Preparation method of quaternary ammonium cationic starch flocculant prepared by dmso/h2o/naoh system

A technology of quaternary ammonium salt cation and flocculant is applied in the field of preparing quaternary ammonium salt cationic starch flocculant in DMSO/H2O/NaOH system, which can solve the problem of low substitution degree, poor hydrophilicity and poor flocculation effect of quaternary ammonium salt cationic starch flocculant. and other problems, to achieve the effect of shortening the total reaction time, improving the reaction efficiency, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

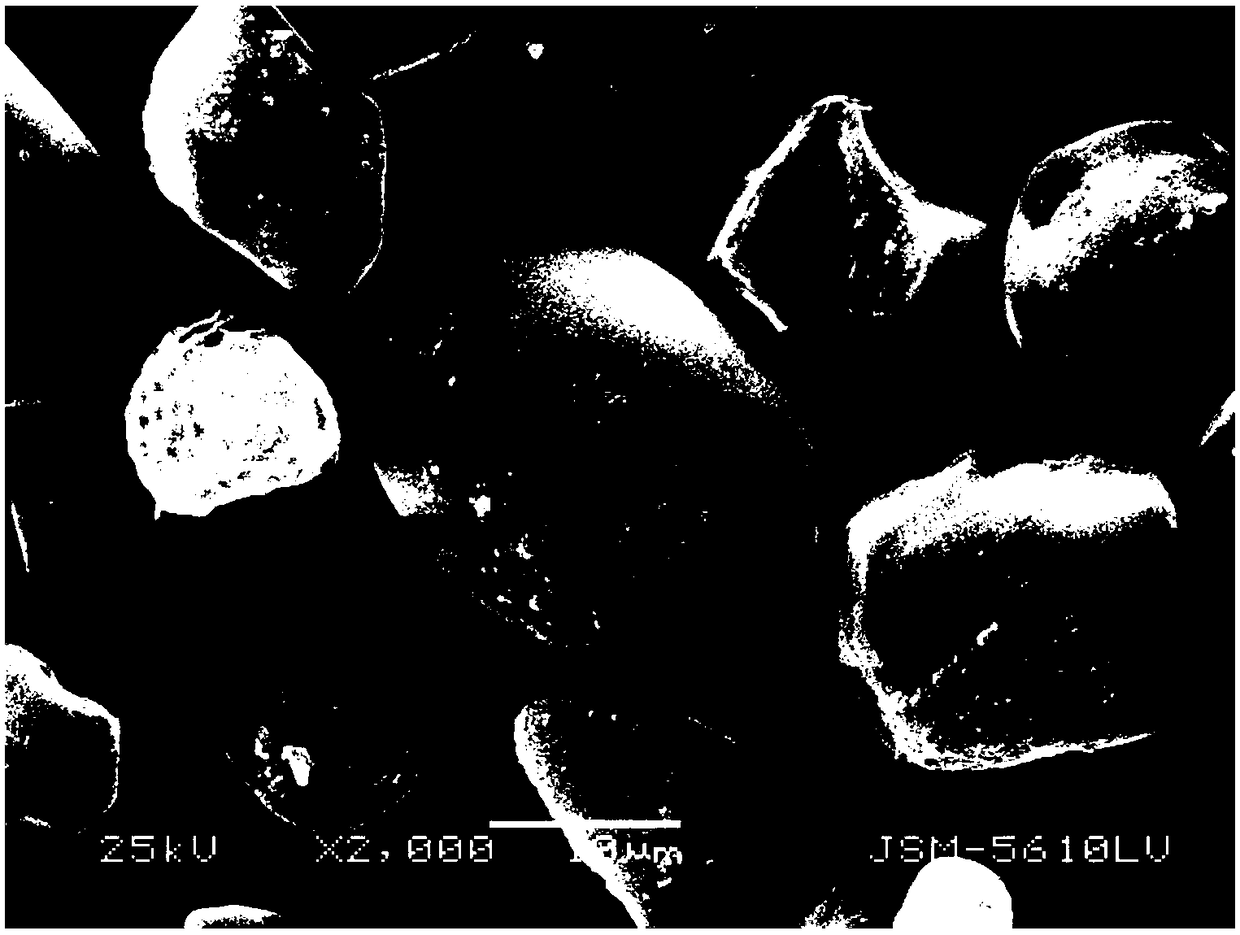

Embodiment 1

[0027] Dissolve 0.27g of sodium hydroxide in 13g of water. After the solid sodium hydroxide is completely dissolved, add 100g of dimethyl sulfoxide and 10g of absolute dry cornstarch, heat and stir at 85°C and react for 1h under reflux conditions to obtain starch activation solution. Get 9.2g of 3-chloro-2-hydroxypropyltrimethylammonium chloride solution (60%) and 4.87g of sodium hydroxide solution (40%) in the ice-water bath after activating for 5 minutes and immediately add to the starch cooled to 60°C In the activation solution, stirred at 500 rpm, reacted at 60°C for 1 hour, cooled to room temperature, extracted the crude product with ethanol, dried under reduced pressure, extracted twice with ethanol-glacial acetic acid mixed solution, dried to constant weight to obtain a white powder It is a quaternary ammonium salt cationic starch flocculant with a measured degree of substitution of 0.154, which can be well dissolved in cold water to form a transparent solution and has ...

