Composite drug-loading fiber for surgical sutures

A surgical suture and drug-loading technology, applied in the directions of surgery, fibrous chemical characteristics, cellulose/protein conjugated rayon, etc. release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

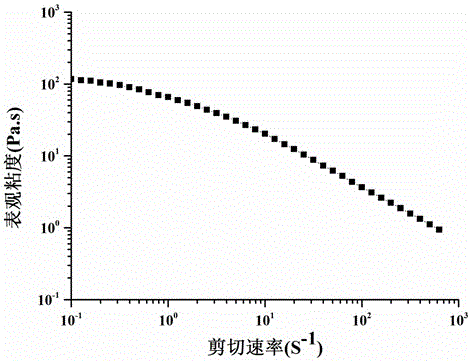

AI Technical Summary

Problems solved by technology

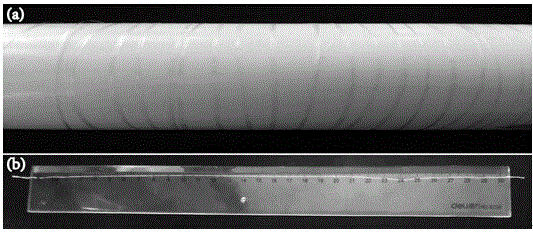

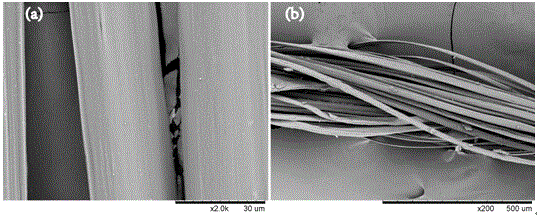

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Bacterial Cellulose A and Chitin B Solid Content A: (A+B) = 50% (w / w), Cellulose Microcrystalline C: (A+B) = 1% (w / w), Ciprosa Star D: (A+B)=1% (w / w) a composite drug-loaded fiber for surgical sutures and its preparation method:

[0032] Step (1): Solvent selection and dissolution of bacterial cellulose, chitin, cellulose microcrystals, and ciprofloxacin respectively.

[0033] Dissolve the bacterial cellulose with DMAc / LiCl mixed solvent system, place the bacterial cellulose in a freeze dryer at -50°C for 2 to 3 days, take it out and crush it, impregnate 2 g of freeze-dried bacterial cellulose in 98 g of 6 %(w / w) LiCl mixed solvent system of DMAc / LiCl, stirred and swelled at a speed of 50-100 rpm at room temperature, dissolved for 2 days until fully dissolved, and bacterial cellulose spinning with a solid content of 2% (w / w) was obtained. silk liquid;

[0034] Chitin was dissolved in DMAc / LiCl mixed solvent system, weighed 2 g chitin and placed in 98 g ...

Embodiment 2

[0041] Preparation of Bacterial Cellulose A and Chitin B Solid Content A: (A+B) = 10% (w / w), Cellulose Microcrystalline C: (A+B) = 2% (w / w), Ciprosa Star D: (A+B)=2% (w / w) a composite drug-loaded fiber for surgical sutures and its preparation method:

[0042] Step (1): Solvent selection and dissolution of bacterial cellulose, chitin, cellulose microcrystals, and ciprofloxacin respectively.

[0043] Weigh 3 g of freeze-dried bacterial cellulose and impregnate it in 97 g of DMAc / LiCl mixed solvent system containing 7% (w / w) LiCl, stir and swell at room temperature at a speed of 50-100 rpm, and dissolve for 2 days until fully dissolved. A bacterial cellulose spinning solution with a solid content of 3% was obtained; 3 g of chitin was weighed and placed in 97 g of DMAc / LiCl solvent containing 7% (w / w) LiCl, and the solid content was obtained according to the treatment method in Example 1. The content is 3% chitin spinning solution; the preparation of 10% cellulose microcrystallin...

Embodiment 3

[0047] Preparation of bacterial cellulose A and chitin B solid content A: (A+B) = 30% (w / w), cellulose microcrystalline C: (A+B) = 1% (w / w), ciprosa Star D: (A+B)=1% (w / w) a composite drug-loaded fiber for surgical sutures and its preparation method:

[0048] Step (1): Solvent selection and dissolution of bacterial cellulose, chitin, cellulose microcrystals, and ciprofloxacin respectively.

[0049] Weigh 2.5 g of freeze-dried bacterial cellulose and impregnate it in 97.5 g of DMAc / LiCl mixed solvent system containing 8% (w / w) LiCl, stir and swell at room temperature at a speed of 50-100 rpm, and dissolve for 2 days until fully dissolved. Obtain a bacterial cellulose spinning solution with a solid content of 2.5% (w / w); weigh 2.5 g of chitin and place it in 97.5 g of DMAc / LiCl solvent containing 8% (w / w) LiCl, according to Example 1 The treatment method was to obtain a chitin spinning solution with a solid content of 2.5%; the preparation of the 10% cellulose microcrystalline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com