Intracellular pH-response polylactic-acid nanometer microspheres and preparing method thereof

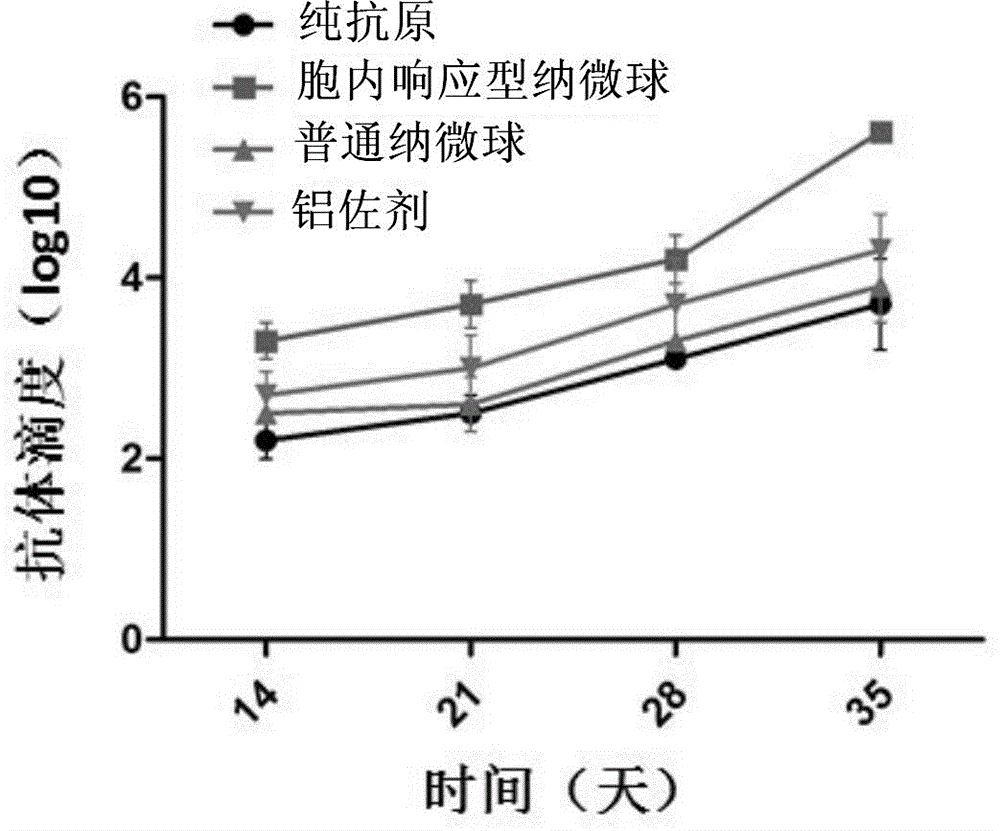

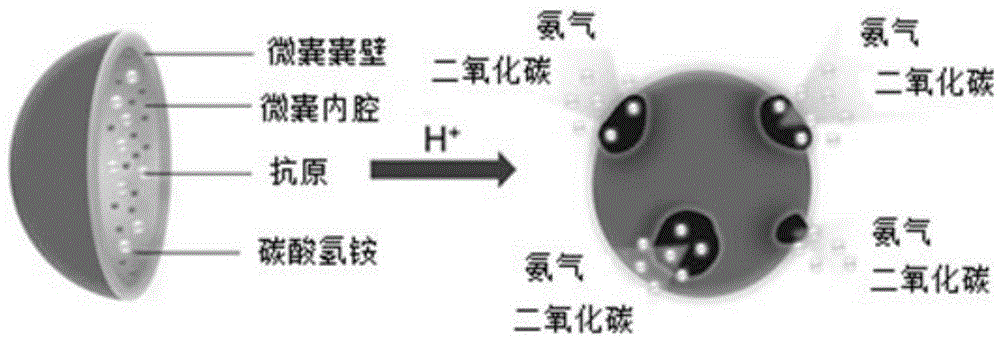

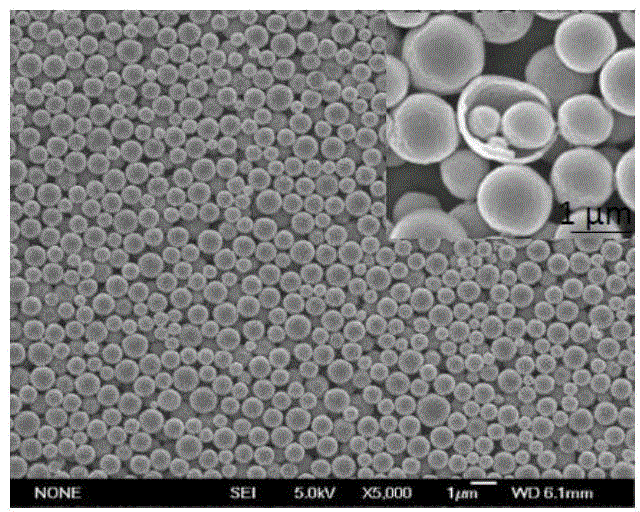

A technology of polylactic acid and nano-micro, which is applied in the field of pharmaceutical preparations in medical engineering, can solve the problems of insufficient immune response, inhomogeneity, slow release of vaccine adjuvant antigen, etc., and achieve the effect of simple preparation process and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Prepare 1.9% aqueous phase polyvinyl alcohol (PVA) as the outer water phase (W2), prepare 1mg / mL sodium bicarbonate aqueous solution and add a certain amount of OVA antigen (OVA final concentration is 5mg / mL) as the inner water phase (W1 ), the polylactic acid-polyglycolic acid copolymer (PLGA) that takes 0.264g is dissolved in the organic solvent methylene chloride of 8mL, as the oil phase (O), the inner aqueous phase that 4mL dissolves is added in the 8mL oil phase, Prepare water-in-oil primary emulsion (W1 / O) by homogenization or ultrasonic emulsification, then pour it into 60mL water phase containing polyvinyl alcohol (PVA), and after simple stirring, get water-in-oil-in-water type pre-emulsion (W1 / O / W2), transfer the pre-multiplex emulsion to the storage tank of the fast membrane emulsifier, select a 1.4 μm membrane, and pass the membrane 3 times under 1.5Mpa nitrogen pressure to prepare a uniform composite emulsion (W1 / O / W2), and then placed in a fume hood to st...

Embodiment 2

