Composite diaphragm used for lithium-sulfur battery, preparation method and application thereof

A lithium-sulfur battery and composite separator technology, which is applied in the field of energy materials, can solve the problems of low Coulomb efficiency, poor electronic and ionic conductivity, and hinder the commercialization of lithium-sulfur batteries, and achieves simple and controllable processes, low cost, and benefits The effect of large-scale implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

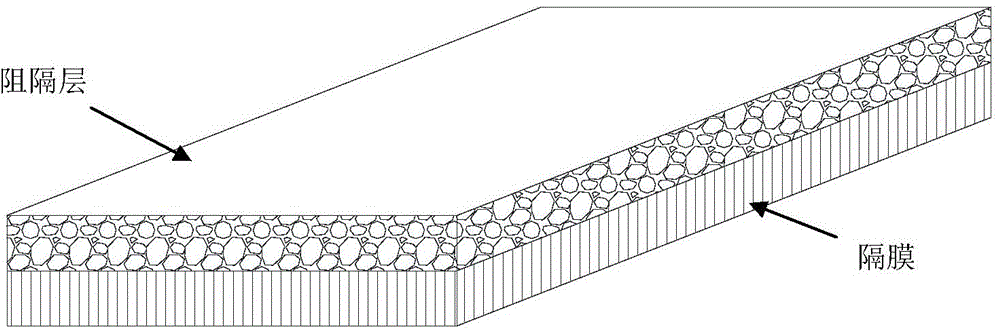

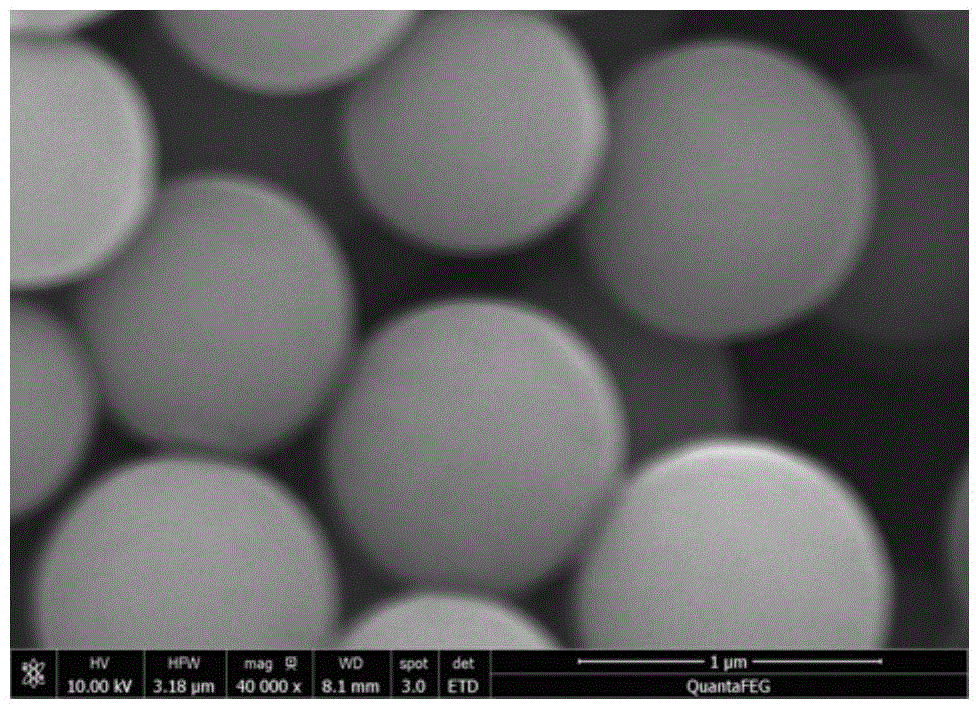

[0037] Example 1 with 1mg TiO 2 Microspheres (particle size 900nm-1.1μm, specific surface area 17.3m 3 / g) Ultrasonic dispersion in water, then suction filtration on a commercial glass fiber membrane (Whatman, GF / A), vacuum drying for 24 hours, and then the composite membrane (barrier layer thickness about 10 μm) was assembled as a separator for a lithium-sulfur battery The 2032 button cell was tested for battery performance and compared with a 2032 button cell constructed with the same glass fiber separator at the same current density (1A / g). And, under the same current density (1A / g) in the non-sulfurized electrode, the contribution of the solid inorganic compound on the composite separator to the capacity was tested. The discharge specific capacity is only 84.7mAh / g after 100 cycles at a current density of 1A / g without a composite separator at a current density of 0.1A / g; while the spherical titanium dioxide / glass fiber composite separator is used at 0.1A The first dischar...

