Method for preparing small-molecular weight collagen active peptide through enzymolysis of yak bone and skin

A small molecular weight, collagen technology, applied in the field of bioengineering, to achieve high yield, small molecular weight, and easy absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

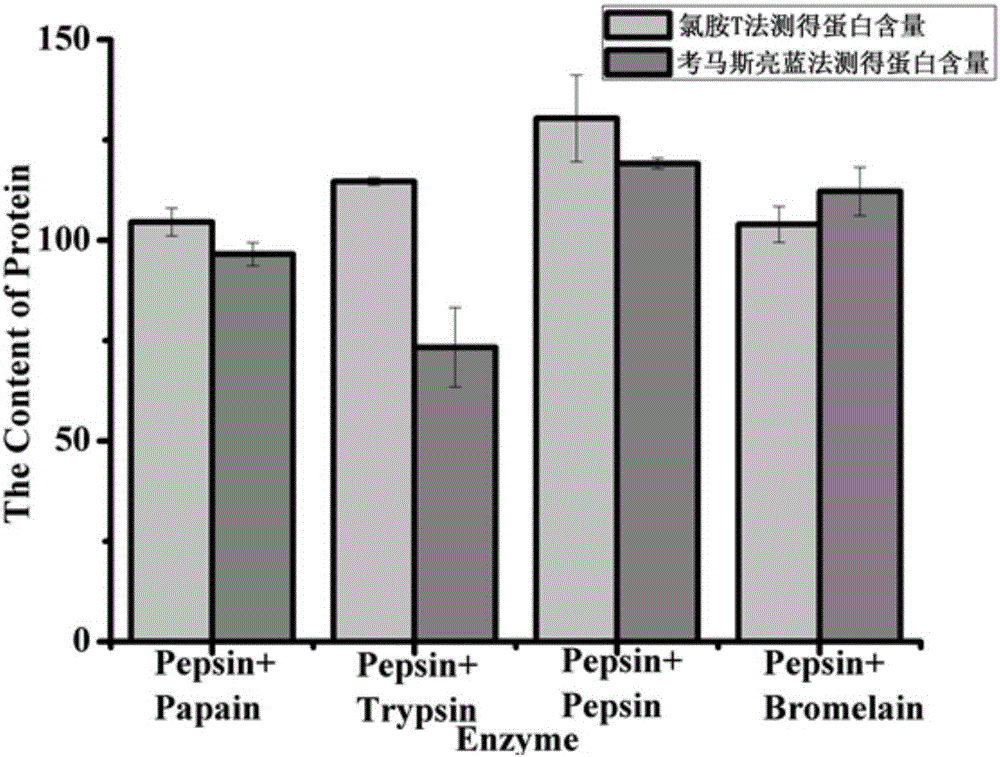

Method used

Image

Examples

Embodiment 1

[0024] Preferred embodiment 1 of the present invention provides a method for enzymatically hydrolyzing yak bone skin to prepare small molecular weight collagen active peptides. The steps are as follows:

[0025] (1) Raw material handling

[0026] The raw materials are cleaned, foreign matter is removed, dried at room temperature, and pulverized by a pulverizer to obtain a powder with a particle size of 50 mesh;

[0027] (2) The first enzyme-directed enzymatic hydrolysis

[0028] Get 1g of powder of yak bone, disperse in the solution of papain with the ratio of material to liquid weight ratio 1:3, the dosage of papain is 4000U / g, add citric acid-disodium hydrogen phosphate buffer solution to adjust pH to 5, control The pressure of the ultra-high pressure reactor is 300Mpa, and the enzymatic hydrolysis is performed for 2hrs at a temperature of 45°C;

[0029] (3) The second enzyme directional enzymatic hydrolysis

[0030] Adjust the pH of the solution after papain enzymolysis ...

Embodiment 2

[0034] The preferred embodiment 2 of the present invention provides a method for enzymatically hydrolyzing yak bone skin to prepare small molecular weight collagen active peptides. The steps are as follows:

[0035] (1) Raw material handling

[0036] The raw materials are cleaned, foreign matter is removed, dried at room temperature, and pulverized by a pulverizer to obtain a powder with a particle size of 100 mesh;

[0037] (2) The first enzyme-directed enzymatic hydrolysis

[0038] Take 10g of yak bone powder, and disperse it in the trypsin solution at a ratio of 1:5 by weight of material to liquid. The pressure of the reactor is 200Mpa, and the enzymatic hydrolysis is performed for 1.5hrs at a temperature of 45°C;

[0039] (3) The second enzyme directional enzymatic hydrolysis

[0040] Adjust the pH of the solution after trypsin enzymolysis to the optimum pH of pepsin 2.4, add pepsin, wherein the amount of pepsin is 1000U / g, control the pressure of the ultra-high pressur...

Embodiment 3

[0044] Preferred embodiment 3 of the present invention provides a method for enzymatically hydrolyzing yak bone skin to prepare small molecular weight collagen active peptides. The steps are as follows:

[0045] (1) Raw material handling

[0046] The raw materials are cleaned, foreign matter is removed, dried at room temperature, and pulverized by a pulverizer to obtain a powder with a particle size of 50 mesh;

[0047] (2) The first enzyme-directed enzymatic hydrolysis

[0048] Get the powder 10g of yak hide, with the ratio of solid-liquid weight ratio 1:3, be dispersed in the solution of papain, the consumption of papain is 4000U / g, add citric acid-disodium hydrogen phosphate buffer solution to adjust pH to 5.0, control The pressure of the ultra-high pressure reactor is 250Mpa, and the enzymatic hydrolysis is performed for 1hrs at a temperature of 45°C;

[0049] (3) The second enzyme directional enzymatic hydrolysis

[0050] Adjust the pH of the solution after papain enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com