Preparation method for polypyrrole-poly-dopamine composite coating

A technology of polydopamine and composite coatings, applied in coatings, electrolytic coatings, electrophoretic coatings, etc., can solve the problems of low utilization rate of film formation and thin films, etc., achieve improved binding force, simple preparation process, and growth promotion effect Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

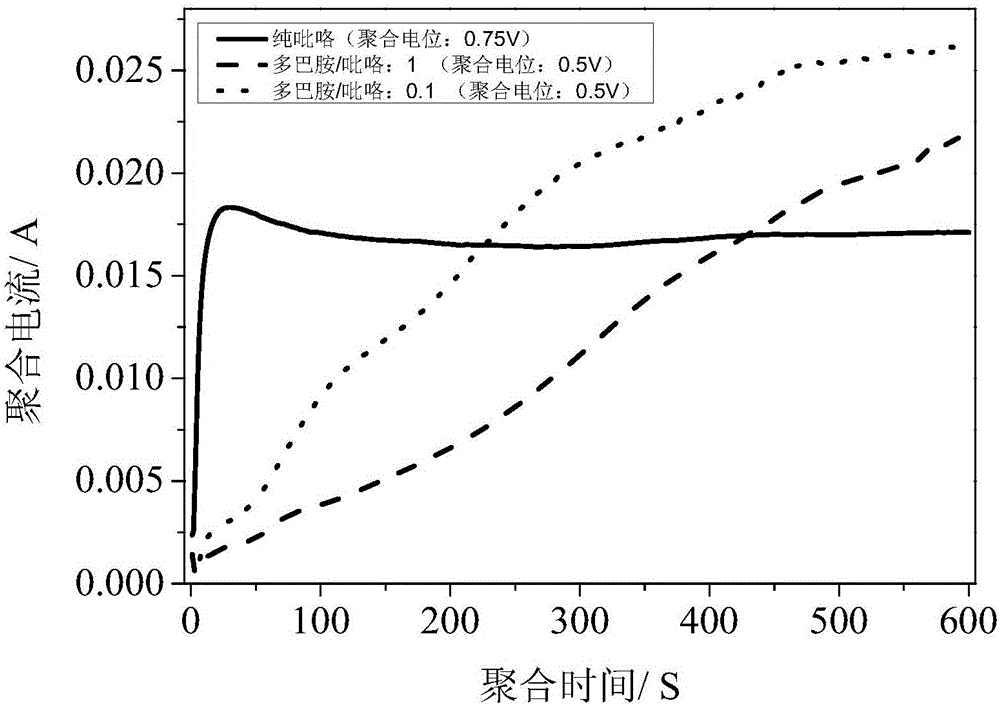

[0025] 1) Dissolve dopamine and lithium perchlorate in deionized water to form a mixed aqueous solution with the concentration of dopamine and lithium perchlorate being 0.01M and 0.1M respectively, and then dissolve the pyrrole monomer that removes impurities by secondary distillation in In the above mixed aqueous solution, dry nitrogen gas was passed through to remove dissolved oxygen therein to obtain an electrolyte solution with a final pyrrole concentration of 0.1M.

