Washing tablet

A technology for washing tablets and washing auxiliaries, which is applied in the directions of detergent materials, detergent compositions, detergent compounding agents, etc. The effect of good effect, easy storage and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A detergent tablet formulated from the following raw materials:

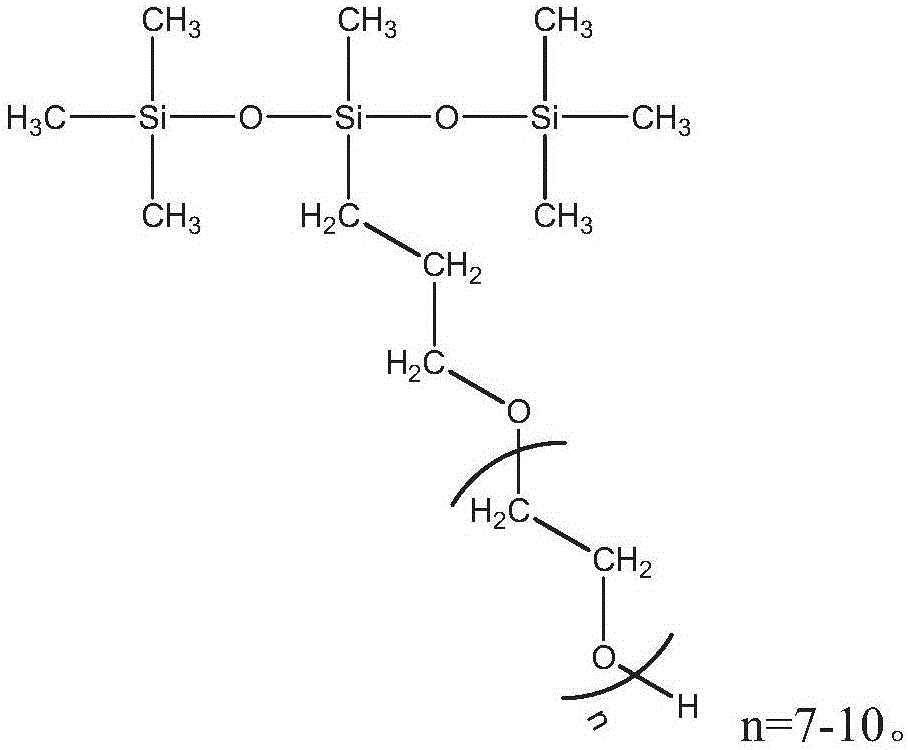

[0033] Anionic surfactant sodium lauryl sulfate 25g, nonionic surfactant coconut oil fatty acid diethanolamine 15g, amphoteric surfactant cocamidopropyl betaine 3g, disintegrant ethylenediaminetetraacetic acid 2g, sodium acetate 3g , ethoxylated polytrisiloxane (n=7-8) 5g, complexing agent sodium citrate 5g, wetting agent glycerin 4g, film-forming substance polyvinyl alcohol 17g, detergent aid zeolite 20g, jasmine essence 0.5g, blue pigment 0.1g, methylparaben 0.6g, water 50g.

[0034] A preparation method for washing tablets, comprising the following steps:

[0035] 1) 25g sodium lauryl sulfate, 15g coconut oil fatty acid diethanolamine, 3g cocamidopropyl betaine, 2g ethylenediaminetetraacetic acid, 3g sodium acetate, 5g ethoxylated polytrisiloxane ( n=7-8), 5g sodium citrate, 4g glycerin, 17g polyvinyl alcohol, 20g zeolite, 0.5g jasmine essence, 0.1g blue pigment, 0.6g methylparaben were added to 50g ...

Embodiment 2

[0038] A detergent tablet formulated from the following raw materials:

[0039] Anionic surfactant α-alkenyl sodium sulfonate 30g, nonionic surfactant fatty alcohol polyoxyethylene ether AEO-9 10g, coconut oil fatty acid diethanolamine 3g, amphoteric surfactant dodecyl dimethyl betaine 4g , disintegrant citric acid 5g, sodium bicarbonate 5g, ethoxylated polytrisiloxane (n=7-8) 6g, complexing agent sodium acetate 10g, film-forming substance polyvinylpyrrolidone 19g, wetting agent Propylene glycol 3g, lotus essence 0.5g, Kathon (isothiazolinone) 0.5g, water 55g.

[0040] A preparation method for washing tablets, comprising the following steps:

[0041] 1) Mix 30g sodium α-olefin sulfonate, 10g fatty alcohol polyoxyethylene ether AEO-9, 3g coconut oil fatty acid diethanolamine, 4g dodecyl dimethyl betaine, 5g citric acid, 5g sodium bicarbonate, 6g Add ethoxylated polytrisiloxane (n=7-8), 10g sodium acetate, 19g polyvinylpyrrolidone, 3g propylene glycol, 0.5g lotus essence, and ...

Embodiment 3

[0044] A detergent tablet formulated from the following raw materials:

[0045]Anionic surfactant sodium secondary alkyl sulfonate 20g, lauryl ammonium sulfate 5g, nonionic surfactant isotridecyl alcohol polyoxyethylene ether 12g, disintegrant sodium bicarbonate 3g, tartaric acid 4g, ethoxylate Modified polytrisiloxane (n=9-10) 5g, complexing agent sodium acetate 10g, tetrasodium edetate 2g, wetting agent polyethylene glycol 40010g, film-forming substance polyvinyl alcohol 17g, carboxylate Sodium methylcellulose 0.5g, detergent builder kaolin 5g, jasmine essence 0.5g, red pigment 0.1g, Bropol 0.4g, water 60g.

[0046] A preparation method for washing tablets, comprising the following steps:

[0047] 1) 20g secondary alkyl sodium sulfonate, 5g lauryl ammonium sulfate, 12g isomeric tridecyl alcohol polyoxyethylene ether, 3g sodium bicarbonate, 4g tartaric acid, 5g ethoxylated polytrisiloxane ( n=9-10), 10g sodium acetate, 2g tetrasodium edetate, 10g polyethylene glycol 400, 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com