Embodiment 2

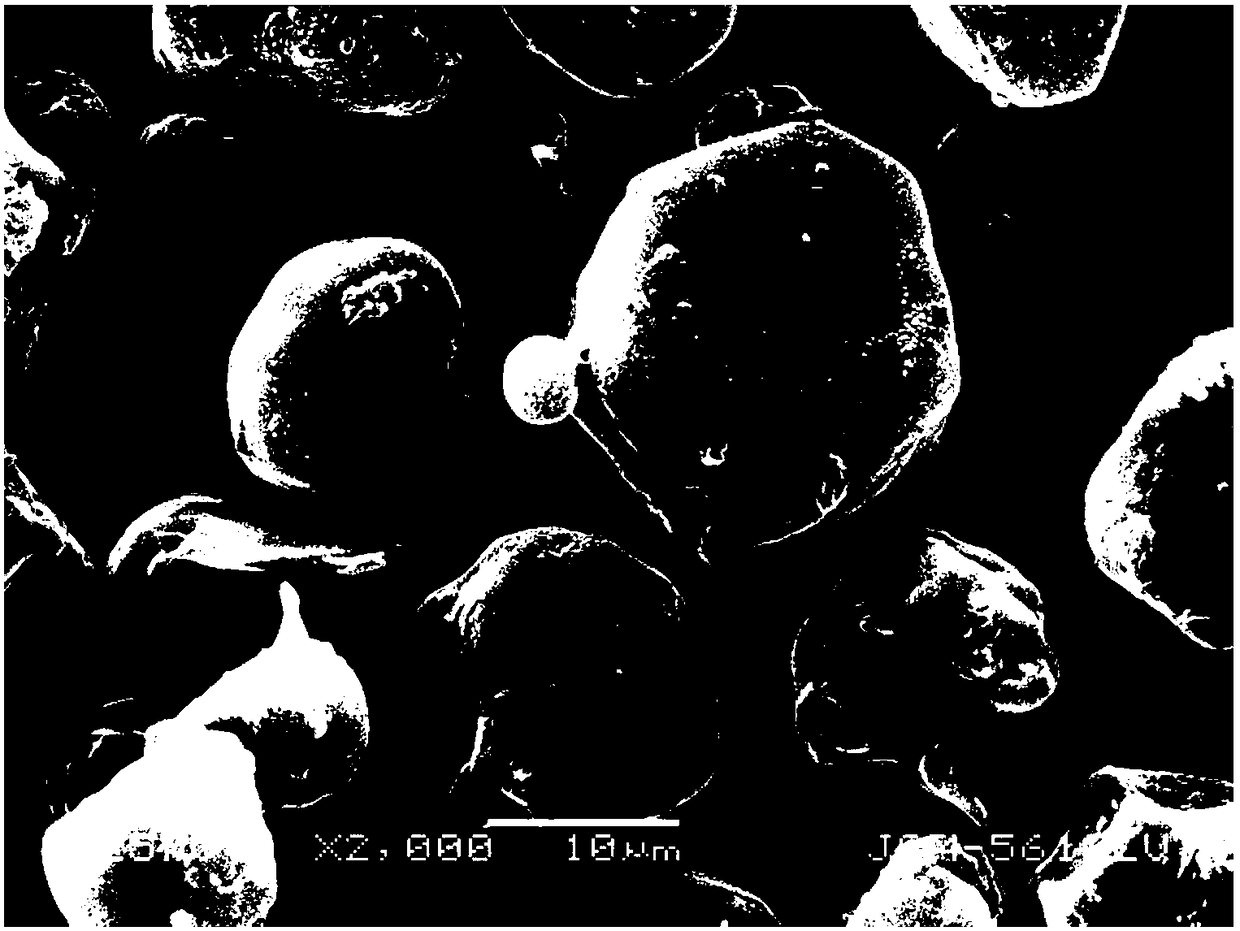

[0029] Dissolve 0.20g of sodium hydroxide in 10g of water, add 100g of dimethyl sulfoxide and 10g of absolute dry cornstarch to it after the solid sodium hydroxide is completely dissolved, heat and stir at 105°C and condense and reflux for 1 hour, Obtain starch activation solution. Get 10.0g of 3-chloro-2-hydroxypropyltrimethylammonium chloride solution (60%) and 10.0g of sodium hydroxide solution (20%) in an ice-water bath for 3 minutes after activation and immediately add to cool to 70°C In the starch activation solution, stirred at 800 rpm, reacted at 70°C for 0.8h, cooled to room temperature, extracted the crude product with ethanol, dried under reduced pressure, extracted twice with ethanol-glacial acetic acid mixed solution, and dried to constant weight The quaternary ammonium salt cationic starch flocculant in the form of white powder was obtained, and its degree of substitution was measured to be 0.167, which can be dissolved in cold water to form a transparent solutio...

