Microreactor applied to ethyl alcohol and water vapor reforming reaction and preparing method of microreactor

A steam reforming and micro-reactor technology, applied in chemical instruments and methods, chemical/physical/physicochemical reactors, hydrogen/synthesis gas production, etc. High product content and other problems, to achieve the effect of improving hydrogen production rate and service life, reducing selectivity, and high ethanol conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

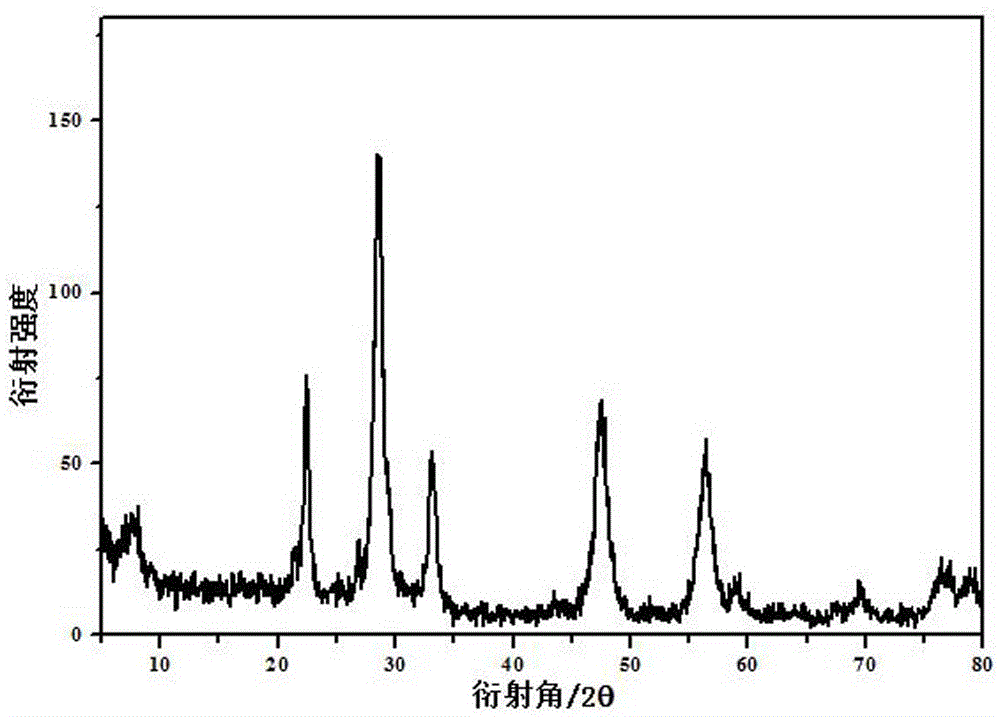

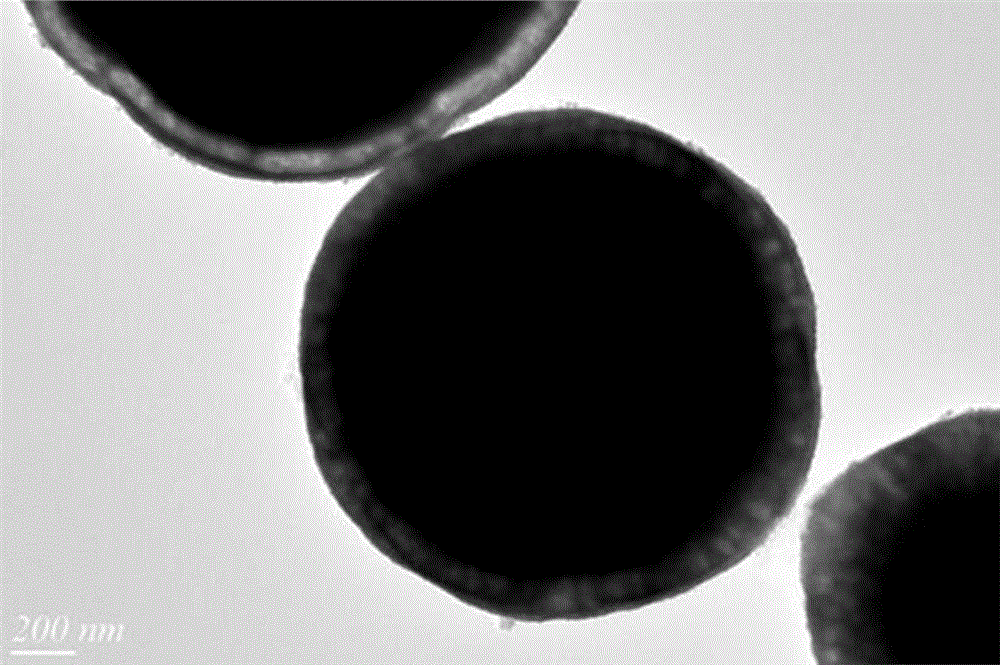

[0025] A microreactor applied to the steam reforming reaction of ethanol, including 70wt% spherical ceria and 30wt% Beta molecular sieve shell structure, the Beta molecular sieve shell structure is wrapped outside the spherical ceria, and there is a Insulate hollow structures;

