Method using biochar-based microalgae composite absorbent to remove heavy metals

A composite adsorption and biochar technology, applied in the field of water pollution control, can solve the problems of secondary environmental pollution by sediments and toxic compounds, insignificant water source effect, and high operating costs, achieve good adsorption effect, extensive removal and recovery, and improve The effect of adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

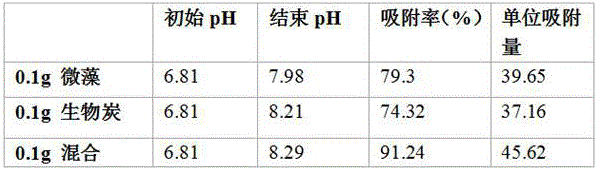

Examples

Embodiment 1

[0041] (1) After crushing the stems and leaves of sun-dried water hyacinth, crack them for 210 seconds under the conditions of cracking power of 1100W and cracking temperature of 500°C. After cooling to room temperature, grind and sieve to obtain biochar with a particle size of 3mm. Take 0.1g for separate adsorption and 0.02g for mixed adsorption with microalgae; dry in an oven at 105°C for 24 hours for later use;

[0042] (2) The algae species were selected from the freshwater algae species bank of the Institute of Hydrobiology, Chinese Academy of Sciences Scenedesmus dimorphus ,, culture light intensity 120 µmol photons / m 2 / s, pH is 7, temperature is 26 After culturing at 5°C for 8 days, the biomass concentration DW2 in the microalgae stock solution was measured to be 0.82 g / L. The volume of the algae solution was 122ml (corresponding to the mass of the microalgae being 0.1g), and the volume of the algae solution was 97ml (corresponding to the mass of the microalgae bein...

Embodiment 2

[0050] (1) Take sun-dried rice husks and crush them, then crack them for 210 seconds under the conditions of cracking power of 800W and cracking temperature of 600°C. After cooling to room temperature, grind and sieve to obtain biochar with a particle size of 2mm. Take 0.1g respectively For single adsorption (0.1BC), take 0.06g for single adsorption (0.06BC) and mixed adsorption of microalgae; dry in an oven at 105°C for 24 hours for later use;

[0051] (2) The algae species are Chlorella from the Freshwater Algae Species Bank of the Institute of Hydrobiology, Chinese Academy of Sciences Chlorella vugaris , culture light intensity 200 µmol photons / m 2 / s, pH is 8, temperature is 26 5°C, after 16 days of culture, the biomass concentration DW2 in the microalgae stock solution was measured to be 1.5 g / L, and the volume of the algae liquid was 66ml (corresponding to the mass of the microalgae being 0.1g) for separate adsorption and 26ml (corresponding to the mass of the microal...

Embodiment 3

[0057] (1) After the stems and leaves of dried water hyacinth were crushed, they were cracked for 210 seconds at a cracking power of 1100W and a cracking temperature of 500°C. After cooling to room temperature, they were ground and sieved to produce biochar with different particle sizes (1mm, 3mm, 5mm), take 0.02g for mixed adsorption with microalgae; dry in an oven at 105°C for 24 hours for later use;

[0058] (2) The algae species are Chlorella from the Freshwater Algae Species Bank of the Institute of Hydrobiology, Chinese Academy of Sciences Chlorella vugaris , culture light intensity 120 µmol photons / m 2 / s, pH is 7, temperature is 26 After 10 days of culture at 5°C, the biomass concentration DW2 in the microalgae stock solution was measured to be 1 g / L. Take 100ml of the algae liquid (corresponding to 0.1g of microalgae mass) and 80ml (corresponding to 0.08g of microalgae mass) with the biological charcoal for mixing;

[0059] (3) Add 0.02g of biochar of various par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com