Synthesizing method of benzofuranone compound containing sulfonyl

A technology of benzofuranone and synthesis method, which is applied in directions such as organic chemistry and achieves the effects of mild conditions, safe operation and wide range of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

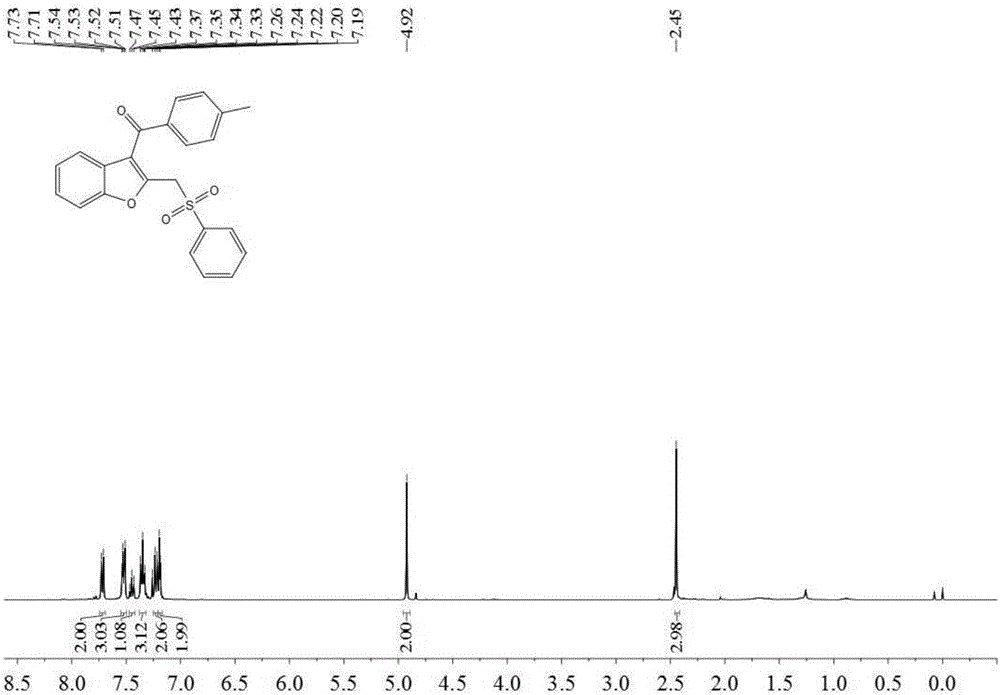

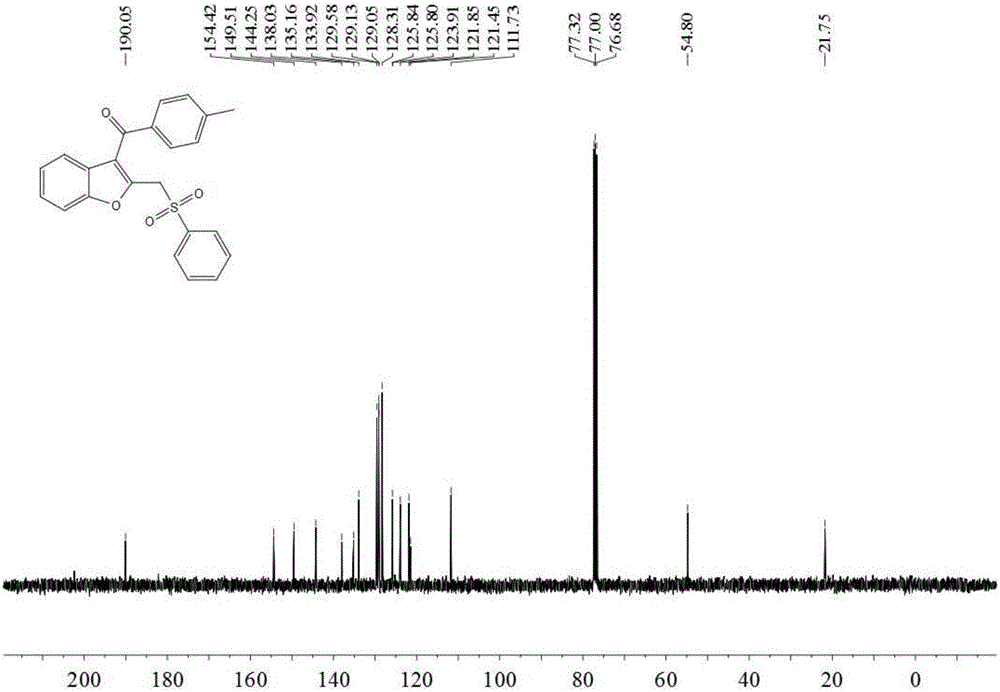

Embodiment 1

[0033] Add 0.3 mmol 2-(4-methylphenylethynyl) phenyl alkenyl ether (M.Hu, R-J.Song and J-H, Li, Angew.Chem.Int.Ed.2015,54,608– 612), 0.6 mmol of sodium benzene sulfinate, 0.06 mmol of silver nitrate, 0.6 mmol of potassium persulfate and 3 milliliters of acetonitrile, stirred and reacted at 80 degrees Celsius at 700 rpm for 4 hours, and stopped stirring. Add 4 mL of water, extract 3 times with ethyl acetate, combine the organic phases and use 0.5 g of anhydrous magnesium sulfate to dry, filter, evaporate the solvent under reduced pressure, and then separate and purify by column chromatography to obtain the target product. The eluent was petroleum ether: ethyl acetate mixed solvent with a volume ratio of 8:1, and the yield was 74%.