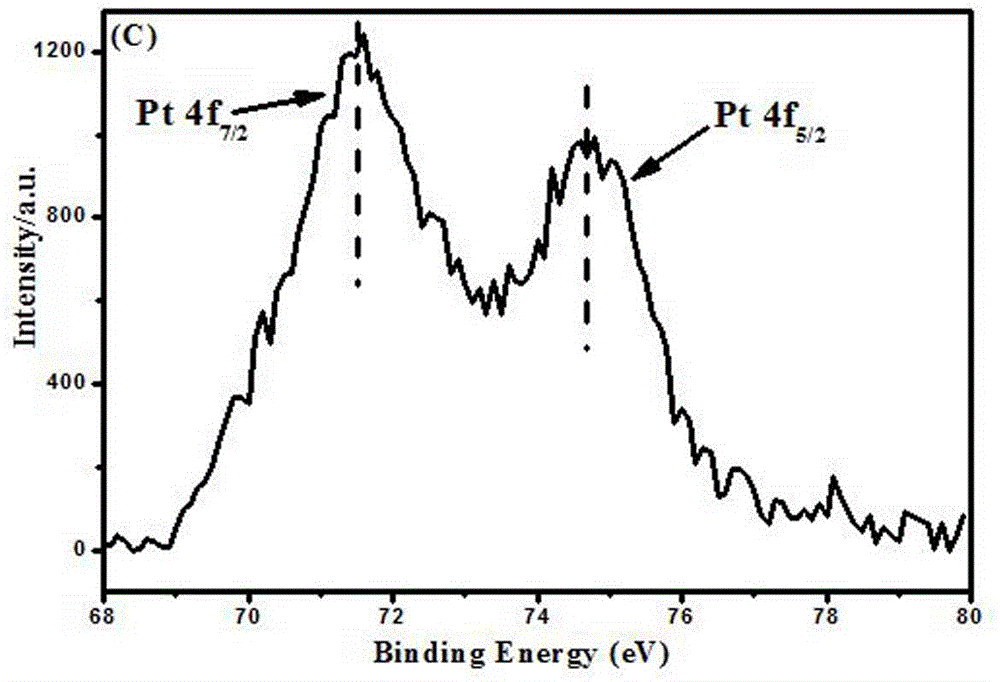

[0026] Metal platinum is loaded on the inner wall of the Beta molecular sieve shell structure, and the metal platinum accounts for 0.1wt% of the total weight of the spherical ceria and the Beta molecular sieve shell structure.

[0027] The above-mentioned preparation method of the microreactor applied to the steam reforming reaction of ethanol comprises the following steps:

[0028] Take 380mL of deionized water, 25g of cerium nitrate, and 12g of polyvinylpyrrolidone, add them together into a polytetrafluoroethylene container, stir at room temperature for 3 hours, and form a transparent solution; put the polytetrafluoroethylene container containing the mixed transparent solution into a stainless steel ...

Embodiment 2

[0041] A microreactor applied to the steam reforming reaction of ethanol, including 65wt% spherical ceria and 35wt% Beta molecular sieve shell structure, the Beta molecular sieve shell structure is wrapped outside the spherical ceria, and there is a Insulate hollow structures;

[0042] Metal platinum is loaded on the inner wall of the Beta molecular sieve shell structure, and the metal platinum accounts for 3 wt% of the total weight of the spherical ceria and the Beta molecular sieve shell structure.

[0043] The above-mentioned preparation method of the microreactor applied to the steam reforming reaction of ethanol comprises the following steps:

[0044] Take 400mL of deionized water, 21.82g of cerium nitrate, and 11.114g of polyvinylpyrrolidone, and add them together into a polytetrafluoroethylene container, and stir at room temperature for 3 hours to form a transparent solution; put the polytetrafluoroethylene container containing the mixed transparent solution into a stai...

Embodiment 3

[0054] A microreactor applied to the steam reforming reaction of ethanol, including 68wt% spherical ceria and 32wt% Beta molecular sieve shell structure, Beta molecular sieve shell structure is wrapped outside the spherical ceria, and there is a Insulate hollow structures;

[0055] Metal platinum is loaded on the inner wall of the Beta molecular sieve shell structure, and the metal platinum accounts for 1 wt% of the total weight of the spherical ceria and the Beta molecular sieve shell structure.

[0056] The above-mentioned preparation method of the microreactor applied to the steam reforming reaction of ethanol comprises the following steps:

[0057]Take 400 mL of deionized water, 30 g of cerium chloride, and 12 g of polyvinylpyrrolidone, add them together into a polytetrafluoroethylene container, stir at room temperature for 3 h, and form a transparent solution; put the polytetrafluoroethylene container containing the mixed transparent solution into Put it into a stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com