High-nickel austenite nodular cast iron and production technique for same

A nodular cast iron and production process technology, applied in the field of nodular cast iron, can solve problems such as large whitening tendency of molten iron, poor fluidity of molten iron, unqualified nodularization grade, etc., achieve uniform structure and performance, strengthen matrix structure, and reduce internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

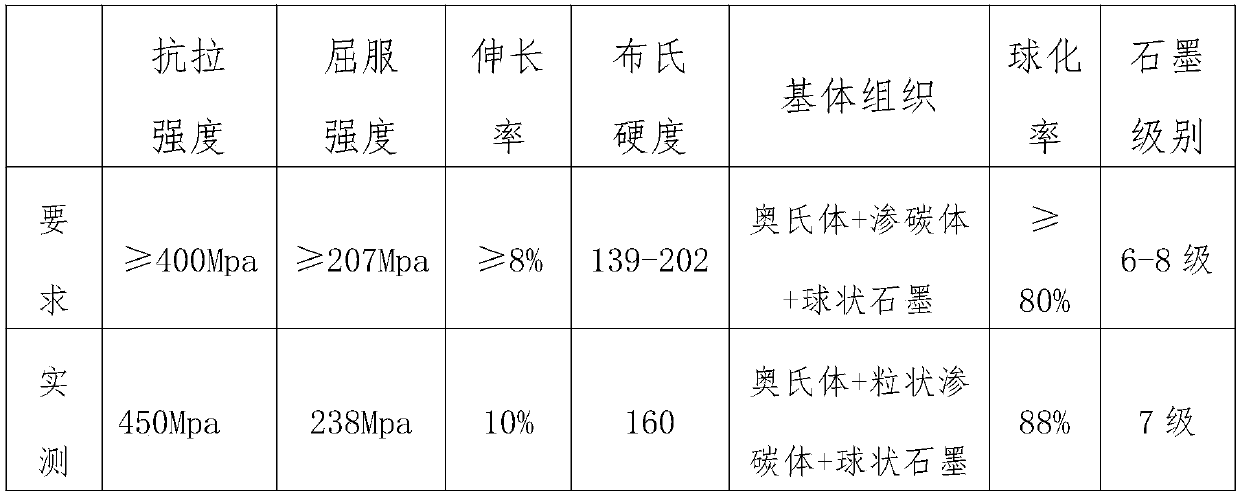

Embodiment 1

[0024] A high-nickel austenitic nodular cast iron, the austenitic nodular cast iron includes the following chemical components in weight percentage: 2.35% carbon, 1.75% silicon, 0.7% manganese, 0.05% phosphorus, 18% nickel, 1.75% chromium, magnesium 0.05%, the balance is iron.

[0025] A production process of high-nickel austenitic nodular cast iron, the production process comprises the following steps:

[0026] (1) Preparation of ingredients: prepare ingredients according to the following parts by weight ratio: 150 parts of pig iron, 320 parts of steel scrap, 11.5 parts of recarburizer, 120 parts of nickel plate, 19.5 parts of micro-carbon ferrochrome, 8.5 parts of ferromanganese, silicon Iron 10 parts;

[0027] (2) Intermediate frequency furnace smelting: first put pig iron and scrap steel into the furnace, and add carburant to the middle and lower part of the electric furnace. After the pig iron and scrap steel are melted, add nickel plate, micro-carbon ferrochromium, ferr...