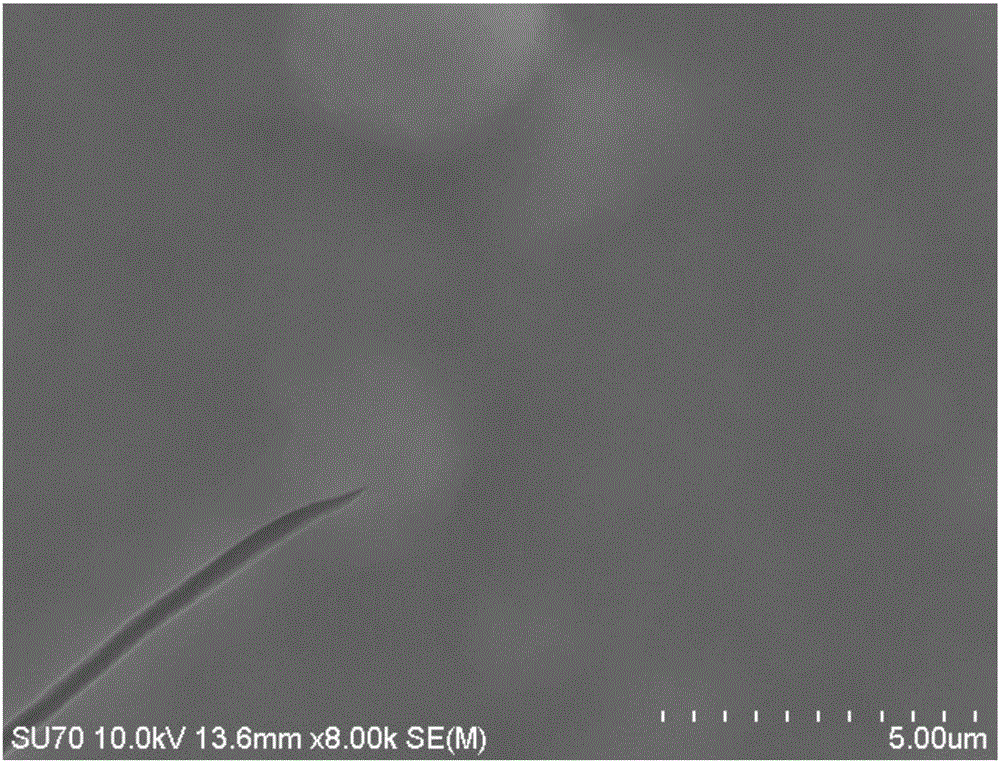

[0026] 2) A three-electrode system is used, and the area of one side is 1.5cm encapsulated by epoxy resin that has been pretreated and insulated respectively. 2 A pure titanium sheet with a thickness of 1mm was used as the working electrode, a saturated calomel electrode was used as the reference electrode, and a platinum sheet electrode was used as the counter electrode. Under the control of the electrochemical workstation, apply a working voltage of 0.5V at room temperature, and after 600 seconds, a unifo...

Embodiment 2

[0028] 1) Dissolving dopamine and lithium perchlorate in deionized water to form a mixed aqueous solution with the concentration of dopamine and lithium perchlorate being 0.2M and 0.1M respectively, and then dissolving the pyrrole monomer that removes impurities by secondary distillation in In the above mixed aqueous solution, dry nitrogen gas was passed through to remove dissolved oxygen therein to obtain an electrolyte solution with a final pyrrole concentration of 0.1M.

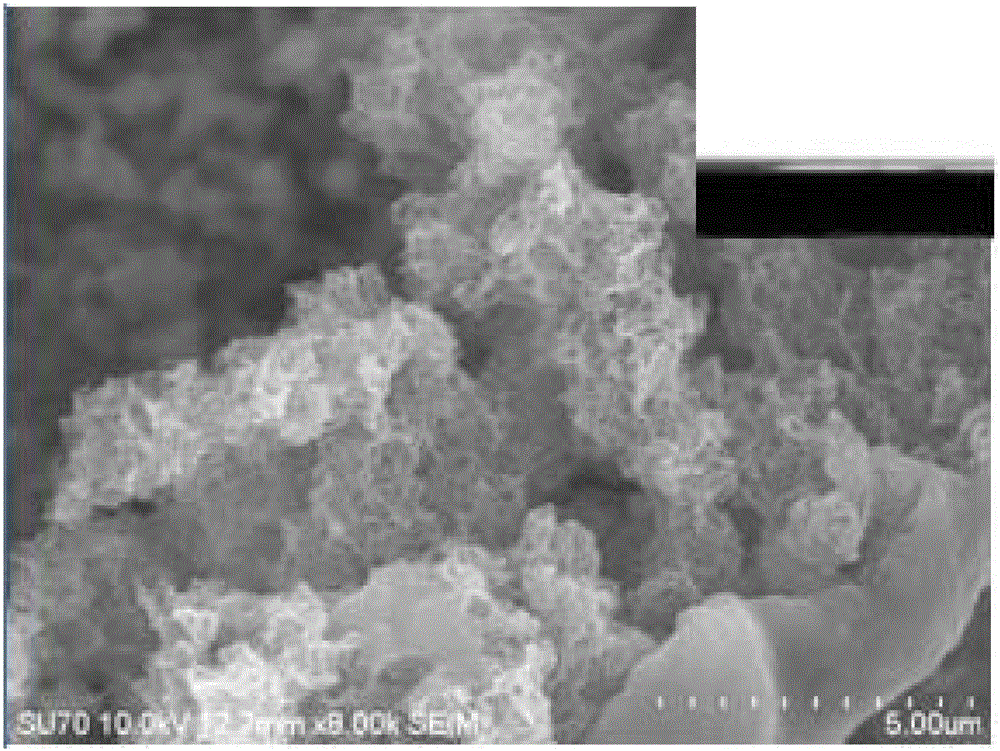

[0029] 2) A three-electrode system is used, and the area of one side is 1.5cm encapsulated by epoxy resin that has been pretreated and insulated respectively. 2 A pure titanium sheet with a thickness of 1mm was used as the working electrode, a saturated calomel electrode was used as the reference electrode, and a platinum sheet electrode was used as the counter electrode. Under the control of the electrochemical workstation, apply a working voltage of 0.5V at 20 degrees Celsius, and after 600 seconds, a ...

Embodiment 3

[0031] 1) Dissolve dopamine and sodium chloride in deionized water to form a mixed aqueous solution with the concentration of dopamine and sodium chloride being 0.008M and 0.2M respectively, and then dissolve the pyrrole monomer that removes impurities by secondary distillation in the above mixing solution In the aqueous solution, dry nitrogen gas is then introduced to remove dissolved oxygen therein to obtain an electrolyte solution with a final pyrrole concentration of 0.2M.

[0032] 2) A three-electrode system is used, and the area of one side is 2.5cm encapsulated by epoxy resin that has been pretreated and insulated respectively. 2 A pure titanium sheet with a thickness of 0.8mm was used as the working electrode, a saturated calomel electrode was used as the reference electrode, and a platinum sheet electrode was used as the counter electrode. Under the control of the electrochemical workstation, apply a working voltage of 0.45V under the condition of 30 degrees Celsius...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com