Method for preparing acrylate-modified waterborne polyurethane from soybean oil polyalcohol

A technology of soybean oil polyol and water-based polyurethane, which is applied in the field of polymer materials, can solve the problems of not meeting the sustainable development of green chemical industry, and the products are not easy to degrade, and achieve the effects of low brittleness, low odor and high degree of branching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

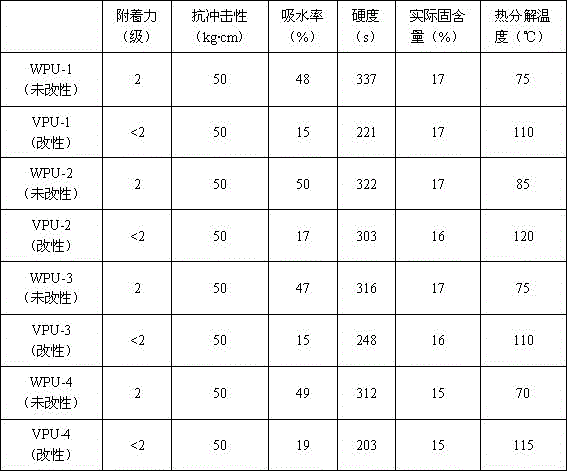

Image

Examples

Embodiment 1

[0022] (1) Synthesis of halogenated soybean oil polyols: add 40g of hydrochloric acid and 150ml of acetone into a 500ml flask and mix; at 45°C, add 60.2g of epoxy soybean oil dropwise into the flask and stir for 15 minutes ; The mixture was stirred and reacted at 40°C for 2 hours; then, 150ml of ethyl acetate and 100ml of deionized water were added to separate the layers, and the layered organic layer was washed with sodium bicarbonate solution until the pH was 8, and then, The washed organic layer was dried with magnesium sulfate and filtered, and the solvent was distilled off under reduced pressure to obtain a yellow viscous liquid halogenated soybean oil polyol; the hydroxyl value of the obtained halogenated soybean oil polyol was 137.78 mgKOH / g, and the acid value was 7.5 mgKOH / g. g.

[0023] (2) Synthesis of acrylic epoxidized soybean oil AESO: 120g epoxidized soybean oil and 0.226g inhibitor nitroxide radical piperidinol 4-OH-TEMPO were added to a 500ml three-necked flas...

Embodiment 2

[0027] (1) Synthesis of halogenated soybean oil polyols: add 40g of hydrochloric acid and 150ml of acetone into a 500ml flask and mix; at 45°C, add 63.0g of epoxy soybean oil dropwise into the flask and stir for 15 minutes The mixture was stirred and reacted at 40°C for 4 hours; then, 150ml of ethyl acetate and 100ml of deionized water were added, and the layers were separated, and the layered organic layer was washed with sodium bicarbonate solution until the pH was 7, and then, The washed organic layer was dried with magnesium sulfate and filtered, and the solvent was distilled off under reduced pressure to obtain a yellow viscous liquid halogenated soybean oil polyol; the hydroxyl value of the obtained halogenated soybean oil polyol was 133.63 mgKOH / g, and the acid value was 7.8 mgKOH / g g.

[0028](2) Synthesis of acrylic epoxidized soybean oil AESO: Add 120g of epoxidized soybean oil and 0.223g of inhibitor nitroxide radical piperidinol 4-OH-TEMPO into a 500ml three-necked...

Embodiment 3

[0032] (1) Synthesis of halogenated soybean oil polyols: add 40g of hydrochloric acid and 150ml of acetone into a 500ml flask and mix; at 45°C, add 63.1g of epoxy soybean oil dropwise into the flask and stir for 15 minutes ; The mixture was stirred and reacted at 40°C for 3 hours; then, 150ml of ethyl acetate and 100ml of deionized water were added to separate the layers, and the layered organic layer was washed with sodium bicarbonate solution until the pH was 8, and then, The washed organic layer was dried with magnesium sulfate and filtered, and the solvent was distilled off under reduced pressure to obtain a yellow viscous liquid halogenated soybean oil polyol; the hydroxyl value of the obtained halogenated soybean oil polyol was 129.6 mgKOH / g, and the acid value was 6.8 mgKOH / g. g.

[0033] (2) Synthesis of acrylic epoxy soybean oil AESO: Add 120g of epoxy soybean oil and 0.224g of polymerization inhibitor nitroxide free radical piperidinol 4-OH-TEMPO into a 500ml three-n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com