A method for simultaneously producing pure hydrogen and pure carbon monoxide by gasification without desorption and absorption gas circulation

A carbon monoxide and gas desorption technology, applied in the direction of carbon monoxide, chemical instruments and methods, gasification process, etc., can solve the problems of increasing equipment investment and compressor operation power consumption, etc., to reduce equipment investment and operating costs, low investment, The effect of reducing the amount of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

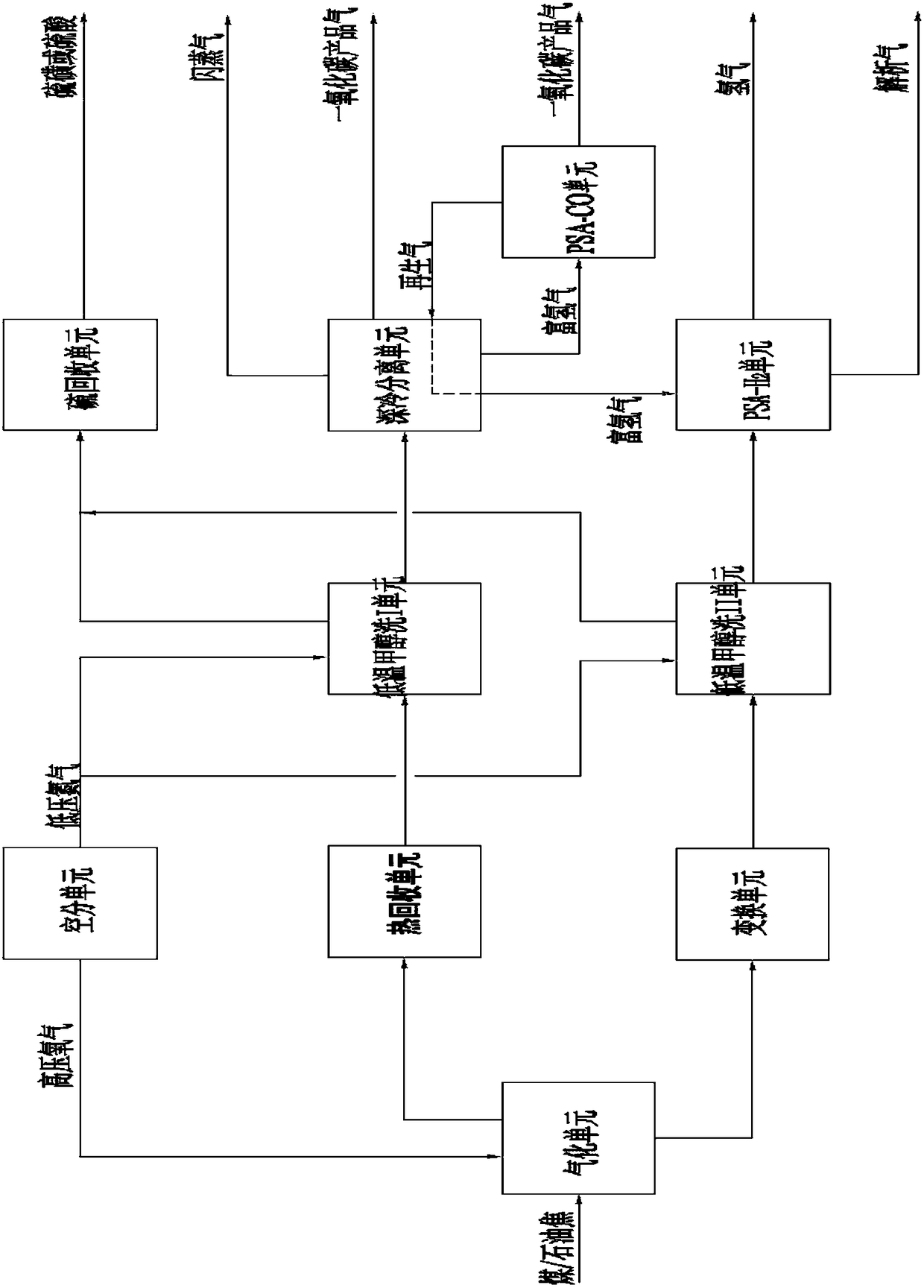

[0032] Such as figure 1 As shown, below in conjunction with technical scheme and accompanying drawing, take hydrogen and carbon monoxide required for 200,000 tons / year ethylene glycol as an example, describe the specific embodiment of the present invention in detail. The hydrogen volume corresponding to the 200,000 tons / year ethylene glycol plant is 40900Nm 3 / h, the amount of carbon monoxide is 20600Nm 3 / h.

[0033] (1) Gasification unit

[0034] Using coal as raw material, using coal water slurry gasification to produce synthesis gas 82270Nm 3 / h (dry basis), the pressure is 4.3MPaG, the temperature is 218°C, the effective gas H in the syngas 2 +CO is 65686Nm 3 / h, the synthesis gas is divided into two streams: one stream goes to the heat recovery unit, and the other stream goes to the conversion unit.

[0035] (2) Heat recovery unit

[0036] The crude synthesis gas from the gasification unit accounts for about 40-60% of the total crude synthesis gas produced by gasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com