Konjac glucomannan membrane haze-prevention mask

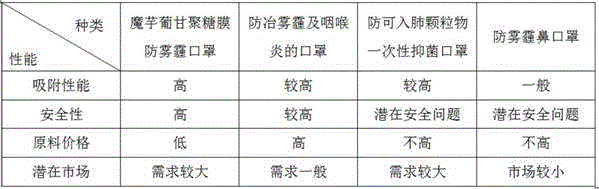

A technology of konjac glucomannan and glucomannan film, which is applied in the field of sanitary products, can solve the problems of safety, poor particle adsorption effect, and no prevention of inhalable particles, and achieves excellent material performance and large application. Potential, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of preparation method of konjac glucomannan film anti-smog mask comprises the following steps:

[0026] (1) Preparation of konjac glucomannan porous membrane: take 1g of konjac glucomannan fine powder, 99g of ultrapure water, homogeneously swell at a constant temperature, import it into a plate with the same cross-sectional size as the mask, pretreat at -18°C for 8 hours, and then- Vacuum freeze-drying at 50°C and 10Pa to make a porous konjac glucomannan film;

[0027] (2) Preparation of nanoporous konjac glucomannan membrane: Konjac glucomannan nanoporous membrane is used as the filter layer. Take 1g of konjac glucomannan fine powder and 99g of ultrapure water. The film material is then pretreated at -18°C for 8 hours, then vacuum freeze-dried at -50°C at 10Pa to make a nanoporous film of konjac glucomannan;

[0028] (3) Material selection: The konjac glucomannan film anti-fog mask has four layers, the first layer and the fourth layer, that is, th...

Embodiment 2

[0030] Embodiment 2, a kind of preparation method of konjac glucomannan film anti-smog mask comprises the following steps:

[0031] (1) Preparation of konjac glucomannan porous membrane: Take 2g of konjac glucomannan fine powder, 98g of ultrapure water, homogeneously swell at a constant temperature, import it into a plate with the same cross-sectional size as the mask, pretreat at -18°C for 8 hours, and then- Vacuum freeze-drying at 50°C and 10Pa to make a porous konjac glucomannan film;

[0032] (2) Preparation of nanoporous konjac glucomannan membrane: the nanoporous konjac glucomannan membrane is used as the filter layer. Take 2 g of konjac glucomannan fine powder and 98 g of ultrapure water. The film material is then pretreated at -18°C for 8 hours, then vacuum freeze-dried at -50°C at 10Pa to make a nanoporous film of konjac glucomannan;

[0033] (3) Material selection: The konjac glucomannan film anti-fog mask has four layers, the first layer and the fourth layer, that ...

Embodiment 3

[0035] Embodiment 3, a kind of preparation method of konjac glucomannan film anti-smog mask, comprises the following steps:

[0036](1) Preparation of konjac glucomannan porous membrane: Take 1.5g of konjac glucomannan fine powder and 98.5g of ultrapure water, and after constant temperature and homogeneous swelling, import it into a plate with the same cross-sectional size as the mask, pretreat at -18°C for 8h, Then -50 ℃, 10Pa vacuum freeze-drying, make konjac glucomannan porous film;

[0037] (2) Preparation of nanoporous konjac glucomannan membrane: the nanoporous konjac glucomannan membrane is used as the filter layer. Take 1.5g of konjac glucomannan fine powder and 98.5g of ultrapure water. After constant temperature and homogeneous swelling, use a high voltage electric field Prepare nano-membrane material, then pre-treat at -18°C for 8h, and freeze-dry at -50°C under 10Pa vacuum to make konjac glucomannan nanoporous membrane;

[0038] (3) Material selection: The konjac ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com