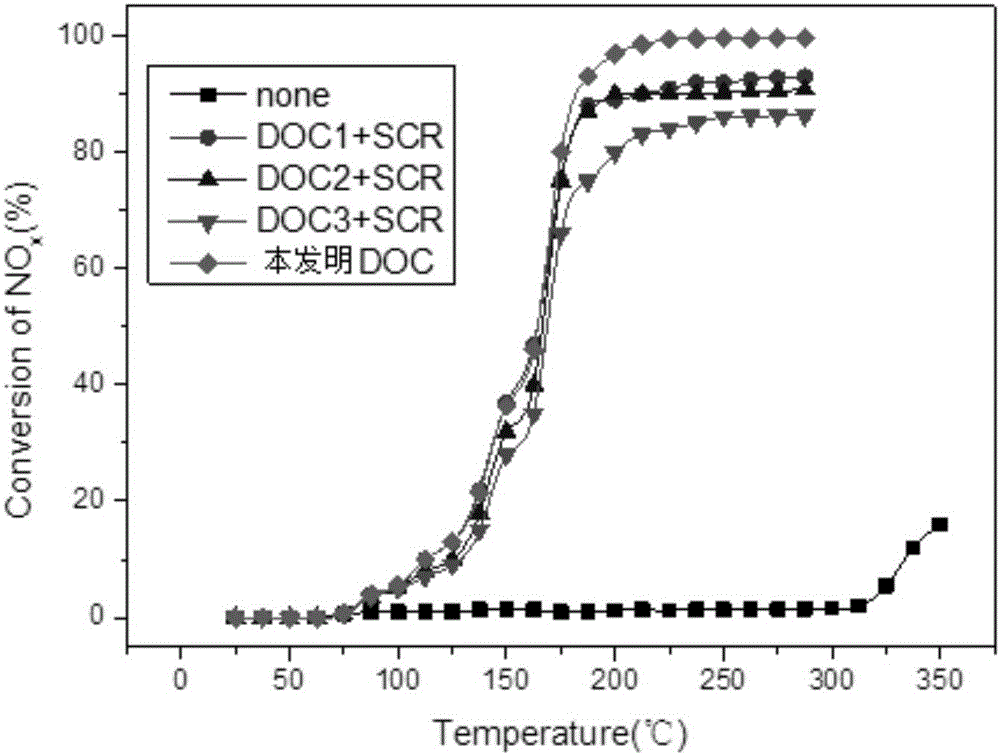

[0082] A monolithic DOC catalyst for exhaust purification of marine diesel engines, the catalyst uses cordierite honeycomb ceramics as a carrier, and the mass of cordierite honeycomb ceramics is 100%, and the content of active components loaded on the cordierite honeycomb ceramic carrier is : 3.5% palladium, 5.5% cerium oxide, 1% zirconia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com