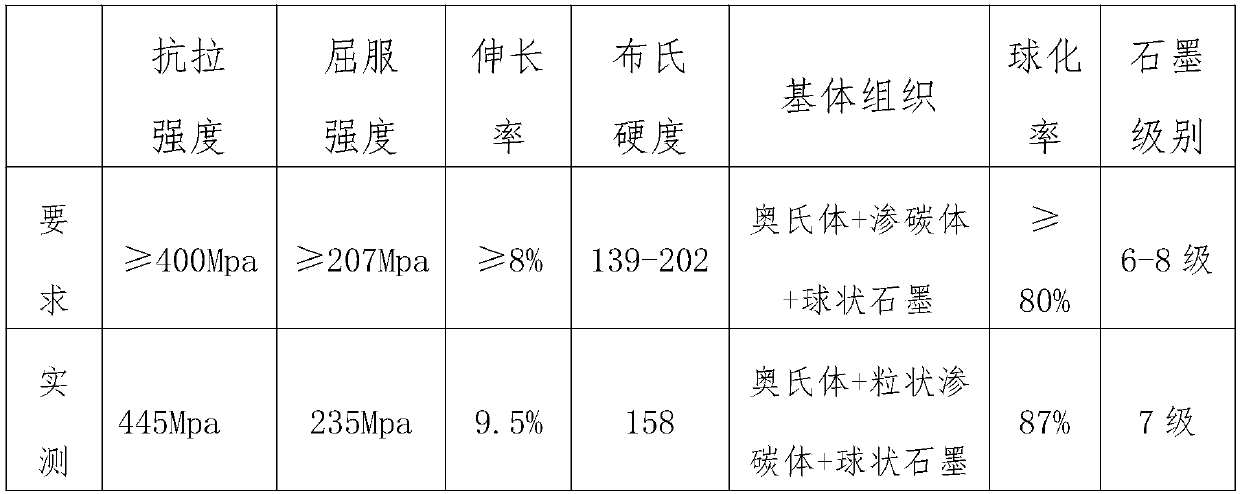

Embodiment 2

[0038] A high-nickel austenitic nodular cast iron, the austenitic nodular cast iron includes the following chemical components in weight percentage: 2.7% carbon, 2.0% silicon, 0.9% manganese, 0.04% phosphorus, 19.5% nickel, 1.9% chromium, magnesium 0.065%, the balance is iron.

[0039] A production process of high-nickel austenitic nodular cast iron, the production process comprises the following steps:

[0040] (1) Preparation of ingredients: prepare ingredients according to the following parts by weight ratio: 150 parts of pig iron, 320 parts of steel scrap, 11.5 parts of recarburizer, 120 parts of nickel plate, 19.5 parts of micro-carbon ferrochrome, 8.5 parts of ferromanganese, silicon Iron 10 parts;

[0041] (2) Intermediate frequency furnace smelting: first put pig iron and scrap steel into the furnace, and add carburant to the middle and lower part of the electric furnace. After the pig iron and scrap steel are melted, add nickel plate, micro-carbon ferrochromium, ferr...

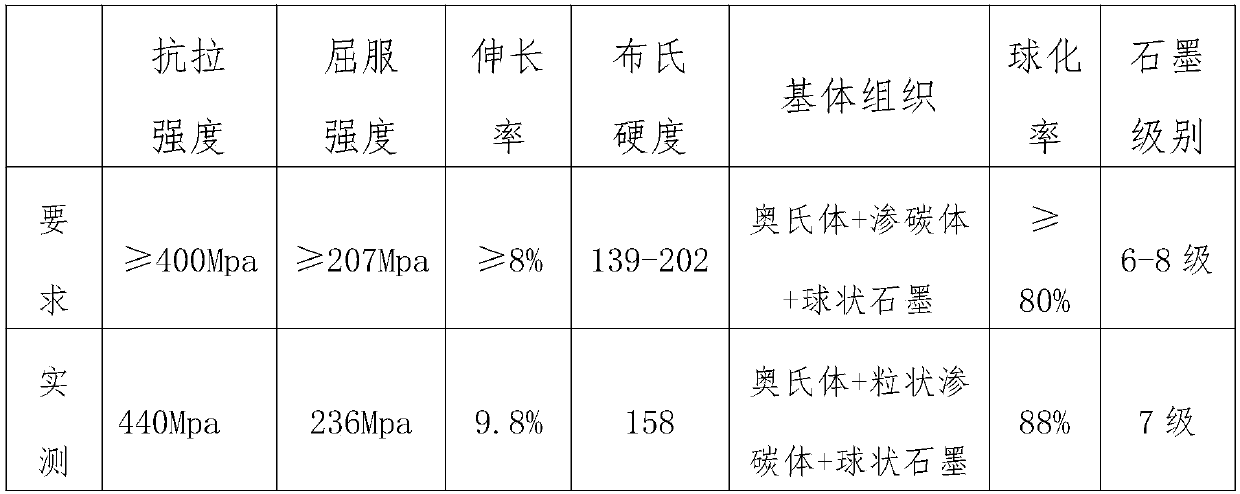

Embodiment 3

[0052] A high-nickel austenitic nodular cast iron, the austenitic nodular cast iron includes the following chemical components in weight percentage: 2.45% carbon, 1.5% silicon, 0.8% manganese, 0.03% phosphorus, 18.5% nickel, 1.85% chromium, magnesium 0.06%, the balance is iron.

[0053] A production process of high-nickel austenitic nodular cast iron, the production process comprises the following steps:

[0054] (1) Preparation of ingredients: prepare ingredients according to the following parts by weight ratio: 150 parts of pig iron, 320 parts of steel scrap, 11.5 parts of recarburizer, 120 parts of nickel plate, 19.5 parts of micro-carbon ferrochrome, 8.5 parts of ferromanganese, silicon Iron 10 parts;

[0055] (2) Intermediate frequency furnace smelting: first put pig iron and scrap steel into the furnace, and add carburant to the middle and lower part of the electric furnace. After the pig iron and scrap steel are melted, add nickel plate, micro-carbon ferrochromium, fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com