A kind of high thermal conductivity diamond-metal composite material and preparation method thereof

A technology of metal composite materials and composite materials, which is applied in the field of high thermal conductivity diamond-metal composite materials and its preparation, can solve the problem that composite materials cannot be applied well, affect the thermal conductivity of the composite material matrix, and the thermal conductivity of the interface layer is low And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] The invention provides a kind of preparation method of described composite material, described method comprises the steps:

[0109] a-1) providing a homogeneous mixture A composed of diamond particles, boron raw material and organic solution;

[0110] a-2) under vacuum, heat-treat the mixture A to obtain a diamond composite;

[0111] b-1) providing a mixture B of the diamond composite body and metal raw material obtained in step a-2);

[0112] b-2) hot pressing and sintering the mixture B to obtain the composite material according to claim 1.

[0113] Specifically, based on the total weight of the mixture A, the content of diamond particles is 80-99wt%; and / or

[0114] The content of the boron raw material is 1-15wt%.

[0115] Typically, based on the total weight of the mixture A, the content of diamond particles is 85-99wt%, preferably 85-95wt%.

[0116] Typically, based on the total weight of the mixture A, the content of the boron raw material is 1-12wt%, prefera...

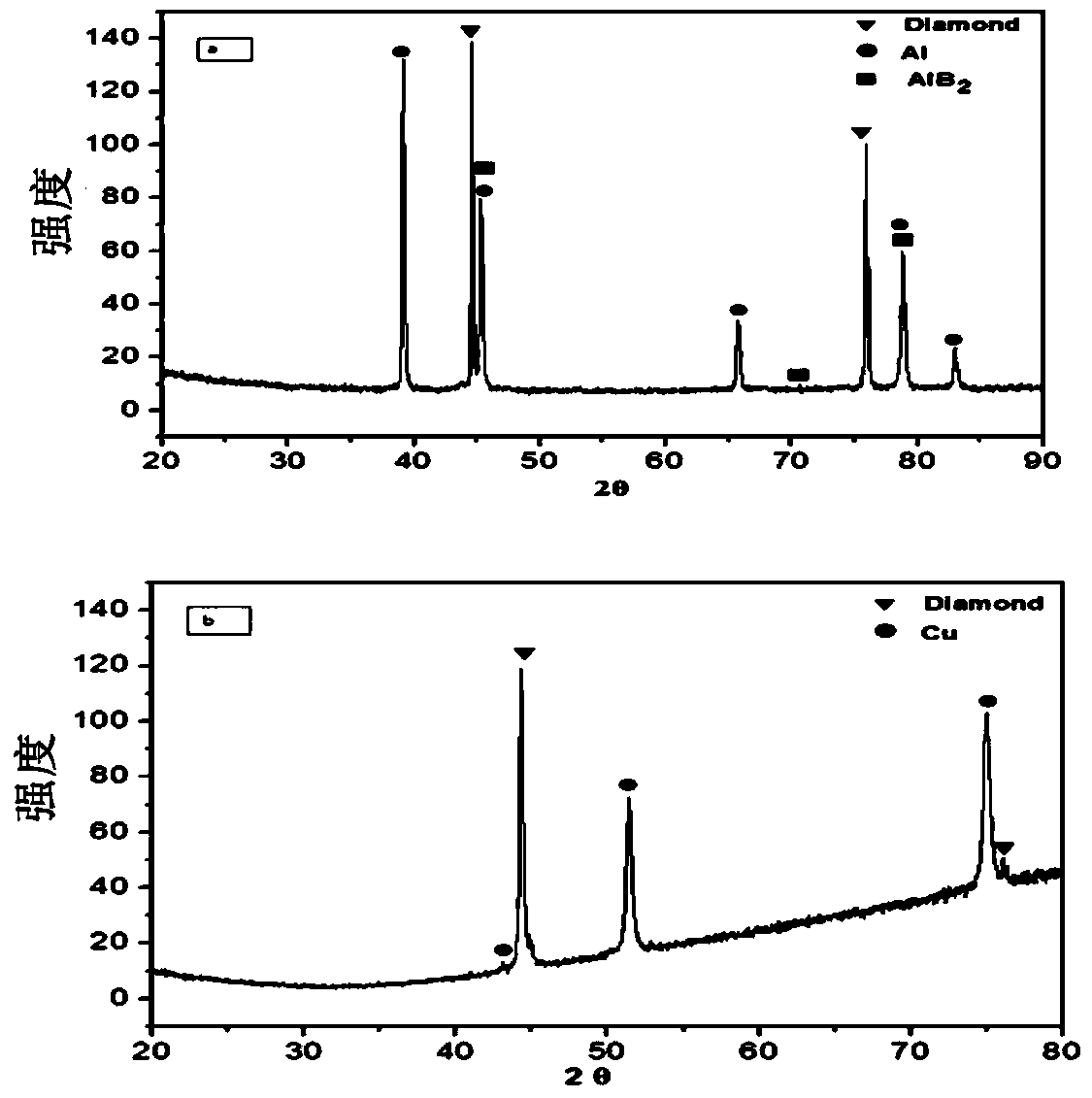

Embodiment 1

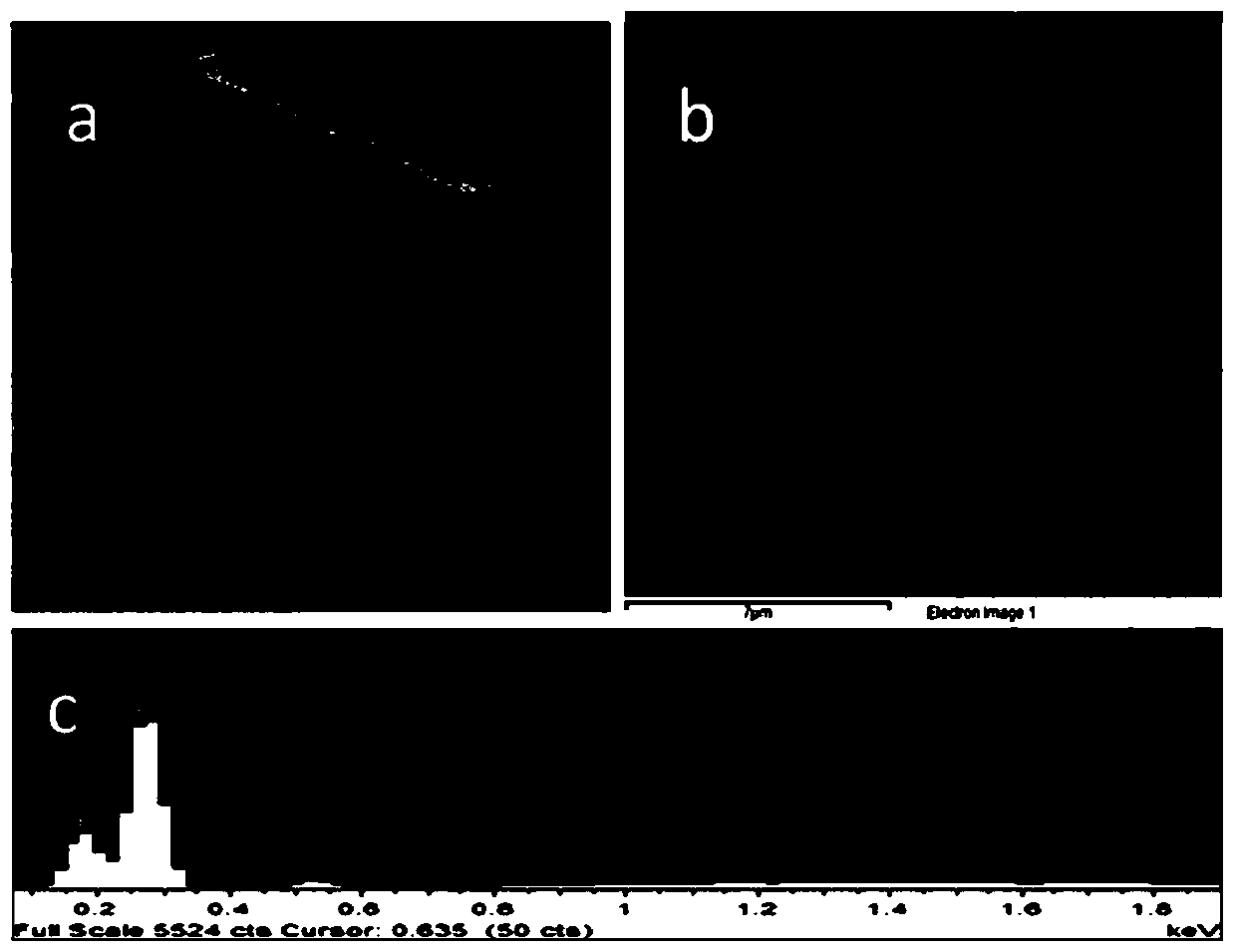

[0140] 1.1 Preparation of diamond composite 1

[0141] Diamond particles with an average particle diameter of about 200 μm, a small amount of boron powder and a 5% polyvinyl alcohol aqueous solution are uniformly mixed to form a mixture. Wherein, calculated by the total weight of the mixture, the mass fraction of the B powder is 10%, and the mass fraction of the diamond particles is 85%. Put the mixture into a vacuum carbon tube furnace, and evacuate to a vacuum degree of 10 -2 Pa, raise the temperature to 1300°C at a heating rate of 10°C / min, keep the temperature for 60min, and then cool to room temperature with the furnace. The high-temperature-treated mixture is taken out, passed through 30-mesh, 60-mesh, 80-mesh, 100-mesh, and 150-mesh sieves to remove excess boron powder, and obtain a diamond composite 1 with a boride layer grown on the surface.