Embodiment 3

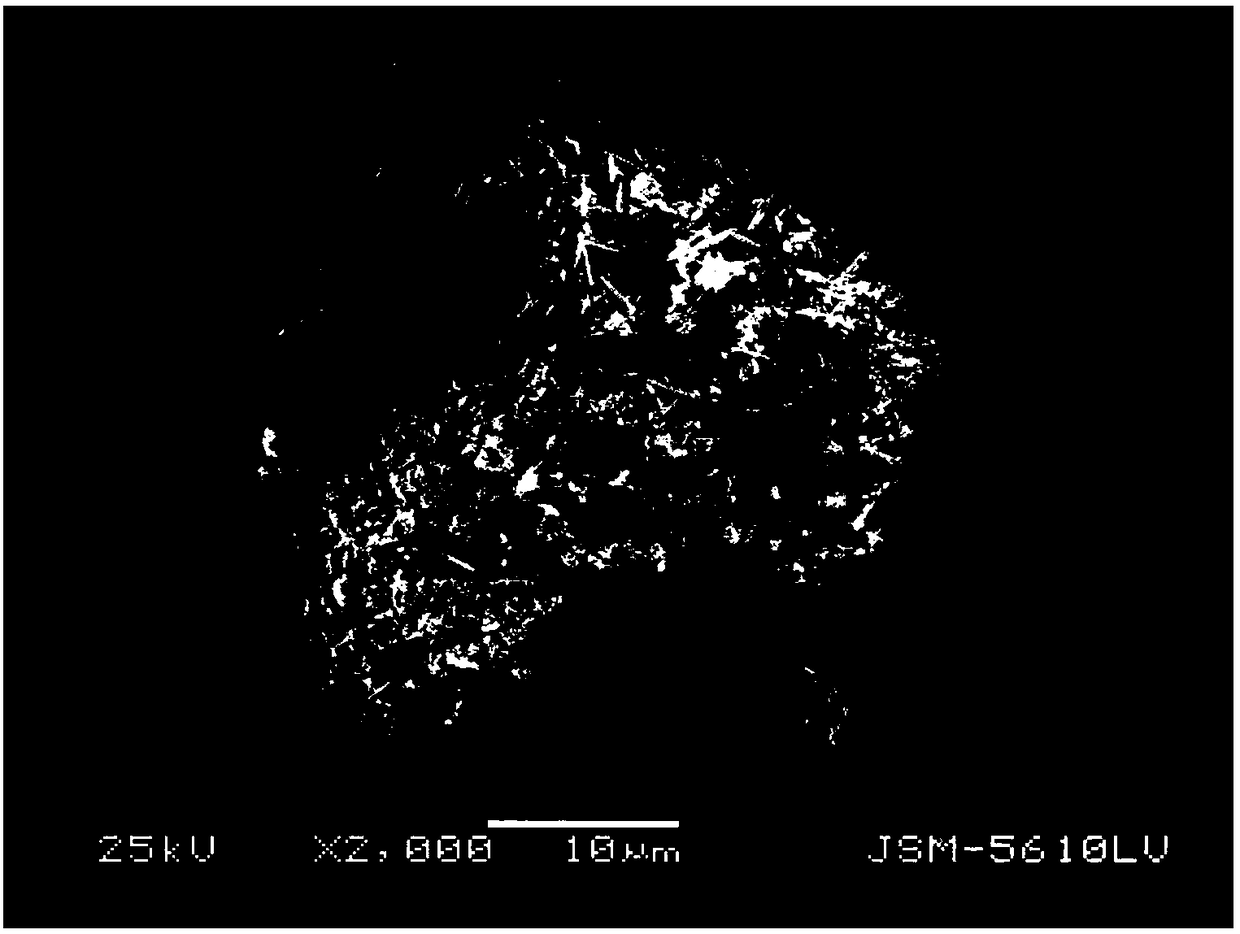

[0031] Dissolve 0.13g of sodium hydroxide in 6.5g of water. After the solid sodium hydroxide is completely dissolved, add 100g of dimethyl sulfoxide solution and 10g of dry cornstarch to it, heat and stir at 115°C and condense and reflux for 0.8 After h, the starch activation solution was obtained. Get 10.0g of 3-chloro-2-hydroxypropyltrimethylammonium chloride powder and 20.0g of sodium hydroxide solution (15%), activate it in an ice-water bath for 3 minutes, and immediately add it to the starch activation solution cooled to 75°C , stirred at 500 rpm, reacted at 75°C for 1 h, cooled to room temperature, extracted the crude product with ethanol, dried under reduced pressure and extracted 3 times with a mixed solution of ethanol-glacial acetic acid, dried to constant weight to obtain white powder The quaternary ammonium salt cationic starch flocculant has a degree of substitution of 0.254. It can be well dissolved in cold water to form a transparent solution and has a good floc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com