Grinding wheel special for photovoltaic glass and production technique of grinding wheel

A photovoltaic glass and production process technology, applied in abrasives, grinding devices, manufacturing tools, etc., can solve the problems of weak adhesion between the diamond layer and the grinding wheel substrate, prone to debris, poor cutting ability, etc., to enhance wear resistance. , to avoid disintegration and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

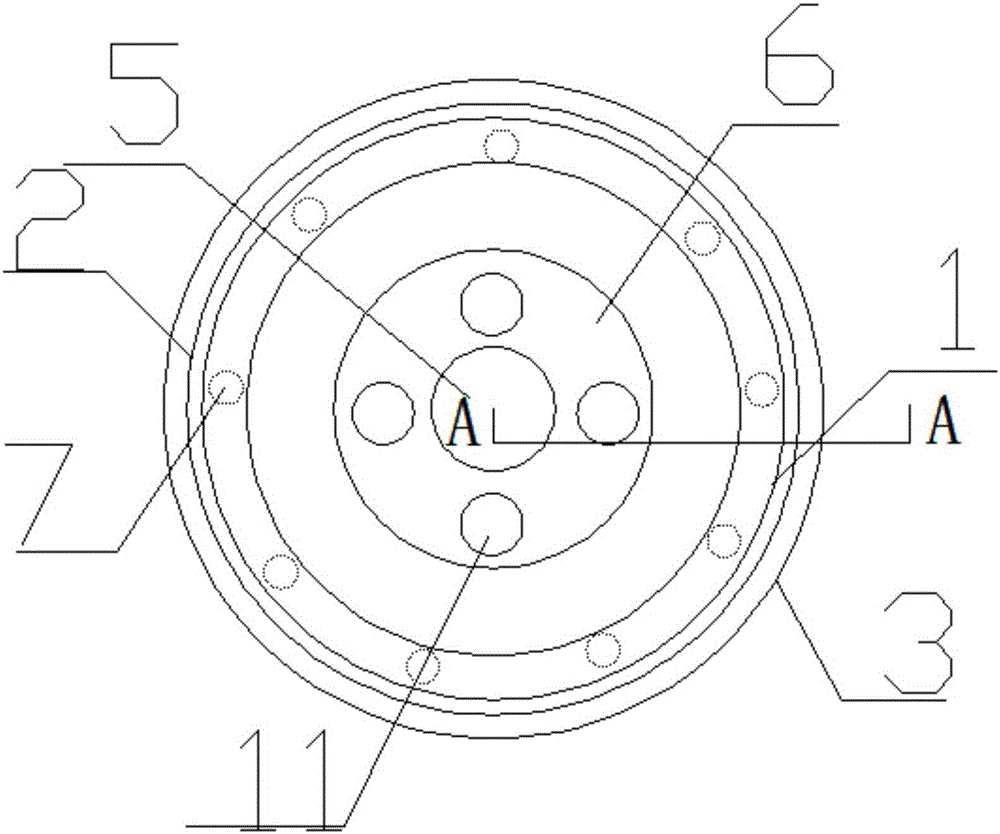

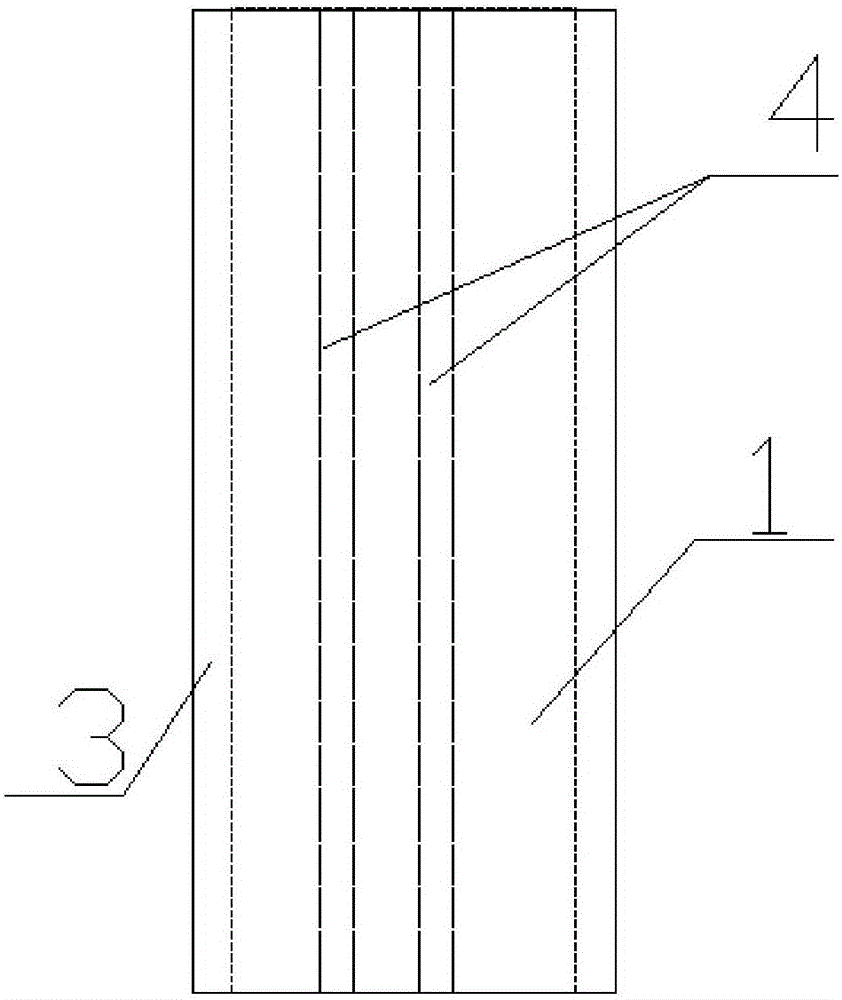

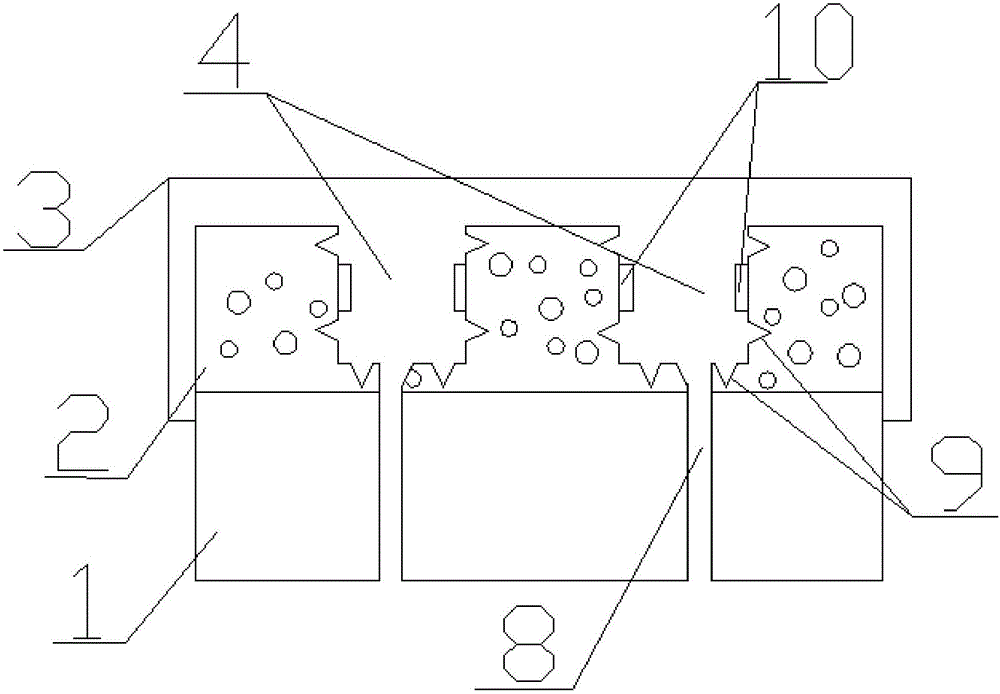

[0046] A special grinding wheel for photovoltaic glass provided in this embodiment has a structure such as Figure 1-3 As shown, it includes a grinding wheel base 1, a grinding layer 2 and a protective cover 3. The grinding wheel base 1 is made of A3 steel, the grinding layer 2 is arranged on the outer circumference of the grinding wheel base 1, and the protective cover 3 is arranged on the outer circumference of the grinding wheel base 1. Cover the grinding layer 2, the outer circumference of the grinding layer 2 is provided with at least two grooves 4, the center of the grinding wheel base 1 is provided with a mounting hole 5, and the grinding wheel base 1 is also provided with a mounting block protruding from the surface of the grinding wheel base 1 6. The mounting block 6 is located on the outer circumference of the mounting hole 5, and the mounting block 6 is evenly distributed with threaded holes 11, wherein:

[0047] A plurality of fixing holes 7 are evenly distributed ...

Embodiment 2

[0051] This embodiment provides the production process of the special grinding wheel for photovoltaic glass in the above light embodiment, and the production process specifically includes the following steps:

[0052] (1) Configure the mixture

[0053] Add nickel powder, copper powder, iron powder, cobalt powder, manganese powder and tin powder into the rocking mixer, dry mix for 20 minutes, and the stirring speed is 35r / min, wherein the components of each raw material are as follows in terms of parts by mass:

[0054] Nickel powder: 6 parts; Copper powder: 20 parts; Iron powder: 5 parts; Cobalt powder: 5 parts; Manganese powder: 5 parts; Tin powder: 2 parts;

[0055] (2) Mixed abrasive

[0056] Pour the powder mixed in the above step (1) into a basin and flatten it, use a steel spoon to press a pit in the middle of the powder, pour the diamond into it, pour the wetting agent liquid paraffin on the diamond, so that the diamond is completely wet Wet, then stir repeatedly with...

Embodiment 3

[0066] This embodiment provides the production process of the special grinding wheel for photovoltaic glass in the above light embodiment, and the production process specifically includes the following steps:

[0067] (1) Configure the mixture

[0068] Add nickel powder, copper powder, iron powder, cobalt powder, manganese powder and tin powder into the rocking mixer, dry mix for 30 minutes, and the stirring speed is 47r / min, wherein the components of each raw material are as follows in terms of parts by mass:

[0069] Nickel powder: 25 parts; Copper powder: 65 parts; Iron powder: 25 parts; Cobalt powder: 25 parts; Manganese powder: 25 parts; Tin powder: 2-15 parts;

[0070] (2) Mixed abrasive

[0071] Pour the powder mixed in the above step (1) into a basin and flatten it, use a steel spoon to press a pit in the middle of the powder, pour the diamond into it, pour the wetting agent liquid paraffin on the diamond, so that the diamond is completely wet Wet, then stir repeated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com