[0062] Prepare 1.5% aqueous poloxamer as the external aqueous phase (W2), prepare 5 mg / mL aqueous sodium bicarbonate solution and add a certain amount of HPV antigen (HPV final concentration is 10 μg / mL) as the internal aqueous phase (W1), A certain amount of polylactic acid-polyglycolic acid copolymer (PLGA) is dissolved in ethyl acetate as the oil phase (O), and 5 mL of the dissolved internal water phase is added to 10 mL of the oil phase, and homogenized or ultrasonically emulsified to prepare a water-in-oil type First emulsion (W1 / O), and then pour it into 75mL poloxamer aqueous phase, after simple stirring to obtain water-in-oil-in-water type pre-multiplex emulsion (W1 / O / W2), transfer the pre-multiplex emulsion to the fast In the storage tank of the membrane emulsifier, a 2.8μm membrane was selected and passed through the membrane three times under a nitrogen pressure of 1.2Mpa to prepare a double emulsion (W1 / O / W2) with uniform particle size, and then placed in a fume hoo...

Embodiment 3

[0064] Prepare 1.2% aqueous phase carboxymethylcellulose as the outer water phase (W2), prepare 2.5 mg / mL aqueous sodium bicarbonate solution and add a certain amount of HBsAg antigen (HBsAg final concentration is 10 mg / mL) as the inner water phase ( W1), a certain amount of polylactic acid copolymer (PLA) is dissolved in chloroform as the oil phase (O), and 6 mL of the dissolved internal water phase is added to 12 mL of the oil phase, and homogenized or ultrasonically emulsified to prepare a water-in-oil type primary Emulsion (W1 / O), and then pour it into 90mL carboxymethylcellulose water phase, after simple stirring to obtain water-in-oil-in-water type pre-complex emulsion (W1 / O / W2), transfer the pre-complex emulsion to the fast In the storage tank of the membrane emulsifier, a 30 μm membrane was selected and passed through the membrane three times under a nitrogen pressure of 1.0Mpa to prepare a double emulsion (W1 / O / W2) with uniform particle size, and then placed in a fume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com