A kind of quaternary ammonium salt type gemini surfactant and its preparation, product and application

A technology of surfactant and quaternary ammonium salt, applied in the field of quaternary ammonium salt type Gemini surfactant and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0072] Synthetic intermediate bridge chain

[0073] (1) Synthesis of 1,2-bis(2-chloroacetamide)ethane

[0074] First, dissolve 20g of chloroacetyl chloride in 240mL of chloroform, 55.2g of potassium carbonate in 240mL of water, and 4.8g of ethylenediamine in 200mL of chloroform; then add the ethylenediamine solution into the three-necked flask, and adjust the temperature of the water bath to 0°C , and then slowly drop the chloroacetyl chloride solution and the potassium carbonate solution into the ethylenediamine solution at the same time, and the dropping time is about 1 hour. After the dropwise addition, react at room temperature for 4 h. Suction filtration and washing with water twice, and recrystallization with absolute ethanol to obtain 1,2-bis(2-chloroacetamide)ethane with a yield of 50%.

[0075]

[0076] (2) 2,4-bis(bromoacetamide)aminopyrimidine

[0077] First, dissolve 20g of chloroacetyl chloride in 240mL of chloroform, dissolve 55.2g of potassium carbonate in...

Embodiment 1

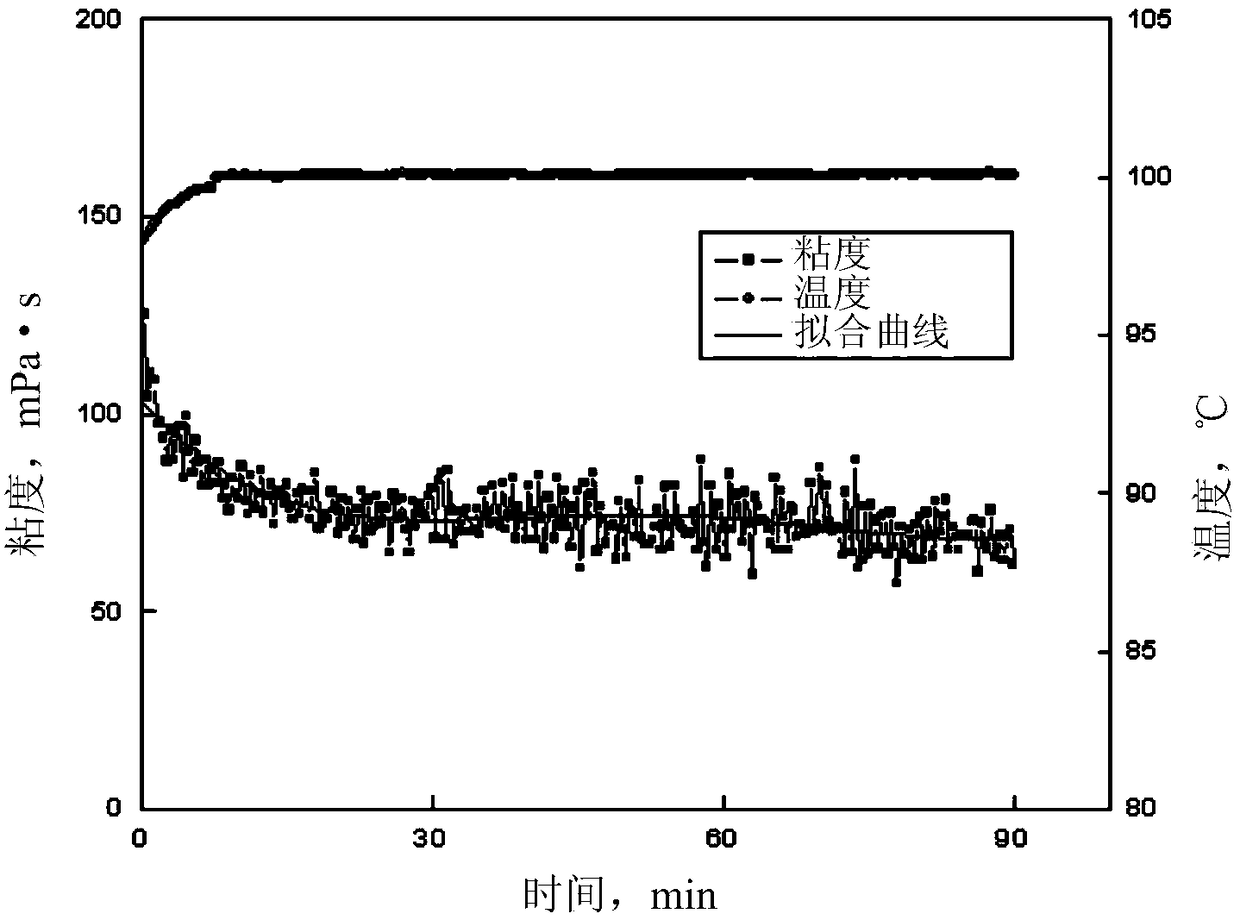

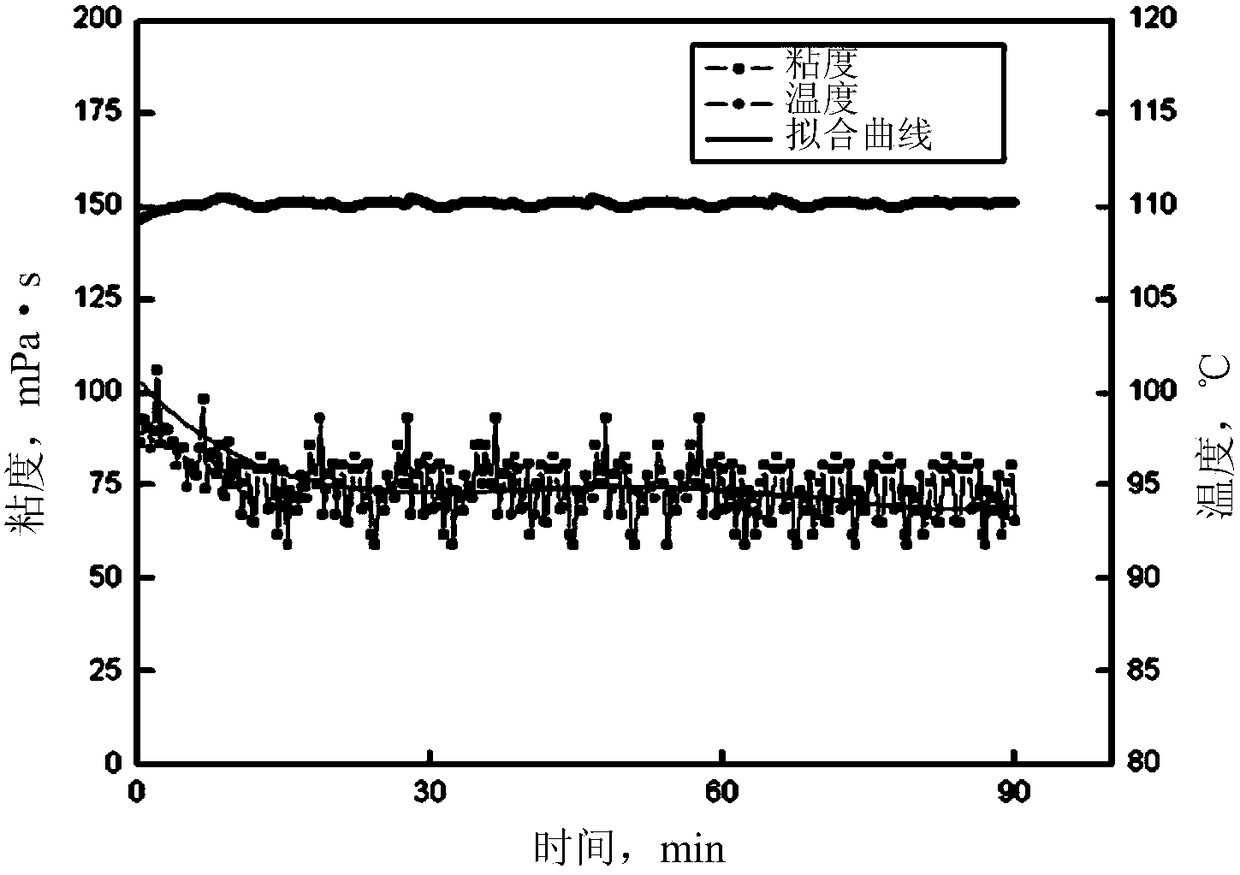

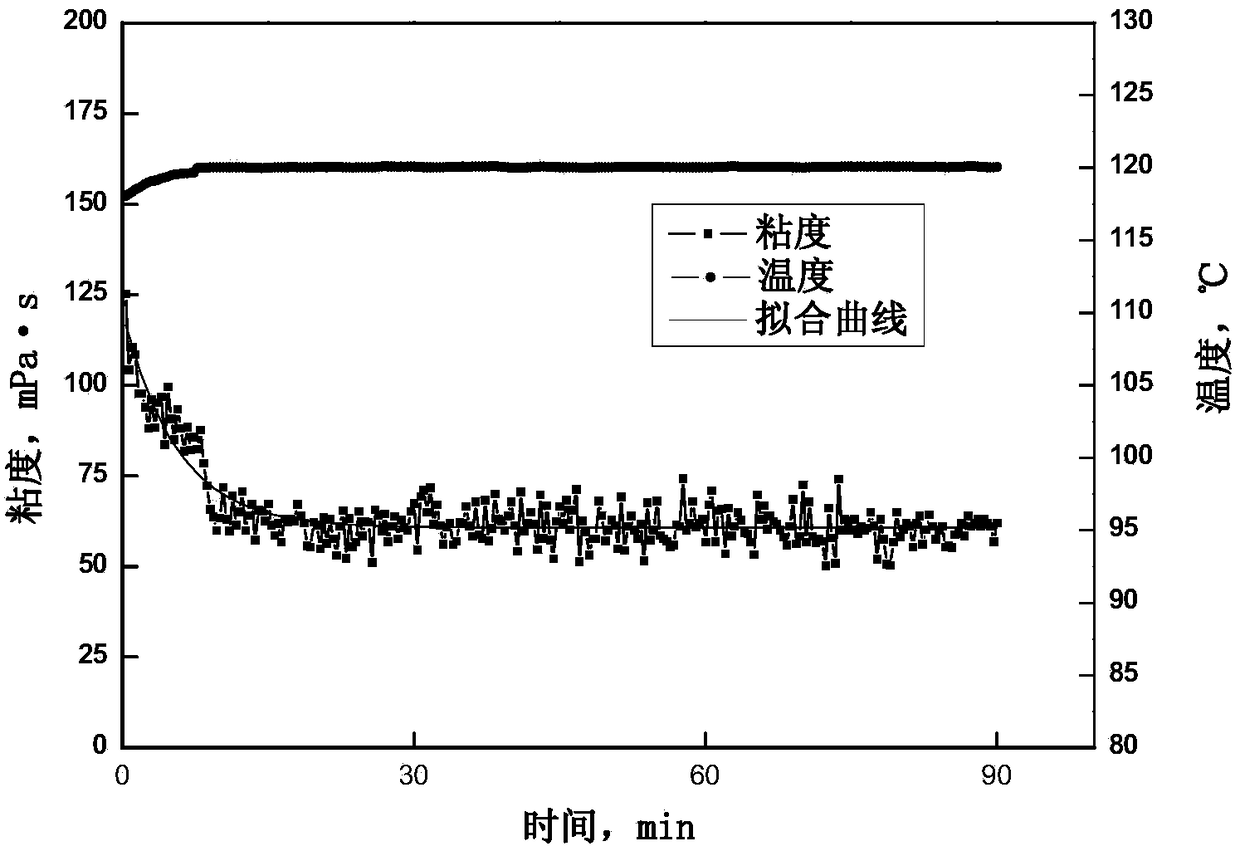

[0127] First Gemini cationic surfactant diacetyl ethylenediamine base bis[dimethylhexadecyl ammonium chloride] (preparation example synthetic Gemini surfactant (1) preparation) and water are mixed to obtain uniform transparent liquid, Then add counter ion salt ammonium chloride in transparent liquid under stirring condition, chelating agent EDTA, the mass percentage that mixes to obtain said Gemini cationic surfactant is 1.8%, and counter ion mass percentage is 1.5%, chelating agent quality The percentage is 0.2%. The medium-high temperature clean fracturing fluid obtained in this example, at 25°C for 170s -1 The viscosity under shearing is 100mPa·s, at 100°C, 110°C, 120°C, shearing for 90min, the viscosities are 80mPa·s, 75mPa·s, 60mPa·s respectively, and has good temperature and shear resistance. For the temperature and shear resistance trend graphs at 100°C, 110°C, and 120°C, please refer to the attached figure 1 , with figure 2 , with image 3 . At 95°C, a fracturing...

Embodiment 2

[0129] First Gemini cationic surfactant diacetyl ethylenediamine base bis[dimethylstearamidopropyl ammonium chloride] (preparation example synthetic Gemini surfactant (2) preparation) and water are mixed to obtain uniform transparent liquid , then add counterion salt potassium chloride, chelating agent sodium polyphosphate under stirring condition in the transparent liquid, the mass percentage that mixes to obtain said Gemini cationic surfactant is 2%, and counter ion mass percentage is 2% , the chelating agent mass percentage is 0.25%. The warm and clean fracturing fluid obtained in this example, at 25°C for 170s -1 The viscosity under shearing is 100mPa·s, at 100°C, 120°C, 140°C, shearing for 90min, the viscosities are 85mPa·s, 75mPa·s, 65mPa·s respectively, with good temperature resistance, shear resistance and portability sand properties. At 95°C, a fracturing fluid with a proppant of 20-40 mesh and a sand-to-sand ratio of 30% is selected, and its sedimentation rate is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com