[0034] The hydrogen spectrogram and the carbon spectrogram of the product obtained in this embodiment are respectively as follows figure 1 and figure 2 shown; the structural characterization data are shown below:

[0035] 1 H NMR (400MHz, CDCl ...

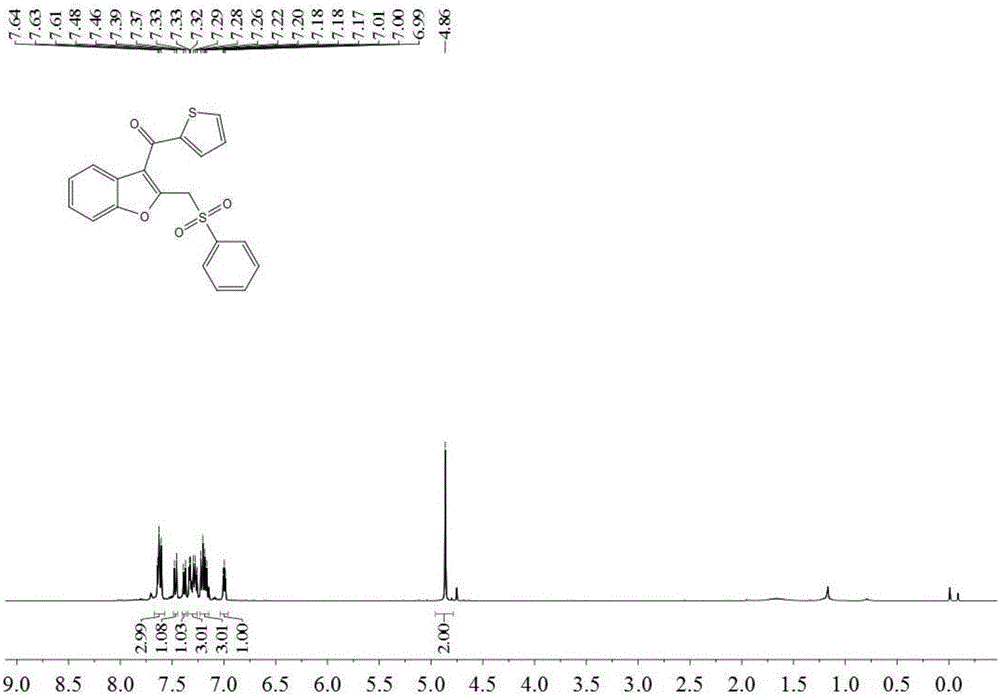

Embodiment 2

[0042]Add 0.3 mmol 2-thienylphenyl alkenyl ether (M.Hu, R-J. Song and J-H, Li, Angew. Chem. Int. Ed. 2015, 54, 608–612), 0.6 mmol phenylene oxide into the reaction tube Sodium sulfonate, 0.06 mmol of silver nitrate, 0.6 mmol of potassium persulfate and 3 ml of acetonitrile were stirred and reacted at 80 degrees Celsius at 700 rpm for 6 hours, and the stirring was stopped. Add 4 mL of water, extract 3 times with ethyl acetate, combine the organic phases and use 0.5 g of anhydrous magnesium sulfate to dry, filter, evaporate the solvent under reduced pressure, and then separate and purify by column chromatography to obtain the target product. The eluent was petroleum ether:ethyl acetate mixed solvent with a volume ratio of 5:1, and the yield was 62%.

[0043] The hydrogen spectrogram and the carbon spectrogram of the product obtained in this embodiment are respectively as follows image 3 and Figure 4 shown; the structural characterization data are shown below:

[0044] 1 H ...

Embodiment 3

[0051] Add 0.3 mmol 5-chloro-2-phenylethynylphenyl alkenyl ether (M.Hu, R-J. Songand J-H, Li, Angew. Chem. Int. Ed. 2015, 54, 608–612), 0.6 Millimole sodium benzenesulfinate, 0.06 mmol silver nitrate, 0.6 mmol potassium persulfate and 4 milliliters of acetonitrile were stirred and reacted at 80 degrees Celsius at 700 rpm for 4 hours, and the stirring was stopped. Add 4 mL of water, extract 3 times with ethyl acetate, combine the organic phases and use 0.5 g of anhydrous magnesium sulfate to dry, filter, evaporate the solvent under reduced pressure, and then separate and purify by column chromatography to obtain the target product. The eluent was petroleum ether:ethyl acetate mixed solvent with a volume ratio of 6:1, and the yield was 62%.

[0052] The hydrogen spectrogram and the carbon spectrogram of the product obtained in this embodiment are respectively as follows Figure 5 and Figure 6 shown; the structural characterization data are shown below:

[0053] 1 H NMR (400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com