Preparation method titanium-based polyaniline-doped lead dioxide composite electrode material

A composite electrode and lead dioxide technology, applied in chemical instruments and methods, water treatment parameter control, water pollutants, etc., can solve the problem of large doping amount of PTFE resistivity, current efficiency and energy consumption of composite electrode conductive organic wastewater Adverse effects and other issues can be achieved to reduce process complexity, avoid uncertainty, and increase feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

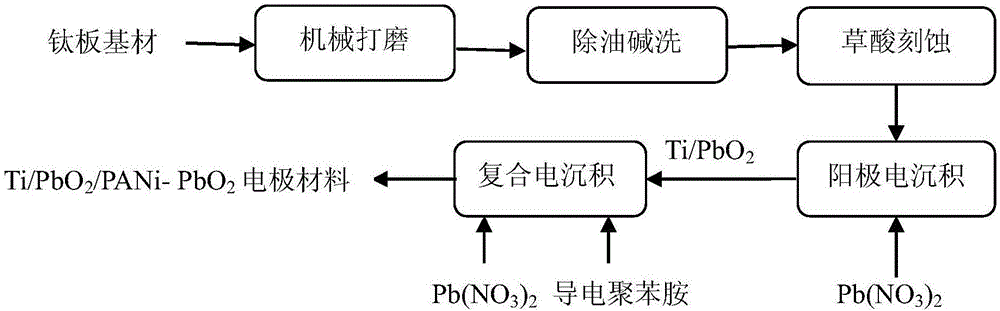

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment adopts the Ti / PbO prepared by the method of the present invention 2 / PANi-PbO 2 The composite electrode material is the anode, the stainless steel plate with the same area is the cathode, and the distance between the plates is 3cm, and the electrochemical oxidation and degradation treatment of the simulated phenol wastewater is carried out. The volume of the simulated wastewater is 150ml, the initial concentration of phenol is 100mg / L, at 10mA / cm 2 After 180 minutes under the action of electric current, the removal rate of phenol reaches 95.24%, and the removal rate of COD is 55%, which is higher than that of general PbO without polyaniline 2 Electrodes improved by 10%.

Embodiment 2

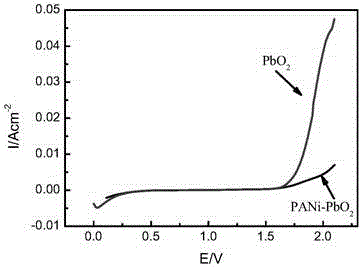

[0028] In this embodiment, the electrochemical polarization curve test is carried out on the electrode material prepared by the method of the present invention. The test uses a platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode, at a current density of 1A / cm 2 , the electrolyte is 1M H 2 SO 4 solution, at a temperature of 30 °C, and with general PbO of undoped PANI 2 Electrodes were compared and the results were as follows Figure 5 shown. It can be seen that the oxygen evolution potential of the electrode prepared by the method of the present invention is positively shifted, and the oxygen evolution current is reduced, indicating that polyaniline doping can effectively improve the concentration of PbO. 2 The oxygen evolution overpotential of the electrode can inhibit the occurrence of oxygen evolution side reactions.

Embodiment 3

[0030] In this embodiment, the electrode material prepared by the method of the present invention is the anode, the stainless steel plate is the cathode, and the distance between the plates is 4cm, placed in a plexiglass electrolytic cell, containing 300ml of H at a concentration of 1mol / L in the cell 2 SO 4 solution, connected to a DC power supply, at a current density of 10mA / cm 2 , after polarizing for 12 hours at 30°C, samples were taken, and the concentration of lead dissolved in the solution during the anodic polarization was detected by a graphite furnace atomic absorption spectrometer. Based on this, the dissolution stability of the electrode was evaluated, and compared with the general PbO 2 Electrodes and doping 6.0g L -1 PTFE-PbO 2 electrodes for comparison. The experimental results show that the average dissolution rate of lead under the anodic polarization of the electrode prepared by the method of the present invention is 1.417×10 -3 mg·h -1 cm -2 , while ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com