Embodiment 2

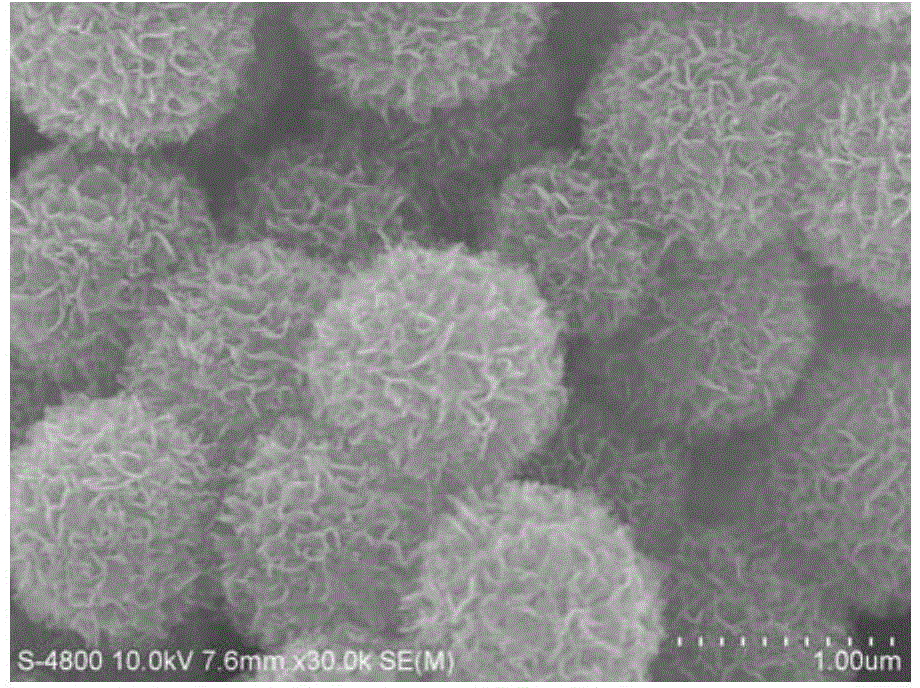

[0038] Embodiment 2 will 1mg flower-like TiO 2 Microspheres (particle size 900nm-1.1μm, specific surface area 99.2m 3 / g), and then suction-filtered (Whatman, GF / A) on a commercial glass fiber separator, vacuum-dried for 24 hours, and then assembled the composite film (barrier layer thickness about 10 μm) into a 2032-type button battery as a separator of a lithium-sulfur battery The battery performance test was carried out and compared with the battery performance of a 2032 button cell constructed with the same glass fiber separator at the same current density (1A / g). And, under the same current density (1A / g) in the non-sulfurized electrode, the contribution of the solid inorganic compound on the composite separator to the capacity was tested. The flower-shaped titanium dioxide / glass fiber composite separator is used for the first discharge of 1438.1mAh / g at a current density of 0.1A / g, and the discharge specific capacity is 281.9mAh / g after 100 cycles at a current density o...

Embodiment 4

[0040] Example 4 with 1.5mg Ti 3 C 2 Nanosheets (particle size 1 μm-1.5 μm) were ultrasonically dispersed in water and then suction-filtered on a commercial glass fiber separator, vacuum-dried for 24 hours, and then the composite film (barrier layer thickness about 20 μm) was assembled as a separator of a lithium-sulfur battery into a 2032 Type button battery is carried out battery performance test, and with the 10 μ m thick Ti in embodiment 3 3 C 2 / Glass fiber composite separator to compare the battery performance of the 2032 button at the same current density (1A / g). 10μm thick Ti 3 C 2 / Glass fiber composite separator is 1555.7mAh / g at the first discharge at a current density of 0.1A / g, and the discharge specific capacity is 580.2mAh / g after 60 cycles at a current density of 1A / g, 20μm thick Ti 3 C 2 / Glass fiber composite separator at a current density of 0.1A / g is 1570.1mAh / g for the first time, and after 60 cycles at a current density of 1A / g, the discharge specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com