Composite plant enzyme as well as preparation method and application thereof

The technology of plant enzyme and compound enzyme is applied in the field of compound plant enzyme and its preparation, which can solve the problems of insufficient dissolution of active ingredients, waste of raw materials, pollution of other miscellaneous bacteria, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

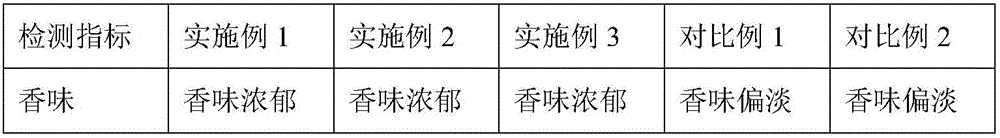

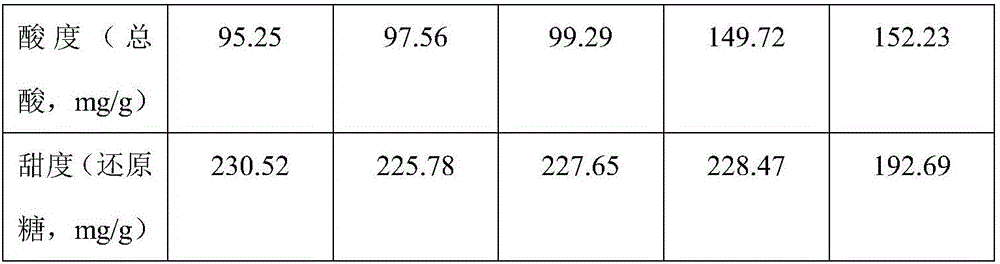

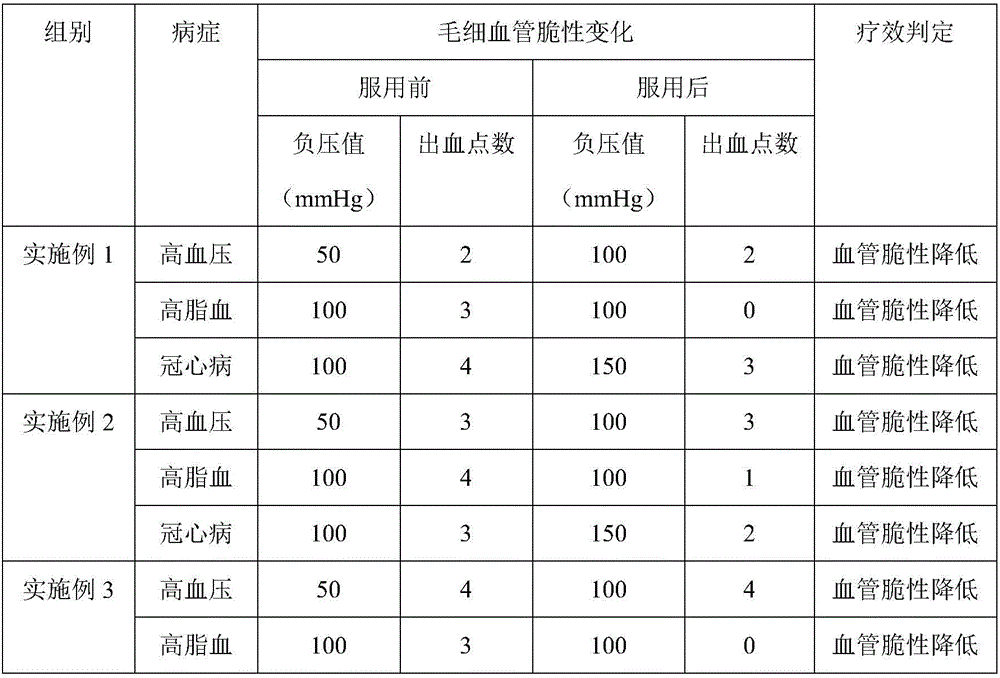

Examples

Embodiment 1

[0031] The preparation method of the embodiment of the present invention 1 composite plant enzyme comprises the following steps:

[0032] (1) Grind buckwheat, oats, brown rice, tartary buckwheat bran and wheat germ into powder, pass through a 200-mesh sieve to obtain miscellaneous grain powder, add water to the miscellaneous grain powder according to the ratio of material to liquid ratio of 1:10, and use sodium carbonate The pH of the solution is adjusted to 6, and a compound enzyme is added. The compound enzyme is composed of β-glucanase and amylase in a weight ratio of 0.8:0.3, and the amount of the compound enzyme added is 0.8g / kg miscellaneous grain powder. Carry out enzymatic hydrolysis for 6 hours, then raise the temperature to 100°C and keep it warm for 10 minutes to stop the enzymatic hydrolysis, cool at room temperature, and then centrifuge to obtain the supernatant and grain solids respectively for later use;

[0033] (2) After ozone sterilizing the grain solids obta...

Embodiment 2

[0041] The preparation method of the embodiment of the present invention 2 composite plant enzymes comprises the following steps:

[0042] (1) Grind buckwheat, oats, brown rice, tartary buckwheat bran and wheat germ into powder, pass through a 200-mesh sieve to obtain miscellaneous grain powder, add water to the miscellaneous grain powder according to the ratio of material to liquid ratio of 1:10, and use sodium carbonate Adjust the pH of the solution to 6, add a compound enzyme, the compound enzyme is composed of β-glucanase and amylase in a weight ratio of 0.5:0.2, the amount of the compound enzyme added is 0.5g / kg miscellaneous grain powder, at 50°C Carry out enzymatic hydrolysis for 6 hours, then raise the temperature to 100°C and keep it warm for 10 minutes to stop the enzymatic hydrolysis, cool at room temperature, and then centrifuge to obtain the supernatant and grain solids respectively for later use;

[0043] (2) After ozone sterilizing the grain solids obtained in s...

Embodiment 3

[0051] The preparation method of the embodiment of the present invention 3 composite plant enzymes comprises the following steps:

[0052] (1) Grind buckwheat, oats, brown rice, tartary buckwheat bran and wheat germ into powder, pass through a 150-mesh sieve to obtain miscellaneous grain powder, add water to the miscellaneous grain powder according to the ratio of material to liquid ratio of 1:10, and use sodium carbonate Adjust the pH of the solution to 7, add a compound enzyme, the compound enzyme is composed of β-glucanase and amylase in a weight ratio of 0.7:0.4, the amount of the compound enzyme added is 1.2g / kg miscellaneous grain powder, at 55°C Carry out enzymatic hydrolysis for 8 hours, then raise the temperature to 100°C and keep it warm for 15 minutes to stop the enzymatic hydrolysis, cool at room temperature, and then centrifuge to obtain the supernatant and grain solids respectively for later use;

[0053] (2) After the miscellaneous grain solid matter obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com