[0142] result

[0143] The surface morphology and composition of the diamond composite 1 were tested.

[0144] figure 1 I...

Embodiment 2

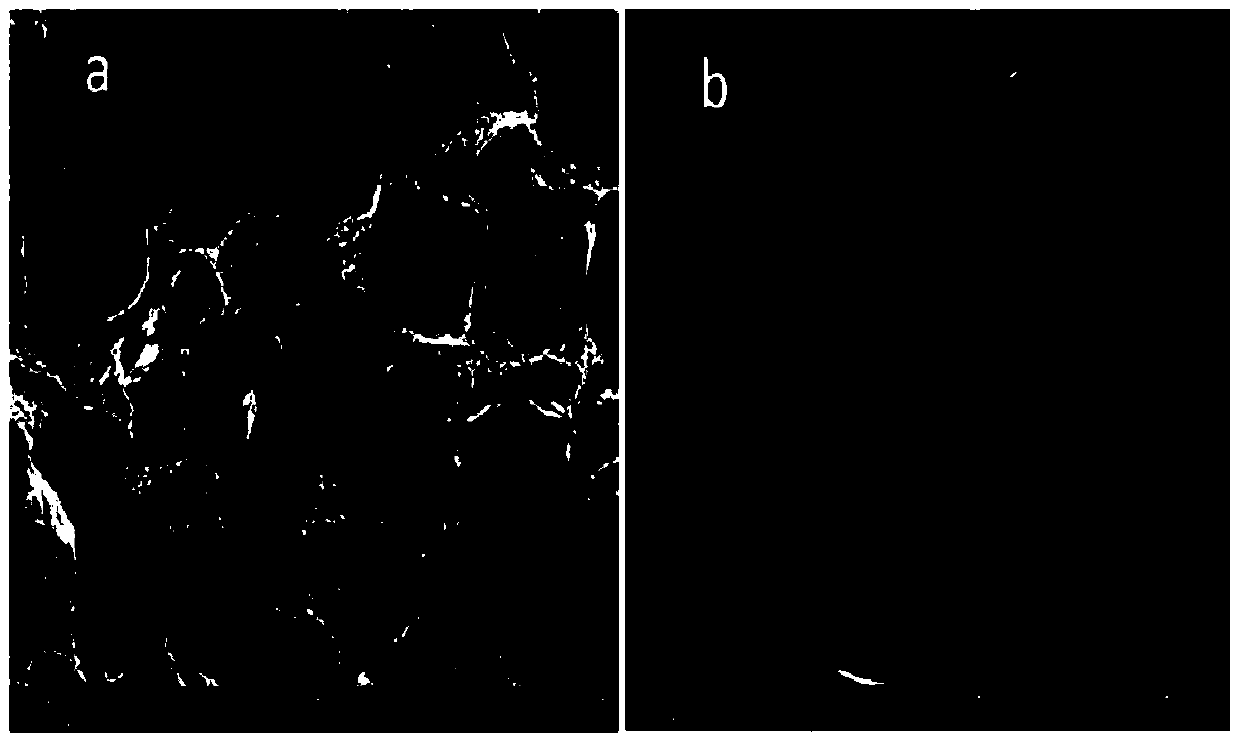

[0152] 2.1 Preparation of diamond composite 2

[0153] Diamond particles with an average particle diameter of about 300 μm, a small amount of boron powder and a polyethylene glycol aqueous solution with a concentration of 5% are uniformly mixed to form a mixture. Wherein, according to the total weight of the mixture, the mass fraction of B powder is 10%, and the mass fraction of diamond is 80%. Put the above mixture into a vacuum carbon tube furnace, and evacuate to a vacuum degree of 10 -2 Pa, raise the temperature to 1250°C at a heating rate of 10°C / min, keep the temperature for 60min, and then cool to room temperature with the furnace. Take out the high-temperature-treated mixture, pass through sieves of 30 mesh, 60 mesh, 80 mesh, 100 mesh, and 150 mesh respectively to remove excess boron powder, and obtain a diamond composite 2 with a boride layer grown on the surface.

[0154] 2.2 Preparation of diamond-aluminum composite material 2

[0155] Put the diamond composite 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com