Collapse-easy water glass core sand for casting train aluminum alloy castings and preparation method thereof

A technology of aluminum alloy castings and water glass, which is applied in the field of foundry industry, can solve problems such as large consumption, increased cost of castings, and toxic gas pollution, so as to improve wet compressive strength and hot-wet tensile strength, improve casting yield, and improve The effect of interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A collapsible sodium silicate core sand for train aluminum alloy castings, which is prepared from the following raw materials in parts by weight (kg): olivine sand 140, garnet sand 30, allophane 20, siltstone 30, calcined kaolin 15. Asbestos leftovers 8, beryllium oxide 6, boiling slag 12, water glass 8, sodium metaaluminate 2, alumite powder 1, hydroxypropyl distarch phosphate 2, propylene glycol alginate 2, microcrystalline paraffin 4, Ferrosilicon powder 5, zirconium oxychloride 3, sodium sulfamate 4, sodium hexametaphosphate 5, appropriate amount of water.

[0016] A preparation method for collapsible sodium silicate core sand for casting aluminum alloy castings for trains, comprising the following steps:

[0017] (1) Mix the boiling slag, allophane, and siltstone evenly, break it into 60-80 mesh particle size, and then send it to a calcination furnace at 1200-1300°C for 2-4 hours, take it out and add olivine sand and pomegranate while it is hot Dry mixing of stone...

Embodiment 2

[0021] A collapsible sodium silicate core sand for train aluminum alloy castings, which is prepared from the following raw materials in parts by weight (kg): olivine sand 145, garnet sand 35, allophane 25, siltstone 32.5, calcined kaolin 17.5, asbestos waste 9, beryllium oxide 7, boiling slag 13, water glass 9, sodium metaaluminate 3, parenite powder 1.5, hydroxypropyl distarch phosphate 3, propylene glycol alginate 2.5, microcrystalline paraffin 5, Ferrosilicon powder 6.5, zirconium oxychloride 4, sodium sulfamate 5, sodium hexametaphosphate 6, appropriate amount of water.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] A collapsible sodium silicate core sand for train aluminum alloy castings, which is prepared from the following raw materials in parts by weight (kg): olivine sand 150, garnet sand 40, allophane 30, siltstone 35, calcined kaolin 20. Asbestos scraps 10, beryllium oxide 8, boiling slag 14, water glass 10, sodium metaaluminate 4, alumite powder 2, hydroxypropyl distarch phosphate 4, propylene glycol alginate 3, microcrystalline paraffin 6, Ferrosilicon powder 8, zirconium oxychloride 5, sodium sulfamate 6, sodium hexametaphosphate 7, appropriate amount of water.

[0025] The preparation method is the same as in Example 1.

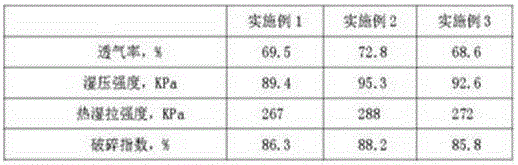

[0026] The performance testing result of the easily collapsible sodium silicate core sand for the train aluminum alloy casting casting that above-mentioned embodiment 1-3 makes is shown in the table below:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com