Modified hydrogel material used for 3D printing and application of same to drug loading

A technology of 3D printing and gel materials, applied in the field of modified hydrogel materials and their application in drug loading, can solve the shortage of 3D printing materials, achieve good biocompatibility, expand the scope of use, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

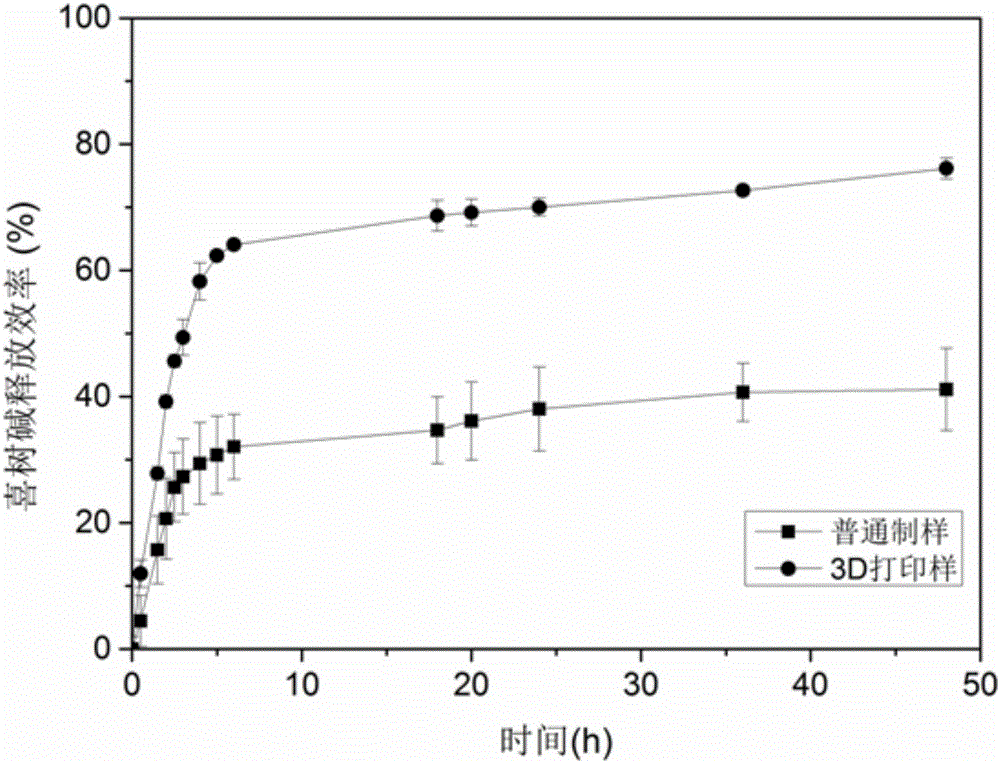

[0042] Example 1: Preparation of 3D printed drug-loaded hydrogel material

[0043] (1) Preparation of modified hydrogel material: 12.6g of Pluronic F-127 was dissolved in 100mL of a mixed solution with a volume ratio of dichloromethane: acetone = 1:1, and 3mL of acryloyl chloride and 3mL of Tris were added dropwise in an ice bath. Ethylamine, react in ice bath for 12h, and react at room temperature for 12h. After the reaction, washed with saturated sodium bicarbonate solution, rotary evaporated and vacuum dried at 40° C. for 24 hours to obtain modified F-127 (12 g).

[0044] (2) Preparation of drug-loaded hydrogel material for 3D printing: Dissolve 11 g of modified F-127 in 100 mL of pure water, add 1 g of camptothecin, stir at room temperature for 24 hours, then add 0.5 g of 2,2-di Methoxy-2-phenylethanone was mixed uniformly to obtain a printing liquid.

[0045] (3) 3D printing: Use CAD to design a cube with a size of 20*20*2mm (length, width and height) and load it into t...

Embodiment 2

[0046] Example 2: Preparation of 3D printed drug-loaded hydrogel materials

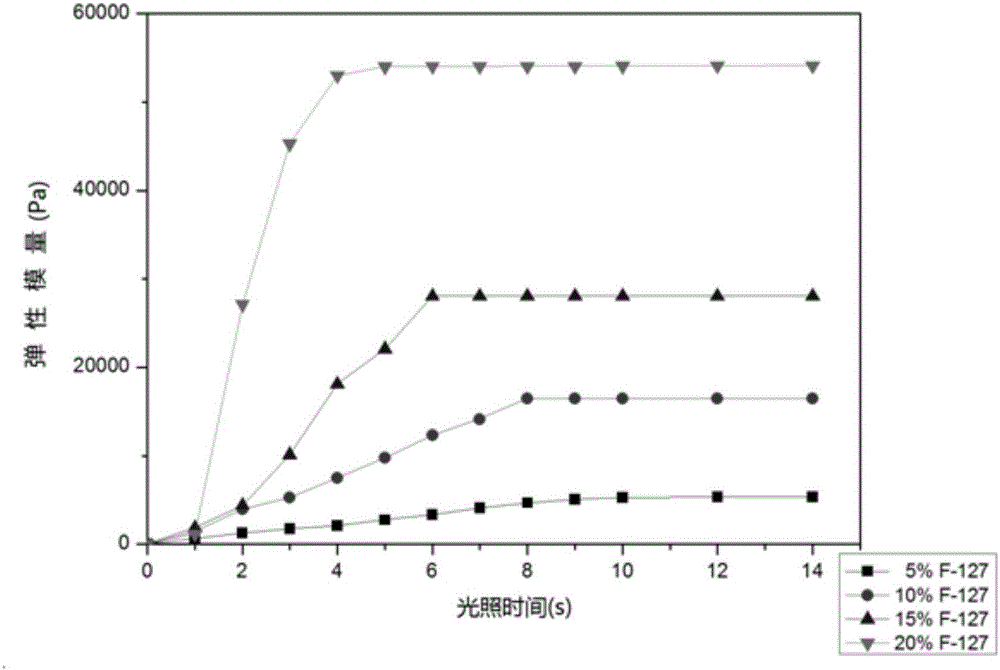

[0047] In Example 1, "dissolve 12 g of modified F-127 in 100 mL of water" is changed to "dissolve 5.3 g of modified F-127 in 100 mL of water", and the rest are the same as in Example 1. At this time, the mass fraction of modified F-127 in the printed hydrogel material is 5%. The elastic modulus was tested under different ultraviolet light irradiation times, and the results were as follows: figure 1 shown, corresponding to figure 1 5% F-127 in.

Embodiment 3

[0048] Example 3: Preparation of 3D printed drug-loaded hydrogel material

[0049] In Example 1, "dissolve 12g of modified F-127 in 100mL of water" is changed to "dissolve 18g of modified F-127 in 100mL of water", and the rest are the same as in Example 1, and the printed The mass fraction of modified F-127 in the hydrogel material is 15%. The elastic modulus was tested under different ultraviolet light irradiation times, and the results were as follows: figure 1 shown, corresponding to figure 1 15% F-127 in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com